Tantalum capacitors offer higher capacitance per volume and superior stability in low-voltage applications compared to ceramic capacitors. Ceramic capacitors exhibit better high-frequency performance and lower equivalent series resistance (ESR), making them ideal for decoupling and filtering in high-speed circuits. Choosing between tantalum and ceramic capacitors depends on factors like capacitance requirements, voltage rating, frequency response, and environmental stability.

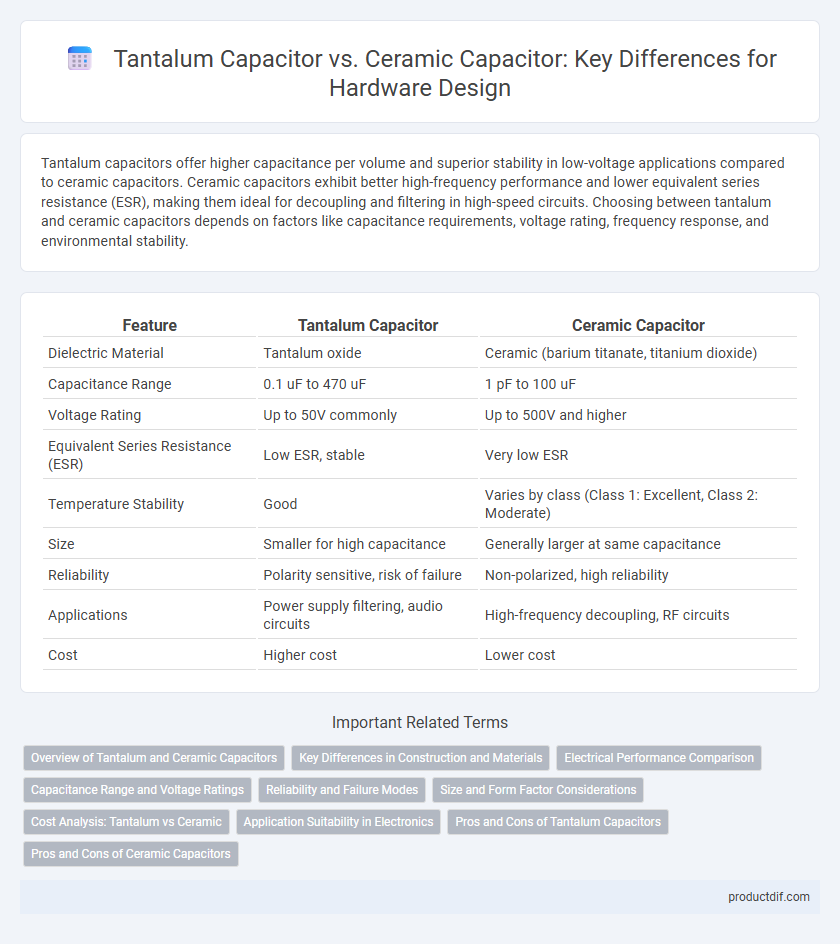

Table of Comparison

| Feature | Tantalum Capacitor | Ceramic Capacitor |

|---|---|---|

| Dielectric Material | Tantalum oxide | Ceramic (barium titanate, titanium dioxide) |

| Capacitance Range | 0.1 uF to 470 uF | 1 pF to 100 uF |

| Voltage Rating | Up to 50V commonly | Up to 500V and higher |

| Equivalent Series Resistance (ESR) | Low ESR, stable | Very low ESR |

| Temperature Stability | Good | Varies by class (Class 1: Excellent, Class 2: Moderate) |

| Size | Smaller for high capacitance | Generally larger at same capacitance |

| Reliability | Polarity sensitive, risk of failure | Non-polarized, high reliability |

| Applications | Power supply filtering, audio circuits | High-frequency decoupling, RF circuits |

| Cost | Higher cost | Lower cost |

Overview of Tantalum and Ceramic Capacitors

Tantalum capacitors offer high capacitance per volume and stable electrical performance, making them suitable for space-constrained applications requiring reliable and low ESR (Equivalent Series Resistance) characteristics. Ceramic capacitors provide excellent frequency response and low inductance, ideal for high-frequency filters and decoupling in electronic circuits. Both capacitor types differ significantly in dielectric materials, with tantalum using electrochemical anodized tantalum and ceramic employing multi-layered ceramic dielectrics, influencing their thermal stability and voltage ratings.

Key Differences in Construction and Materials

Tantalum capacitors feature a solid manganese dioxide or polymer electrolyte anode and a tantalum pentoxide dielectric, offering stable capacitance and high volumetric efficiency, while ceramic capacitors use a ceramic dielectric composed of materials like barium titanate and metal electrodes laminated in multiple layers. The solid electrolyte in tantalum capacitors provides low ESR, making them suitable for filtering and power supply applications, whereas ceramic capacitors' multilayer ceramic construction delivers low inductance and high-frequency performance. Tantalum capacitors typically have a polarized design due to their electrolytic nature, contrasting with the non-polarized form factor of ceramic capacitors, which enhances their versatility in AC signal circuits.

Electrical Performance Comparison

Tantalum capacitors exhibit higher capacitance per volume and superior stability with low Equivalent Series Resistance (ESR), making them suitable for applications requiring consistent electrical performance under varying temperatures and frequencies. Ceramic capacitors offer excellent high-frequency characteristics with low losses and higher voltage ratings, but they may suffer from capacitance degradation under DC bias and temperature variations. The choice between tantalum and ceramic capacitors depends on the trade-off between stability, size, voltage rating, and frequency response in specific electronic circuit designs.

Capacitance Range and Voltage Ratings

Tantalum capacitors typically offer capacitance values ranging from 0.1 uF to 470 uF with voltage ratings between 4V and 50V, making them suitable for applications requiring stable capacitance in small volumes. Ceramic capacitors provide a broader capacitance range from a few picofarads up to 100 uF and voltage ratings extending from 6.3V to over 100V, ideal for high-frequency and decoupling applications. The choice between tantalum and ceramic capacitors depends on the required capacitance density and voltage tolerance within the circuit design.

Reliability and Failure Modes

Tantalum capacitors offer high volumetric efficiency and stable capacitance but are prone to catastrophic failure due to dielectric breakdown when subjected to high surge currents or voltage spikes. Ceramic capacitors exhibit excellent reliability with low equivalent series resistance (ESR) and minimal failure modes, primarily cracking under mechanical stress or thermal cycling. In mission-critical hardware, ceramic capacitors are preferred for their robustness, whereas tantalum capacitors require careful derating to mitigate the risk of short-circuit failures.

Size and Form Factor Considerations

Tantalum capacitors offer higher volumetric efficiency, providing larger capacitance values in a smaller package compared to ceramic capacitors, making them ideal for space-constrained applications. Ceramic capacitors are available in smaller, flexible form factors with multilayer designs that support high-frequency performance but often require larger sizes to achieve equivalent capacitance. Selecting between tantalum and ceramic capacitors depends on the specific size limitations and electrical requirements of the hardware design.

Cost Analysis: Tantalum vs Ceramic

Tantalum capacitors generally exhibit higher costs due to their complex manufacturing processes and superior volumetric efficiency, making them ideal for space-constrained applications. Ceramic capacitors, benefiting from mass production and simpler composition, offer a cost-effective solution for high-frequency and high-voltage applications, especially when capacitance requirements are moderate. Cost analysis must consider not only unit price but also performance trade-offs such as stability, reliability, and lifespan within specific hardware designs.

Application Suitability in Electronics

Tantalum capacitors offer high capacitance stability and are ideal for space-constrained, low-voltage power supply circuits, particularly in audio and RF applications due to their low equivalent series resistance (ESR). Ceramic capacitors provide excellent high-frequency performance and are commonly used for decoupling and filtering in microcontroller circuits and high-speed data lines. Selecting between tantalum and ceramic capacitors depends on the application's voltage requirements, frequency response, and size constraints.

Pros and Cons of Tantalum Capacitors

Tantalum capacitors offer high capacitance per volume and excellent stability with low equivalent series resistance (ESR), making them ideal for applications requiring reliable performance in compact spaces. Their drawbacks include susceptibility to failure due to voltage spikes and polarity sensitivity, necessitating careful circuit design to avoid damage. Compared to ceramic capacitors, tantalum types provide superior capacitance density but at a higher cost and with stricter handling requirements.

Pros and Cons of Ceramic Capacitors

Ceramic capacitors offer high stability, low ESR (Equivalent Series Resistance), and excellent frequency characteristics, making them ideal for high-frequency applications and noise filtering. They are compact, cost-effective, and exhibit great reliability under varying temperature and voltage ranges, but can suffer from microphonic effects and limited capacitance values compared to tantalum capacitors. Ceramic capacitors also show reduced performance in high-voltage and high-capacitance scenarios due to their physical size constraints and material properties.

Tantalum capacitor vs Ceramic capacitor Infographic

productdif.com

productdif.com