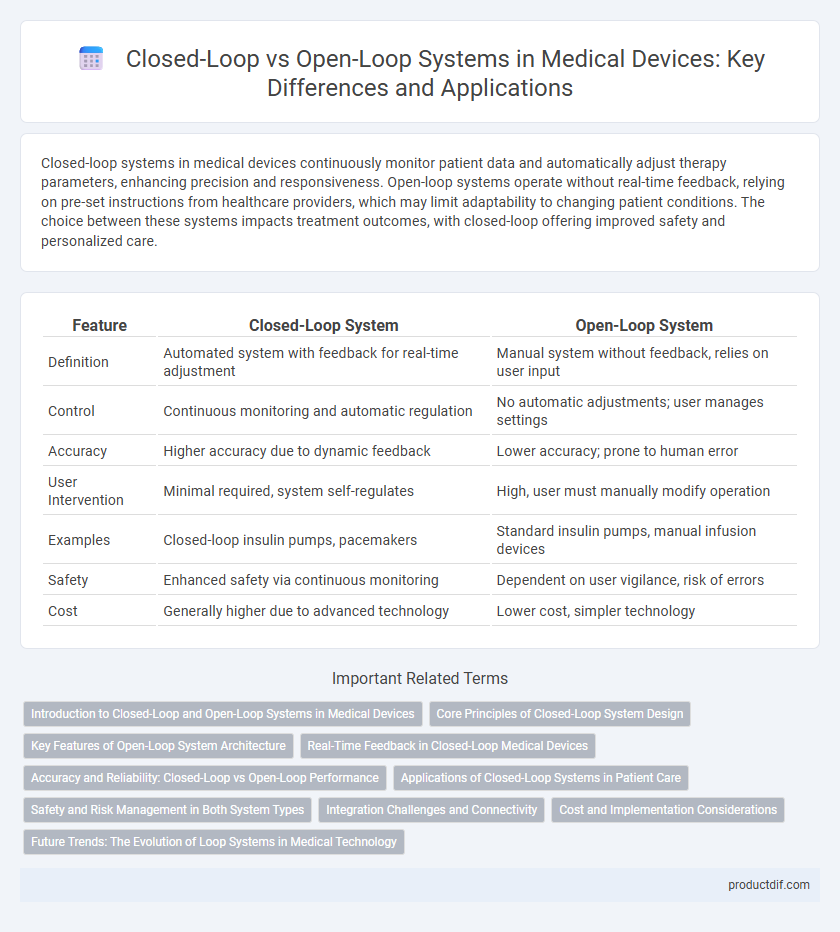

Closed-loop systems in medical devices continuously monitor patient data and automatically adjust therapy parameters, enhancing precision and responsiveness. Open-loop systems operate without real-time feedback, relying on pre-set instructions from healthcare providers, which may limit adaptability to changing patient conditions. The choice between these systems impacts treatment outcomes, with closed-loop offering improved safety and personalized care.

Table of Comparison

| Feature | Closed-Loop System | Open-Loop System |

|---|---|---|

| Definition | Automated system with feedback for real-time adjustment | Manual system without feedback, relies on user input |

| Control | Continuous monitoring and automatic regulation | No automatic adjustments; user manages settings |

| Accuracy | Higher accuracy due to dynamic feedback | Lower accuracy; prone to human error |

| User Intervention | Minimal required, system self-regulates | High, user must manually modify operation |

| Examples | Closed-loop insulin pumps, pacemakers | Standard insulin pumps, manual infusion devices |

| Safety | Enhanced safety via continuous monitoring | Dependent on user vigilance, risk of errors |

| Cost | Generally higher due to advanced technology | Lower cost, simpler technology |

Introduction to Closed-Loop and Open-Loop Systems in Medical Devices

Closed-loop systems in medical devices continuously monitor patient data and automatically adjust therapy based on real-time feedback, enhancing precision and personalized care. Open-loop systems deliver pre-set treatments without feedback integration, relying on manual adjustments by healthcare providers. The increasing adoption of closed-loop technology improves clinical outcomes by enabling adaptive responses to physiological changes.

Core Principles of Closed-Loop System Design

Closed-loop system design in medical devices centers on real-time feedback control, where sensors continuously monitor physiological parameters and automatically adjust therapeutic delivery to maintain target levels. This adaptive mechanism enhances precision and responsiveness compared to open-loop systems, which operate on preset, non-adjustable inputs without patient feedback. Core principles include sensor accuracy, algorithm robustness, and safety redundancies to ensure reliable, autonomous system performance in dynamic biological environments.

Key Features of Open-Loop System Architecture

Open-loop system architecture in medical devices operates without feedback from the output, relying solely on preset commands for control actions. Key features include simplicity in design, reduced cost, and ease of implementation, but they lack adaptability and real-time response to physiological changes. These systems are commonly used in applications where precise feedback is unnecessary or unavailable, such as basic infusion pumps or standardized ventilators.

Real-Time Feedback in Closed-Loop Medical Devices

Closed-loop medical devices continuously monitor patient data and automatically adjust therapy in real-time, enhancing precision and responsiveness compared to open-loop systems which operate without feedback. Real-time feedback enables rapid detection of physiological changes, improving outcomes in applications such as insulin pumps and neurostimulators. This dynamic adjustment reduces risks of under- or overtreatment, optimizing safety and efficacy in patient care.

Accuracy and Reliability: Closed-Loop vs Open-Loop Performance

Closed-loop systems in medical devices offer enhanced accuracy and reliability by continuously monitoring feedback and adjusting control parameters in real-time, reducing the risk of errors and improving patient outcomes. Open-loop systems lack this feedback mechanism, often leading to inconsistent performance and increased potential for inaccuracies during treatment or monitoring. Enhanced sensor integration and adaptive algorithms in closed-loop systems ensure more precise medication dosing and timely response to physiological changes compared to open-loop configurations.

Applications of Closed-Loop Systems in Patient Care

Closed-loop systems in medical devices enable real-time monitoring and automatic adjustment of therapies, enhancing precision in patient care management. These systems are extensively used in insulin pumps for diabetes management, where continuous glucose monitoring informs insulin delivery to maintain optimal blood sugar levels. The application of closed-loop technology also extends to cardiac pacemakers and anesthesia delivery systems, improving patient outcomes through responsive treatment adjustments based on physiological feedback.

Safety and Risk Management in Both System Types

Closed-loop systems in medical devices enhance patient safety by continuously monitoring physiological parameters and autonomously adjusting therapy, reducing human error and enabling real-time risk mitigation. In contrast, open-loop systems rely on pre-set instructions without feedback integration, increasing the potential for delayed response to adverse events and higher risk exposure. Effective risk management in both systems requires rigorous validation, continuous monitoring, and fail-safe mechanisms tailored to their operational design to prevent harm and ensure compliance with regulatory standards.

Integration Challenges and Connectivity

Closed-loop medical device systems face significant integration challenges due to the need for real-time data exchange and precise communication between sensors, controllers, and actuators, ensuring accurate feedback and automated adjustments. Open-loop systems, by contrast, operate without feedback integration, simplifying connectivity but lacking dynamic response capabilities, which limits their adaptability in complex clinical environments. Interoperability standards such as HL7 and IEEE 11073 are critical for achieving seamless connectivity and data synchronization in closed-loop systems, facilitating enhanced patient monitoring and therapeutic outcomes.

Cost and Implementation Considerations

Closed-loop medical device systems generally incur higher upfront costs due to advanced sensors and control algorithms, while open-loop systems are more cost-effective with simpler implementation. Closed-loop systems require intricate calibration and ongoing maintenance to ensure real-time feedback accuracy, increasing long-term operational expenses. Open-loop systems, although less adaptive, benefit from easier implementation and lower initial investment, making them suitable for limited-budget healthcare settings.

Future Trends: The Evolution of Loop Systems in Medical Technology

Closed-loop systems in medical technology are advancing with the integration of artificial intelligence and real-time data analytics, enabling personalized and adaptive treatment protocols for chronic conditions like diabetes. Open-loop systems, while simpler and more cost-effective, are evolving through enhanced user interfaces and connectivity features to improve patient compliance and monitoring. Future trends indicate a shift towards hybrid models combining the reliability of open-loop with the autonomy of closed-loop, driven by innovations in sensor accuracy and machine learning algorithms.

Closed-Loop System vs Open-Loop System Infographic

productdif.com

productdif.com