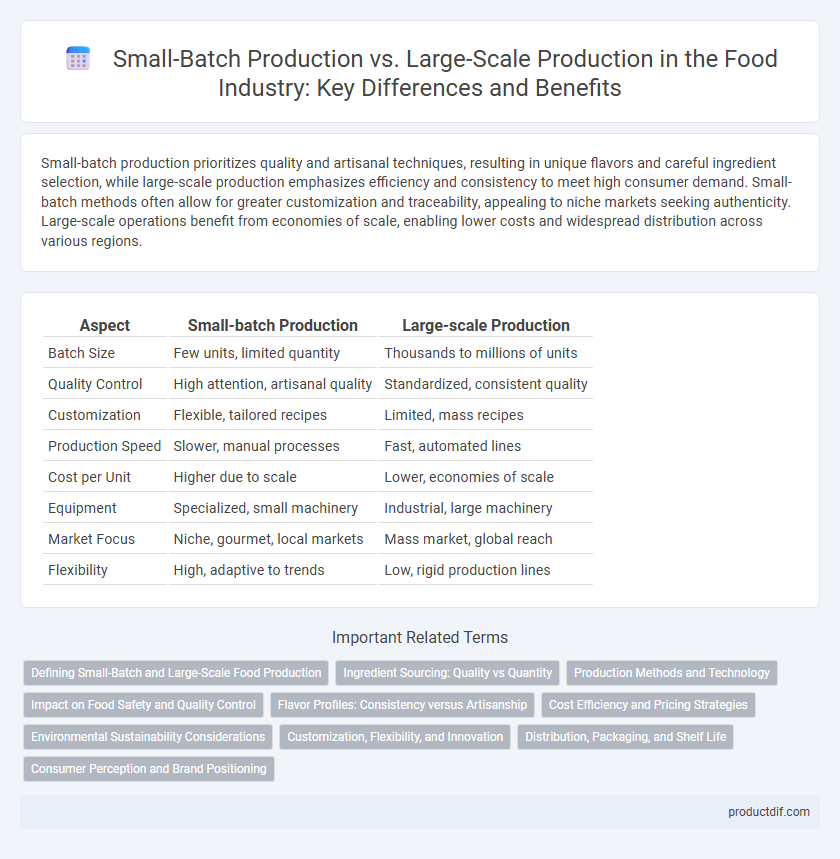

Small-batch production prioritizes quality and artisanal techniques, resulting in unique flavors and careful ingredient selection, while large-scale production emphasizes efficiency and consistency to meet high consumer demand. Small-batch methods often allow for greater customization and traceability, appealing to niche markets seeking authenticity. Large-scale operations benefit from economies of scale, enabling lower costs and widespread distribution across various regions.

Table of Comparison

| Aspect | Small-batch Production | Large-scale Production |

|---|---|---|

| Batch Size | Few units, limited quantity | Thousands to millions of units |

| Quality Control | High attention, artisanal quality | Standardized, consistent quality |

| Customization | Flexible, tailored recipes | Limited, mass recipes |

| Production Speed | Slower, manual processes | Fast, automated lines |

| Cost per Unit | Higher due to scale | Lower, economies of scale |

| Equipment | Specialized, small machinery | Industrial, large machinery |

| Market Focus | Niche, gourmet, local markets | Mass market, global reach |

| Flexibility | High, adaptive to trends | Low, rigid production lines |

Defining Small-Batch and Large-Scale Food Production

Small-batch food production involves creating limited quantities of products, emphasizing artisanal techniques and quality control to maintain unique flavors and freshness. Large-scale food production utilizes industrial processes and automated systems to manufacture vast volumes efficiently, ensuring consistent product availability and cost-effectiveness. Defining small-batch versus large-scale production highlights differences in production volume, customization, and scale of distribution within the food industry.

Ingredient Sourcing: Quality vs Quantity

Small-batch production prioritizes sourcing high-quality, often local or organic ingredients, ensuring superior flavor and freshness. Large-scale production emphasizes quantity, relying on bulk suppliers and standardized ingredients to maintain cost efficiency and consistent supply. This trade-off impacts the final product's taste, nutritional value, and consumer perception.

Production Methods and Technology

Small-batch production employs artisanal techniques and hands-on craftsmanship, often using traditional tools and methods to ensure quality and uniqueness in each batch. Large-scale production utilizes automated machinery and advanced technologies such as robotics and computerized systems to maximize efficiency, consistency, and output volume. The integration of Industry 4.0 technologies, including IoT sensors and data analytics, further optimizes large-scale production by enabling real-time monitoring and predictive maintenance.

Impact on Food Safety and Quality Control

Small-batch production allows for more precise monitoring of food safety and quality control due to limited batch sizes and hands-on management, reducing the risk of contamination and defects. Large-scale production relies heavily on automated systems and standardized protocols to maintain consistency but may face challenges in quickly identifying and addressing quality issues across extensive supply chains. Implementing rigorous testing and traceability measures is essential in both methods to ensure compliance with food safety regulations and protect consumer health.

Flavor Profiles: Consistency versus Artisanship

Small-batch production prioritizes rich, unique flavor profiles by allowing artisans to carefully control ingredients and cooking methods, resulting in distinct and often more complex tastes. Large-scale production emphasizes consistency and uniform flavor across batches, achieved through standardized processes and ingredient sourcing to meet consumer expectations at scale. While small-batch products appeal to niche markets seeking authenticity, large-scale products dominate mainstream markets with reliable and predictable flavors.

Cost Efficiency and Pricing Strategies

Small-batch production allows for greater flexibility in pricing strategies by targeting niche markets and emphasizing product uniqueness, though it typically incurs higher per-unit costs due to limited economies of scale. Large-scale production achieves significant cost efficiency through bulk purchasing of raw materials and automated processes, enabling competitive pricing but often limiting customization. Optimal pricing strategies balance these factors by leveraging large-scale cost savings while maintaining value perception in small-batch products to maximize profitability.

Environmental Sustainability Considerations

Small-batch production reduces environmental impact by minimizing waste, optimizing resource use, and supporting local supply chains, which lowers transportation emissions. Large-scale production often relies on extensive energy consumption and generates significant waste, contributing to higher carbon footprints and resource depletion. Emphasizing small-batch methods promotes sustainable agriculture practices and encourages biodiversity conservation, essential for long-term ecological balance.

Customization, Flexibility, and Innovation

Small-batch production enables greater customization and flexibility, allowing food producers to quickly adapt recipes and innovate with unique ingredients or packaging tailored to niche markets. Large-scale production, while efficient for mass distribution, often limits customization due to standardized processes and economies of scale. Emphasizing innovation is more feasible in small batches, fostering artisanal quality and rapid response to consumer trends compared to the rigid structure of large-scale operations.

Distribution, Packaging, and Shelf Life

Small-batch production offers greater flexibility in packaging customization and often uses artisanal materials that appeal to niche markets, enhancing brand identity and perceived quality. Large-scale production benefits from standardized packaging processes that optimize distribution efficiency and reduce costs through bulk shipments, supporting widespread retail availability. Shelf life in small-batch items may be shorter due to fewer preservatives and limited use of advanced packaging technologies, whereas large-scale products leverage extended shelf life with specialized sealing and preservatives to ensure freshness across longer supply chains.

Consumer Perception and Brand Positioning

Small-batch production is often perceived by consumers as a mark of artisanal quality and authenticity, fostering a strong emotional connection and brand loyalty. Large-scale production emphasizes consistency, affordability, and widespread availability, appealing to value-driven and convenience-oriented consumers. Brands leveraging small-batch techniques position themselves as premium and niche, while mass producers highlight scale efficiency and broad market reach.

Small-batch production vs Large-scale production Infographic

productdif.com

productdif.com