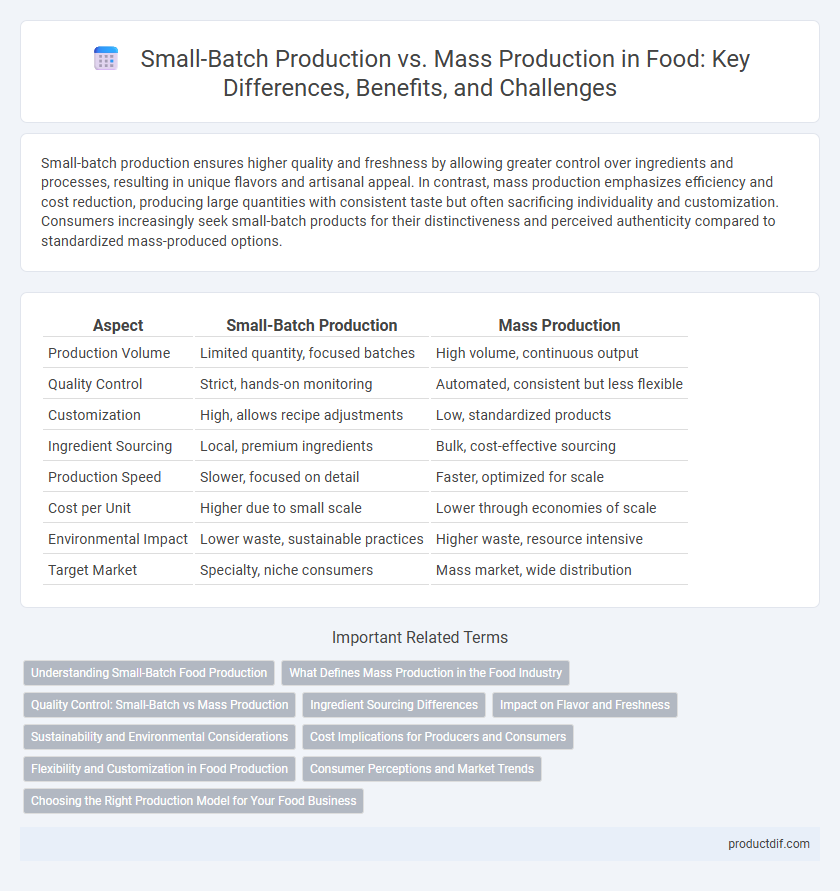

Small-batch production ensures higher quality and freshness by allowing greater control over ingredients and processes, resulting in unique flavors and artisanal appeal. In contrast, mass production emphasizes efficiency and cost reduction, producing large quantities with consistent taste but often sacrificing individuality and customization. Consumers increasingly seek small-batch products for their distinctiveness and perceived authenticity compared to standardized mass-produced options.

Table of Comparison

| Aspect | Small-Batch Production | Mass Production |

|---|---|---|

| Production Volume | Limited quantity, focused batches | High volume, continuous output |

| Quality Control | Strict, hands-on monitoring | Automated, consistent but less flexible |

| Customization | High, allows recipe adjustments | Low, standardized products |

| Ingredient Sourcing | Local, premium ingredients | Bulk, cost-effective sourcing |

| Production Speed | Slower, focused on detail | Faster, optimized for scale |

| Cost per Unit | Higher due to small scale | Lower through economies of scale |

| Environmental Impact | Lower waste, sustainable practices | Higher waste, resource intensive |

| Target Market | Specialty, niche consumers | Mass market, wide distribution |

Understanding Small-Batch Food Production

Small-batch food production emphasizes artisanal quality, freshness, and control over ingredients, making it ideal for specialty products and local markets. This method allows producers to experiment with unique recipes and maintain higher standards in hygiene and flavor consistency. Unlike mass production, small-batch processes reduce waste and support sustainable sourcing, aligning with consumer demand for authenticity and traceability.

What Defines Mass Production in the Food Industry

Mass production in the food industry is defined by the large-scale manufacturing of products using standardized processes and automated machinery to achieve high output and consistent quality. This approach emphasizes economies of scale, reducing costs per unit by producing vast quantities of identical food items. Key characteristics include streamlined assembly lines, rigorous quality control, and extensive distribution networks to supply broad markets efficiently.

Quality Control: Small-Batch vs Mass Production

Small-batch production allows for meticulous quality control by enabling close monitoring of each product, resulting in consistent flavor and texture. Mass production relies heavily on automated processes and statistical quality control techniques to maintain uniformity across large volumes, but may sacrifice the nuanced quality found in smaller batches. Each approach balances production scale with different levels of precision in ingredient sourcing, handling, and final inspection.

Ingredient Sourcing Differences

Small-batch production prioritizes sourcing high-quality, often local, and organic ingredients to ensure freshness and unique flavor profiles, emphasizing traceability and sustainability. In contrast, mass production relies on bulk purchasing from large-scale suppliers, focusing on cost efficiency and supply chain consistency over ingredient variety or provenance. This difference significantly impacts the quality, taste, and environmental footprint of the final food products.

Impact on Flavor and Freshness

Small-batch production preserves flavor and freshness by allowing more control over ingredient quality and cooking times, resulting in richer, more vibrant taste profiles. Mass production often sacrifices these qualities due to large-scale processing and extended storage, leading to diluted flavors and reduced freshness. Consumers seeking authentic, flavorful food typically prefer small-batch products for their superior taste and higher nutritional value.

Sustainability and Environmental Considerations

Small-batch production minimizes waste and energy use by focusing on quality control and local sourcing, reducing the carbon footprint compared to mass production. Mass production often relies on large-scale machinery and transportation, leading to higher greenhouse gas emissions and resource depletion. Sustainable food systems increasingly favor small-batch methods to promote environmental stewardship and reduce industrial agriculture's ecological impact.

Cost Implications for Producers and Consumers

Small-batch production often leads to higher per-unit costs due to limited economies of scale and increased labor intensity, impacting both producers and consumers with premium pricing. Mass production benefits from streamlined processes and bulk purchasing, significantly lowering costs and retail prices. Producers must balance quality with volume, while consumers weigh affordability against product uniqueness and freshness.

Flexibility and Customization in Food Production

Small-batch production in food manufacturing allows for greater flexibility and customization, enabling producers to adapt recipes and ingredients quickly to meet niche market demands or dietary restrictions. In contrast, mass production prioritizes efficiency and volume, often limiting the ability to tailor products to specific consumer preferences. This flexibility in small-batch production supports innovation and premium product development, fostering unique flavors and high-quality artisanal goods.

Consumer Perceptions and Market Trends

Small-batch food production is increasingly favored by consumers seeking artisanal quality, unique flavors, and perceived freshness compared to mass production's uniformity and cost-efficiency. Market trends indicate a growing demand for sustainably sourced ingredients and transparency, driving brands to emphasize small-scale, local sourcing to build trust and loyalty. Consumer perceptions associate small-batch products with higher nutritional value and ethical practices, influencing premium pricing and niche market expansion.

Choosing the Right Production Model for Your Food Business

Small-batch production emphasizes quality control, artisanal techniques, and unique flavors, making it ideal for niche markets and gourmet food brands seeking differentiation. Mass production excels in efficiency, cost reduction, and large-scale distribution, suitable for businesses aiming to meet high demand and competitive pricing. Selecting the right production model depends on your target audience, product complexity, and long-term scalability goals in the food industry.

Small-batch production vs Mass production Infographic

productdif.com

productdif.com