Polymer-based medical devices offer superior flexibility and biocompatibility compared to metal-based devices, reducing the risk of tissue irritation and allergic reactions. These devices are lightweight and can be easily molded into complex shapes, enhancing patient comfort and customization options. Metal-based devices provide exceptional strength and durability, making them ideal for load-bearing applications but may cause imaging artifacts and corrosion concerns in the body.

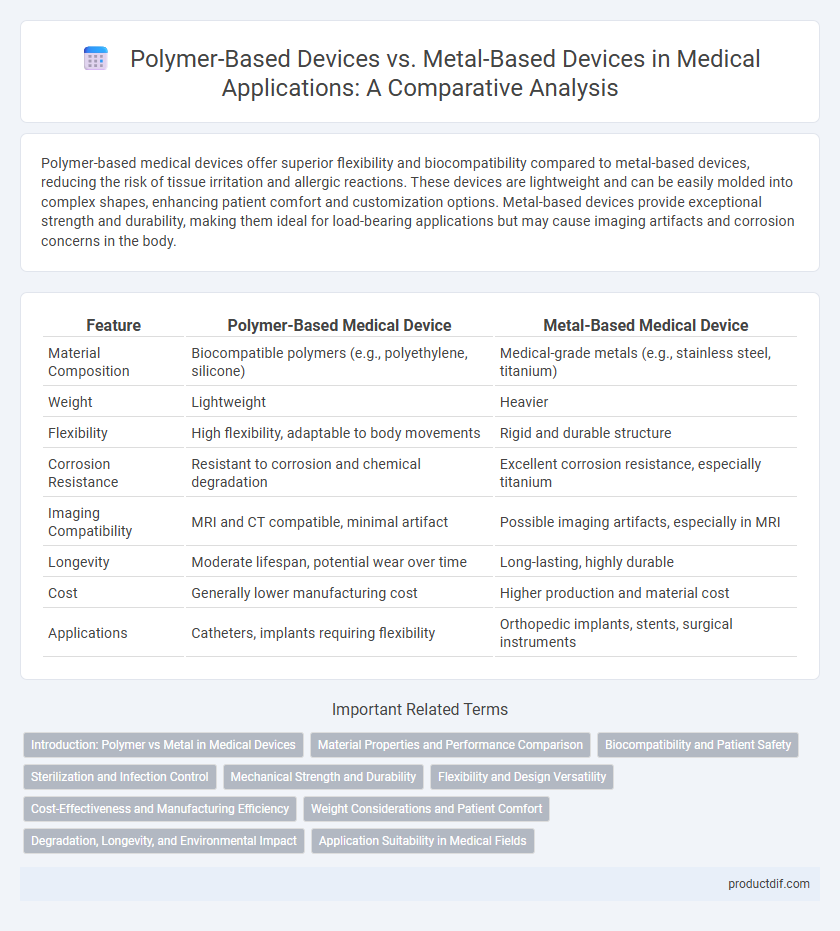

Table of Comparison

| Feature | Polymer-Based Medical Device | Metal-Based Medical Device |

|---|---|---|

| Material Composition | Biocompatible polymers (e.g., polyethylene, silicone) | Medical-grade metals (e.g., stainless steel, titanium) |

| Weight | Lightweight | Heavier |

| Flexibility | High flexibility, adaptable to body movements | Rigid and durable structure |

| Corrosion Resistance | Resistant to corrosion and chemical degradation | Excellent corrosion resistance, especially titanium |

| Imaging Compatibility | MRI and CT compatible, minimal artifact | Possible imaging artifacts, especially in MRI |

| Longevity | Moderate lifespan, potential wear over time | Long-lasting, highly durable |

| Cost | Generally lower manufacturing cost | Higher production and material cost |

| Applications | Catheters, implants requiring flexibility | Orthopedic implants, stents, surgical instruments |

Introduction: Polymer vs Metal in Medical Devices

Polymer-based medical devices offer enhanced flexibility, biocompatibility, and corrosion resistance compared to metal-based alternatives, making them suitable for soft tissue applications and long-term implants. Metal-based devices provide superior mechanical strength, durability, and electrical conductivity, essential for load-bearing implants and devices requiring precise structural integrity. The choice between polymer and metal materials directly impacts device performance, patient outcomes, and manufacturing processes in medical technology development.

Material Properties and Performance Comparison

Polymer-based medical devices offer superior flexibility, lower weight, and enhanced biocompatibility compared to metal-based devices, making them ideal for applications requiring minimal tissue irritation and adaptability to complex anatomical structures. Metal-based devices provide greater mechanical strength, durability, and resistance to wear and corrosion, suitable for load-bearing implants and long-term structural support. Performance differences include polymers exhibiting lower modulus of elasticity, which reduces stress shielding, whereas metals ensure higher fatigue resistance and load-bearing capacity in critical medical applications.

Biocompatibility and Patient Safety

Polymer-based medical devices exhibit superior biocompatibility compared to metal-based devices due to their reduced risk of corrosion and leaching of toxic ions, minimizing inflammatory responses and tissue irritation. Polymers also offer enhanced flexibility and customization, which improves patient comfort and reduces complications related to implant rigidity. Metal-based devices, while providing structural strength, often present challenges such as metal hypersensitivity and potential for long-term ion release, impacting patient safety in susceptible individuals.

Sterilization and Infection Control

Polymer-based medical devices exhibit superior resistance to common sterilization methods such as gamma radiation and ethylene oxide, maintaining structural integrity and reducing the risk of microbial contamination. Metal-based devices, while durable, often require high-temperature autoclaving that can compromise device surfaces and increase susceptibility to biofilm formation. Advances in polymer coatings and antimicrobial additives enhance infection control by inhibiting bacterial adhesion and promoting sterilant penetration compared to traditional metal implants.

Mechanical Strength and Durability

Polymer-based medical devices offer enhanced flexibility and biocompatibility, making them suitable for applications requiring adaptability to dynamic biological environments. Metal-based devices, such as those made from titanium or stainless steel, provide superior mechanical strength and long-term durability, essential for load-bearing implants and structural support. The choice between polymer and metal devices depends on the specific mechanical demands and lifespan requirements of the medical application.

Flexibility and Design Versatility

Polymer-based medical devices offer superior flexibility and design versatility compared to metal-based devices due to their ability to be easily molded into complex shapes and customized for specific applications. Their inherent elasticity allows for improved patient comfort and adaptability to dynamic anatomical movements, which is critical in cardiovascular and orthopedic implants. Metal-based devices, while durable and strong, often lack the nuanced flexibility required for delicate or highly personalized medical interventions.

Cost-Effectiveness and Manufacturing Efficiency

Polymer-based medical devices offer significant cost-effectiveness due to lower material expenses and simplified manufacturing processes compared to metal-based devices, which typically require energy-intensive machining and finishing techniques. The versatility of polymers enables rapid prototyping and scalable production using injection molding, resulting in shorter lead times and reduced labor costs. Metal-based devices, while durable and biocompatible, often incur higher production costs and extended manufacturing cycles, impacting overall efficiency in large-scale medical device fabrication.

Weight Considerations and Patient Comfort

Polymer-based medical devices offer significant weight advantages over metal-based counterparts, contributing to enhanced patient comfort and reduced strain during prolonged use. The lower density of polymers decreases the overall device mass, facilitating easier handling and improved wearability. In contrast, metal-based devices, while durable, often result in increased device weight that can lead to discomfort and limited mobility for patients.

Degradation, Longevity, and Environmental Impact

Polymer-based medical devices generally exhibit controlled degradation rates, allowing for tailored resorption and reduced long-term environmental waste compared to metal-based devices, which are non-degradable and require surgical removal. Metal-based devices such as titanium implants offer superior longevity and mechanical strength but pose challenges related to corrosion, potential metal ion release, and environmental persistence. Biodegradable polymers minimize ecological impact through natural breakdown, whereas metal devices contribute to long-term environmental accumulation and recycling complexities.

Application Suitability in Medical Fields

Polymer-based medical devices offer superior biocompatibility and flexibility, making them ideal for applications such as implants, catheters, and wound dressings where patient comfort and tissue integration are critical. Metal-based devices provide enhanced strength, durability, and imaging compatibility, making them suitable for orthopedic implants, cardiovascular stents, and surgical instruments requiring high mechanical performance. Selection between polymer and metal devices depends on the specific clinical requirements, including load-bearing capacity, corrosion resistance, and long-term biostability.

Polymer-based device vs Metal-based device Infographic

productdif.com

productdif.com