Annealed glassware pet offers a standard level of strength and clarity but is more prone to breakage under impact or thermal stress. Toughened glassware pet undergoes a rigorous heat treatment process, resulting in enhanced durability, resistance to shattering, and improved safety in case of breakage. Choosing toughened glassware pet ensures better performance in demanding environments, minimizing the risk of damage and injury.

Table of Comparison

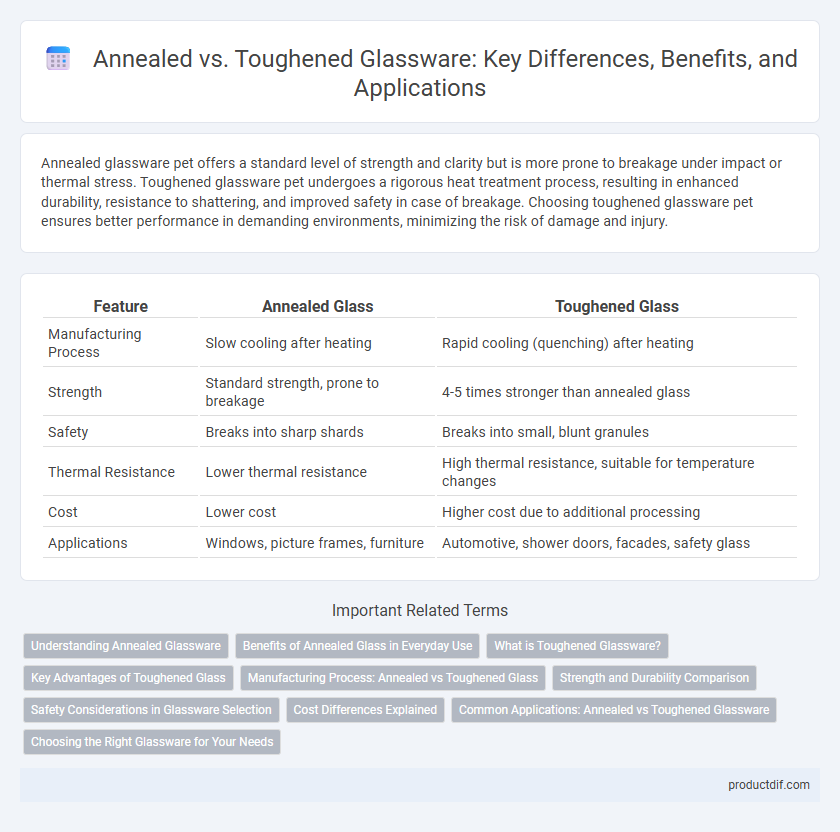

| Feature | Annealed Glass | Toughened Glass |

|---|---|---|

| Manufacturing Process | Slow cooling after heating | Rapid cooling (quenching) after heating |

| Strength | Standard strength, prone to breakage | 4-5 times stronger than annealed glass |

| Safety | Breaks into sharp shards | Breaks into small, blunt granules |

| Thermal Resistance | Lower thermal resistance | High thermal resistance, suitable for temperature changes |

| Cost | Lower cost | Higher cost due to additional processing |

| Applications | Windows, picture frames, furniture | Automotive, shower doors, facades, safety glass |

Understanding Annealed Glassware

Annealed glassware undergoes a slow cooling process to relieve internal stresses, resulting in a stable and uniform material ideal for everyday use and laboratory settings. This type of glass is less resistant to impact and thermal shock compared to toughened glass but offers excellent clarity and workability. Understanding annealed glassware is essential for selecting appropriate glass types where flexibility and ease of shaping are prioritized over high strength.

Benefits of Annealed Glass in Everyday Use

Annealed glass offers excellent clarity and smooth edges, making it ideal for everyday applications such as windows, picture frames, and furniture where safety glass is not mandatory. Its ease of cutting and shaping provides versatility in design and installation, reducing fabrication costs. Unlike toughened glass, annealed glass can be repaired if damaged, extending the lifespan of products incorporating it.

What is Toughened Glassware?

Toughened glassware is heat-treated to increase its strength and thermal resistance compared to annealed glass, making it less likely to break under mechanical stress or sudden temperature changes. This process involves heating the glass to around 620degC and then rapidly cooling it, creating compressive stresses on the surface and tensile stresses inside. As a result, toughened glassware is widely used in applications requiring enhanced durability and safety, such as laboratory equipment and kitchenware.

Key Advantages of Toughened Glass

Toughened glass offers superior strength, being up to five times stronger than annealed glass, which enhances safety by reducing the risk of breakage under impact or thermal stress. Its safety feature ensures that if broken, it shatters into small, blunt pieces instead of sharp shards, minimizing injury. Toughened glass also provides better thermal resistance and durability, making it ideal for use in architectural applications, automotive windows, and tempered glass furniture.

Manufacturing Process: Annealed vs Toughened Glass

Annealed glass undergoes a slow cooling process after being heated to remove internal stresses, resulting in a more flexible but less durable product. Toughened glass is rapidly cooled through quenching, creating a state of compression on the surface that significantly increases its strength and resistance to impact. The manufacturing process difference directly impacts the glass's safety features, with toughened glass shattering into small, blunt pieces, unlike annealed glass which breaks into sharp shards.

Strength and Durability Comparison

Toughened glass offers superior strength and durability compared to annealed glass, being up to five times stronger due to its thermal treatment process. Annealed glass, cooled slowly during manufacturing, is more prone to breakage under impact and thermal stress. Toughened glass also shards into small, less dangerous pieces upon breakage, enhancing safety in applications requiring high resilience.

Safety Considerations in Glassware Selection

Annealed glass breaks into sharp, dangerous shards upon impact, posing significant safety hazards in environments requiring impact resistance. Toughened glass undergoes a thermal tempering process that increases its strength and causes it to shatter into small, blunt granules, reducing injury risks. Selecting toughened glass for applications such as doors, windows, and protective screens enhances safety by minimizing potential harm from breakage.

Cost Differences Explained

Annealed glass is typically more cost-effective due to its simpler manufacturing process and lower production energy requirements compared to toughened glass. Toughened glass undergoes a specialized tempering process that increases strength and safety but significantly raises costs, often doubling the price of annealed glass. The added expense of toughened glass is justified in applications requiring higher durability and impact resistance, such as automotive windows and architectural safety panels.

Common Applications: Annealed vs Toughened Glassware

Annealed glassware is commonly used in laboratory settings, windows, and picture frames where moderate strength and easy cutting or shaping are required. Toughened glassware finds applications in automotive windows, shower doors, and safety glass products due to its higher impact resistance and shatterproof qualities. Industries prioritize toughened glassware in environments demanding enhanced durability and safety compliance standards.

Choosing the Right Glassware for Your Needs

Choosing the right glassware depends on understanding the differences between annealed and toughened glass; annealed glass is slowly cooled to relieve internal stresses, making it more prone to breakage under impact but easier to cut and shape. Toughened glass undergoes rapid cooling that increases its strength and causes it to shatter into small granules upon breakage, enhancing safety in high-impact environments. Selecting toughened glass is ideal for applications requiring enhanced durability and safety, while annealed glass suits situations where customization and cost-effectiveness are priorities.

Annealed vs Toughened Infographic

productdif.com

productdif.com