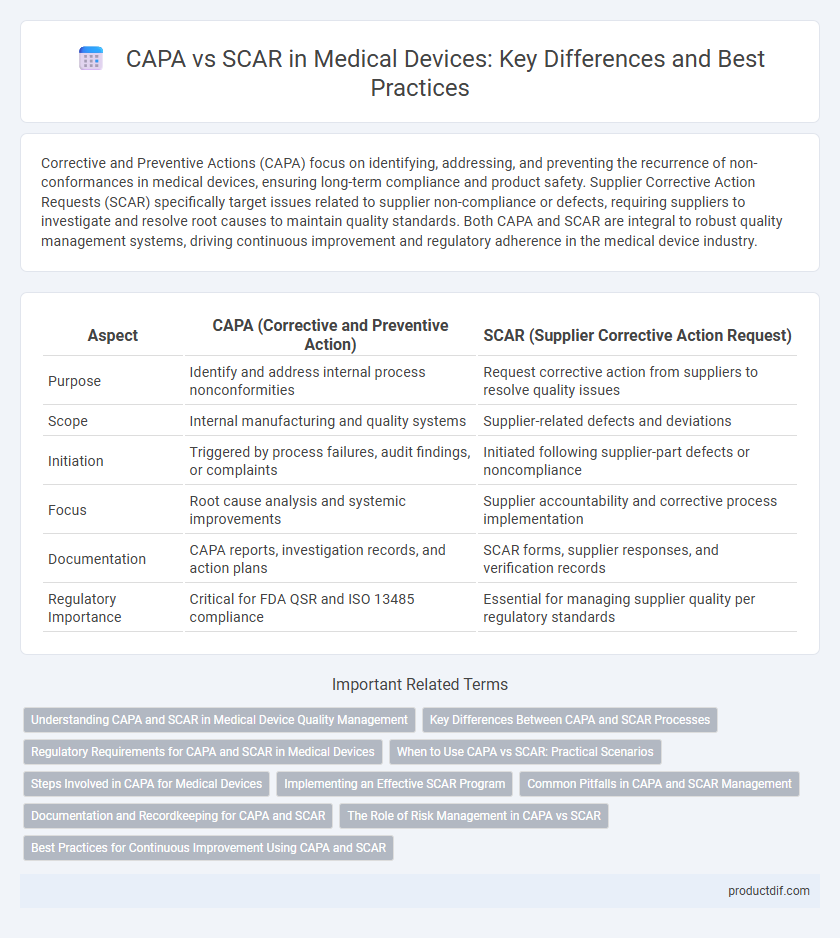

Corrective and Preventive Actions (CAPA) focus on identifying, addressing, and preventing the recurrence of non-conformances in medical devices, ensuring long-term compliance and product safety. Supplier Corrective Action Requests (SCAR) specifically target issues related to supplier non-compliance or defects, requiring suppliers to investigate and resolve root causes to maintain quality standards. Both CAPA and SCAR are integral to robust quality management systems, driving continuous improvement and regulatory adherence in the medical device industry.

Table of Comparison

| Aspect | CAPA (Corrective and Preventive Action) | SCAR (Supplier Corrective Action Request) |

|---|---|---|

| Purpose | Identify and address internal process nonconformities | Request corrective action from suppliers to resolve quality issues |

| Scope | Internal manufacturing and quality systems | Supplier-related defects and deviations |

| Initiation | Triggered by process failures, audit findings, or complaints | Initiated following supplier-part defects or noncompliance |

| Focus | Root cause analysis and systemic improvements | Supplier accountability and corrective process implementation |

| Documentation | CAPA reports, investigation records, and action plans | SCAR forms, supplier responses, and verification records |

| Regulatory Importance | Critical for FDA QSR and ISO 13485 compliance | Essential for managing supplier quality per regulatory standards |

Understanding CAPA and SCAR in Medical Device Quality Management

CAPA (Corrective and Preventive Action) and SCAR (Supplier Corrective Action Request) are essential components in medical device quality management, addressing nonconformities and supplier-related issues respectively. CAPA focuses on identifying root causes of defects, implementing corrective actions, and preventing recurrence within the organization, ensuring compliance with FDA and ISO 13485 standards. SCAR specifically targets supplier performance by requiring corrective actions to resolve defects caused by external vendors, enhancing supply chain quality and regulatory adherence.

Key Differences Between CAPA and SCAR Processes

CAPA (Corrective and Preventive Action) focuses on identifying root causes and implementing systemic improvements to prevent recurrence of quality issues, while SCAR (Supplier Corrective Action Request) targets supplier-specific nonconformities requiring corrective actions. CAPA encompasses both corrective and preventive measures internally within an organization, whereas SCAR is a supplier management tool aimed at resolving external supplier deviations. Key differences include scope, responsibility, and process triggers, with CAPA driven by internal quality audits and product failures, and SCAR initiated through supplier performance discrepancies.

Regulatory Requirements for CAPA and SCAR in Medical Devices

Corrective and Preventive Action (CAPA) and Supplier Corrective Action Request (SCAR) are crucial components in medical device quality management systems, each governed by regulatory standards such as FDA 21 CFR Part 820 and ISO 13485. CAPA mandates a systematic approach to identifying, investigating, and resolving nonconformities within the device lifecycle to ensure product safety and compliance. SCAR is specifically focused on addressing supplier-related issues and requires documented evidence of corrective measures to meet stringent supplier quality requirements and regulatory audits.

When to Use CAPA vs SCAR: Practical Scenarios

Corrective and Preventive Actions (CAPA) are used when addressing systemic quality issues that require investigation and long-term solutions, such as recurrent non-conformities in a medical device manufacturing process. Supplier Corrective Action Requests (SCAR) apply specifically to supplier-related problems that impact product quality, such as defects in raw materials or components received. Use CAPA when internal process improvements are needed, and SCAR when external suppliers must implement corrective measures to prevent future defects.

Steps Involved in CAPA for Medical Devices

The Corrective and Preventive Action (CAPA) process for medical devices involves identifying nonconformities, conducting root cause analysis, and implementing corrective measures to eliminate the sources of defects. Key steps include defining the problem, evaluating risk impact, developing action plans, verifying effectiveness, and documenting outcomes in compliance with FDA 21 CFR Part 820. Effective CAPA management ensures continuous product quality improvement and regulatory adherence in medical device manufacturing.

Implementing an Effective SCAR Program

Implementing an effective Supplier Corrective Action Request (SCAR) program enhances quality management in medical device manufacturing by systematically addressing supplier-related nonconformities. Integrating SCAR with Corrective and Preventive Action (CAPA) processes ensures root cause analysis and timely resolution, reducing risks associated with device failures and regulatory non-compliance. Leveraging ISO 13485 and FDA 21 CFR Part 820 guidelines optimizes SCAR effectiveness, improving supplier performance and overall product safety.

Common Pitfalls in CAPA and SCAR Management

Common pitfalls in CAPA and SCAR management include inadequate root cause analysis, leading to recurring nonconformities and delayed corrective actions. Poor documentation and ineffective communication between quality, manufacturing, and suppliers hinder timely resolution of issues. Failure to monitor the effectiveness of implemented actions results in unresolved problems and compliance risks in medical device manufacturing.

Documentation and Recordkeeping for CAPA and SCAR

CAPA (Corrective and Preventive Action) documentation requires detailed records of root cause analysis, action plans, verification activities, and effectiveness checks to ensure compliance with FDA and ISO 13485 standards. SCAR (Supplier Corrective Action Request) documentation focuses on supplier-related nonconformities, including evidence of supplier communication, corrective actions taken, and follow-up verification to maintain supplier quality management. Both CAPA and SCAR records must be meticulously maintained and readily accessible during audits to demonstrate traceability and regulatory adherence.

The Role of Risk Management in CAPA vs SCAR

Risk management in CAPA (Corrective and Preventive Action) involves identifying, assessing, and mitigating risks associated with nonconformities to ensure product safety and compliance. In SCAR (Supplier Corrective Action Request), risk management focuses on evaluating supplier-related risks and implementing corrective actions to prevent recurrence of quality issues affecting the supply chain. Effective integration of risk management in both CAPA and SCAR enhances proactive resolution and continuous improvement in medical device manufacturing.

Best Practices for Continuous Improvement Using CAPA and SCAR

Effective continuous improvement in medical device quality management relies on integrating CAPA (Corrective and Preventive Actions) and SCAR (Supplier Corrective Action Requests) to address internal and supplier-related nonconformities. Best practices include establishing clear root cause analysis, setting measurable corrective actions, and ensuring timely verification of effectiveness to prevent recurrence and enhance product safety. Leveraging data analytics and cross-functional collaboration drives proactive risk mitigation and supplier performance optimization.

CAPA vs SCAR Infographic

productdif.com

productdif.com