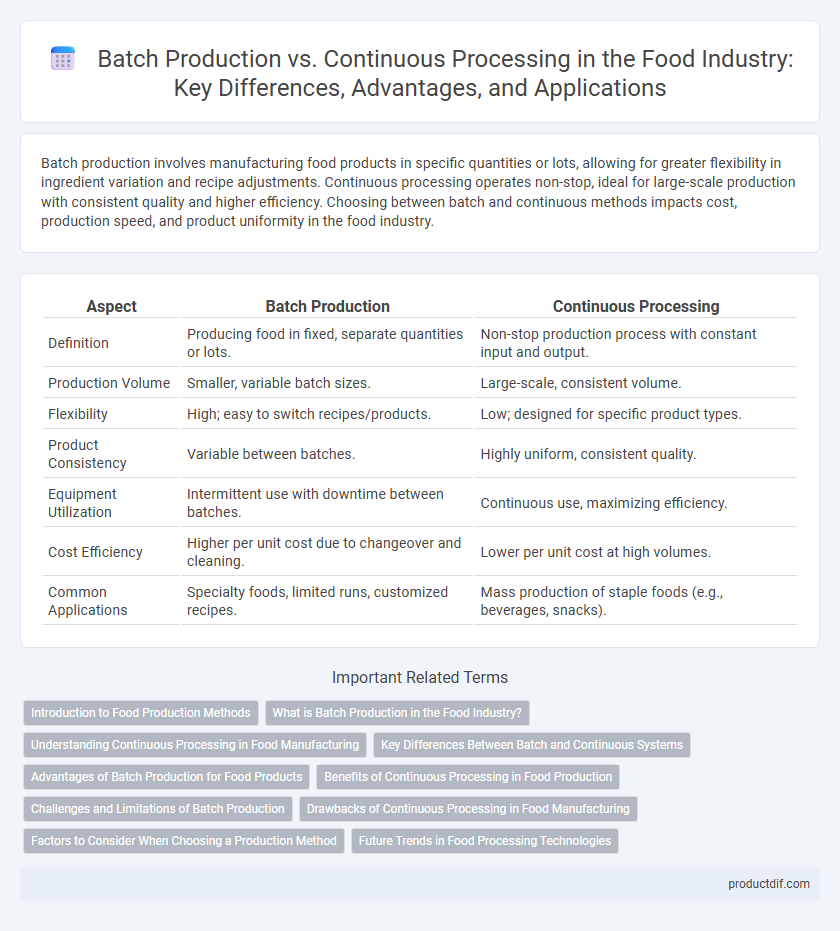

Batch production involves manufacturing food products in specific quantities or lots, allowing for greater flexibility in ingredient variation and recipe adjustments. Continuous processing operates non-stop, ideal for large-scale production with consistent quality and higher efficiency. Choosing between batch and continuous methods impacts cost, production speed, and product uniformity in the food industry.

Table of Comparison

| Aspect | Batch Production | Continuous Processing |

|---|---|---|

| Definition | Producing food in fixed, separate quantities or lots. | Non-stop production process with constant input and output. |

| Production Volume | Smaller, variable batch sizes. | Large-scale, consistent volume. |

| Flexibility | High; easy to switch recipes/products. | Low; designed for specific product types. |

| Product Consistency | Variable between batches. | Highly uniform, consistent quality. |

| Equipment Utilization | Intermittent use with downtime between batches. | Continuous use, maximizing efficiency. |

| Cost Efficiency | Higher per unit cost due to changeover and cleaning. | Lower per unit cost at high volumes. |

| Common Applications | Specialty foods, limited runs, customized recipes. | Mass production of staple foods (e.g., beverages, snacks). |

Introduction to Food Production Methods

Batch production in food manufacturing involves producing goods in specific quantities or lots, allowing for flexibility in product variation and easy quality control. Continuous processing maintains a constant flow of raw materials through the system, optimizing efficiency and consistency for large-scale food products like beverages and snacks. Choosing between batch and continuous methods depends on factors such as production volume, product type, and cost efficiency.

What is Batch Production in the Food Industry?

Batch production in the food industry involves manufacturing food products in specific, controlled quantities or lots, allowing for flexibility in recipe variations and quality control. This method is ideal for artisanal foods, seasonal items, and specialty products where precise portioning and customization are critical. Batch production enables efficient management of ingredients and reduces waste by producing only the required amount in each cycle.

Understanding Continuous Processing in Food Manufacturing

Continuous processing in food manufacturing involves the nonstop production of food products, allowing for consistent quality and higher throughput. This method utilizes automated systems to monitor and control variables such as temperature, pressure, and ingredient flow, minimizing waste and increasing efficiency. Compared to batch production, continuous processing reduces downtime and is ideal for large-scale operations requiring uniformity and rapid output.

Key Differences Between Batch and Continuous Systems

Batch production involves processing food in distinct, separate quantities, allowing precise control over small-scale or customized products, while continuous processing operates nonstop, enhancing efficiency and consistency for large-volume manufacturing. Batch systems offer flexibility to adjust recipes and troubleshoot between batches, whereas continuous systems require stable formulations to maintain steady flow and uniform quality. Equipment complexity and capital investment are typically higher in continuous processing due to automation and integration demands, but yield higher throughput compared to batch production's lower output but greater versatility.

Advantages of Batch Production for Food Products

Batch production in food manufacturing enables greater flexibility in producing diverse product varieties and allows easy adjustments in recipes to meet changing consumer preferences. It ensures higher quality control and consistency by isolating defects within individual batches, minimizing the risk of widespread contamination. Smaller batch sizes also reduce equipment downtime and facilitate efficient testing of new formulations or seasonal offerings.

Benefits of Continuous Processing in Food Production

Continuous processing in food production enhances efficiency by enabling nonstop operations that reduce downtime and maximize throughput. It maintains consistent product quality through automated controls and real-time monitoring, minimizing variability and waste. This method also offers better scalability for large-scale food manufacturers aiming to meet increasing demand while lowering production costs.

Challenges and Limitations of Batch Production

Batch production in food manufacturing faces challenges such as inconsistent product quality due to variations between batches, leading to difficulties in scaling operations efficiently. It often results in higher labor costs and longer downtime for equipment cleaning and setup between batches, impacting overall production efficiency. Limited flexibility and slower response to market demand changes further restrict batch production compared to continuous processing.

Drawbacks of Continuous Processing in Food Manufacturing

Continuous processing in food manufacturing often faces challenges such as limited flexibility in product variation and difficulty in handling batch-specific adjustments, impacting customization and innovation. Equipment downtime can lead to significant production losses, as the entire process is interconnected and halting one segment disrupts the whole line. Additionally, maintaining consistent quality control is complex due to the high-speed, nonstop operation, increasing the risk of undetected defects and contamination.

Factors to Consider When Choosing a Production Method

Batch production allows flexibility for producing varied food products with different recipes, ideal for small to medium volumes and seasonal items. Continuous processing suits large-scale, standardized food manufacturing with consistent quality and efficiency, minimizing downtime. Key factors to consider include production volume, product customization, equipment cost, and process control requirements.

Future Trends in Food Processing Technologies

Future trends in food processing technologies emphasize the integration of continuous processing systems to enhance efficiency, product consistency, and sustainability compared to traditional batch production. Advances in automation, real-time monitoring, and AI-driven process control enable continuous processing to reduce energy consumption, minimize waste, and improve food safety standards. Emerging technologies such as membrane filtration, high-pressure processing, and 3D food printing are transforming continuous production lines, supporting scalability and customization in the evolving food industry.

Batch Production vs Continuous Processing Infographic

productdif.com

productdif.com