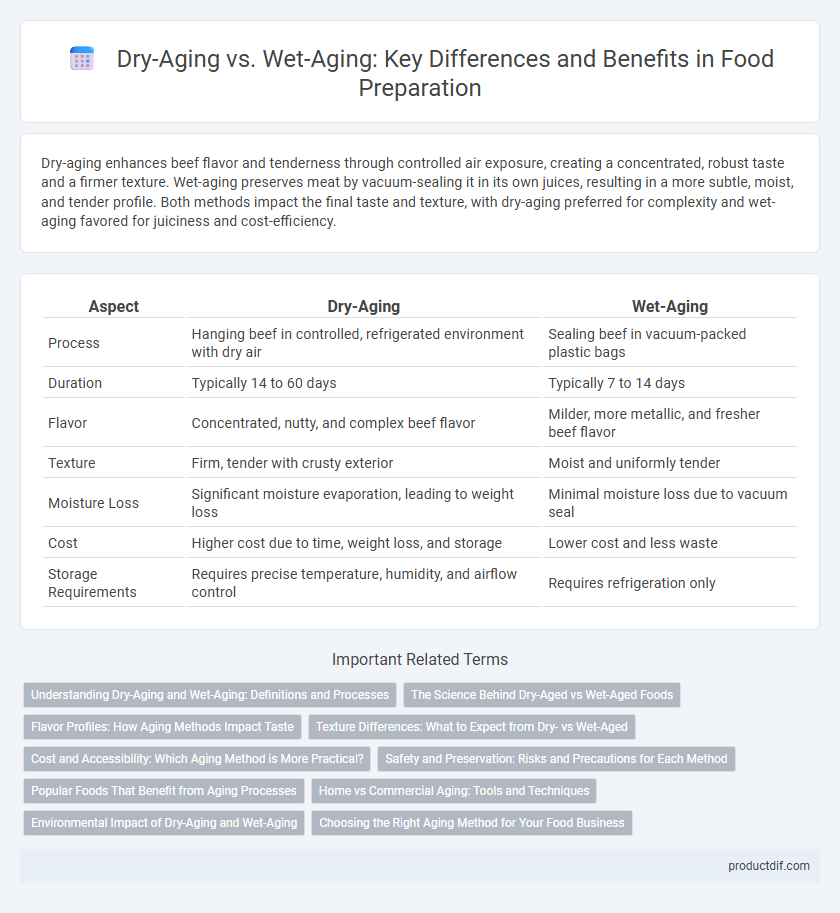

Dry-aging enhances beef flavor and tenderness through controlled air exposure, creating a concentrated, robust taste and a firmer texture. Wet-aging preserves meat by vacuum-sealing it in its own juices, resulting in a more subtle, moist, and tender profile. Both methods impact the final taste and texture, with dry-aging preferred for complexity and wet-aging favored for juiciness and cost-efficiency.

Table of Comparison

| Aspect | Dry-Aging | Wet-Aging |

|---|---|---|

| Process | Hanging beef in controlled, refrigerated environment with dry air | Sealing beef in vacuum-packed plastic bags |

| Duration | Typically 14 to 60 days | Typically 7 to 14 days |

| Flavor | Concentrated, nutty, and complex beef flavor | Milder, more metallic, and fresher beef flavor |

| Texture | Firm, tender with crusty exterior | Moist and uniformly tender |

| Moisture Loss | Significant moisture evaporation, leading to weight loss | Minimal moisture loss due to vacuum seal |

| Cost | Higher cost due to time, weight loss, and storage | Lower cost and less waste |

| Storage Requirements | Requires precise temperature, humidity, and airflow control | Requires refrigeration only |

Understanding Dry-Aging and Wet-Aging: Definitions and Processes

Dry-aging beef involves hanging the meat in a controlled, refrigerated environment with precise temperature and humidity levels, allowing natural enzymes to break down muscle fibers and develop concentrated flavors over several weeks. Wet-aging, on the other hand, entails vacuum-sealing the meat in plastic packaging to retain moisture while aging in its own juices, resulting in a more tender texture without the intense flavor profile of dry-aged beef. Both methods rely on enzymatic and biochemical processes to enhance tenderness, but dry-aging produces a distinct, nutty flavor and firmer texture compared to the juicier, milder wet-aged meat.

The Science Behind Dry-Aged vs Wet-Aged Foods

Dry-aging involves storing meat in a controlled, refrigerated environment with precise temperature and humidity to promote enzymatic breakdown of muscle fibers, enhancing tenderness and flavor through moisture evaporation and natural enzymatic activity. Wet-aging, by contrast, seals meat in vacuum-packed bags to retain moisture, allowing proteolytic enzymes to tenderize the meat without flavor concentration caused by dehydration. The difference in biochemical processes results in dry-aged meat having a more intense, nutty flavor and firmer texture, while wet-aged meat remains juicier with a milder taste.

Flavor Profiles: How Aging Methods Impact Taste

Dry-aging intensifies flavor by allowing natural enzymes to break down muscle tissue while exposed to controlled air, resulting in a bold, nutty, and concentrated beef taste. Wet-aging involves vacuum-sealing meat in its own juices, producing a more subtle, tender, and slightly metallic flavor due to anaerobic enzymatic activity. The choice between dry-aging and wet-aging significantly affects meat's umami depth, texture, and overall palatability, influencing culinary applications and consumer preferences.

Texture Differences: What to Expect from Dry- vs Wet-Aged

Dry-aging intensifies beef's texture by allowing natural enzymes to break down muscle fibers, resulting in a firmer, more concentrated chew with a distinctive crust. Wet-aging preserves moisture within vacuum-sealed packaging, producing a tender, juicier texture due to enzymatic activity without moisture loss. Consumers opting for dry-aged beef experience a robust, denser mouthfeel while wet-aged cuts offer a softer, more succulent bite.

Cost and Accessibility: Which Aging Method is More Practical?

Dry-aging typically incurs higher costs due to the need for specialized facilities, controlled environments, and longer aging periods that result in weight loss from moisture evaporation. Wet-aging is more cost-effective and accessible since it involves vacuum-sealed packaging and refrigeration, making it easier for most producers and retailers to implement without significant infrastructure investment. For consumers and businesses prioritizing practicality and affordability, wet-aging remains the more accessible aging method.

Safety and Preservation: Risks and Precautions for Each Method

Dry-aging beef involves exposing meat to controlled temperature and humidity to enhance flavor but carries a higher risk of surface contamination and spoilage if not properly managed. Wet-aging, where meat is vacuum-sealed and refrigerated, minimizes microbial exposure and spoilage but may retain more moisture, affecting texture and shelf-life. Proper temperature control, sanitation, and monitoring are critical in both methods to ensure food safety and prevent harmful bacterial growth during the aging process.

Popular Foods That Benefit from Aging Processes

Dry-aging enhances the flavor and tenderness of beef cuts like ribeye, strip loin, and brisket by allowing natural enzymes to break down muscle fibers while moisture evaporates, concentrating taste. Wet-aging, commonly used for tender cuts such as sirloin and filet mignon, involves vacuum-sealing meat to retain moisture and develop a more subtle, buttery flavor profile. Both aging methods are also applied to artisanal cheeses and cured sausages, where enzymatic activity and microbial growth improve texture and deepen complex flavors.

Home vs Commercial Aging: Tools and Techniques

Dry-aging requires a controlled environment with specific humidity and temperature levels, often achieved using specialized refrigerators with airflow systems, making it more suitable for commercial settings. Wet-aging involves sealing meat in vacuum-packed bags, which can be easily done at home with basic vacuum sealing equipment, offering a simpler alternative for home cooks. Commercial aging facilities invest in advanced monitoring tools to ensure consistent quality, while home methods rely on accessible tools like temperature-controlled fridges and vacuum sealers.

Environmental Impact of Dry-Aging and Wet-Aging

Dry-aging beef requires controlled airflow and specific temperature conditions, leading to higher energy consumption and increased environmental footprint compared to wet-aging, which uses vacuum-sealed packaging with minimal refrigeration energy. Wet-aging produces less food waste since the meat retains its moisture, whereas dry-aging results in noticeable trim loss due to dehydration and surface mold removal. The carbon emissions associated with dry-aging are consequently higher, as prolonged storage times and energy-intensive aging rooms contribute to increased greenhouse gas output.

Choosing the Right Aging Method for Your Food Business

Choosing the right aging method for your food business depends on factors such as desired flavor profile, cost efficiency, and storage capacity. Dry-aging enhances meat tenderness and imparts rich, nutty flavors by exposing it to controlled air in a refrigerated environment, typically requiring longer aging periods and specialized facilities. Wet-aging, performed by vacuum-sealing meat in plastic, retains moisture and reduces aging time, making it a cost-effective option for businesses prioritizing juiciness and quicker turnover.

Dry-aging vs Wet-aging Infographic

productdif.com

productdif.com