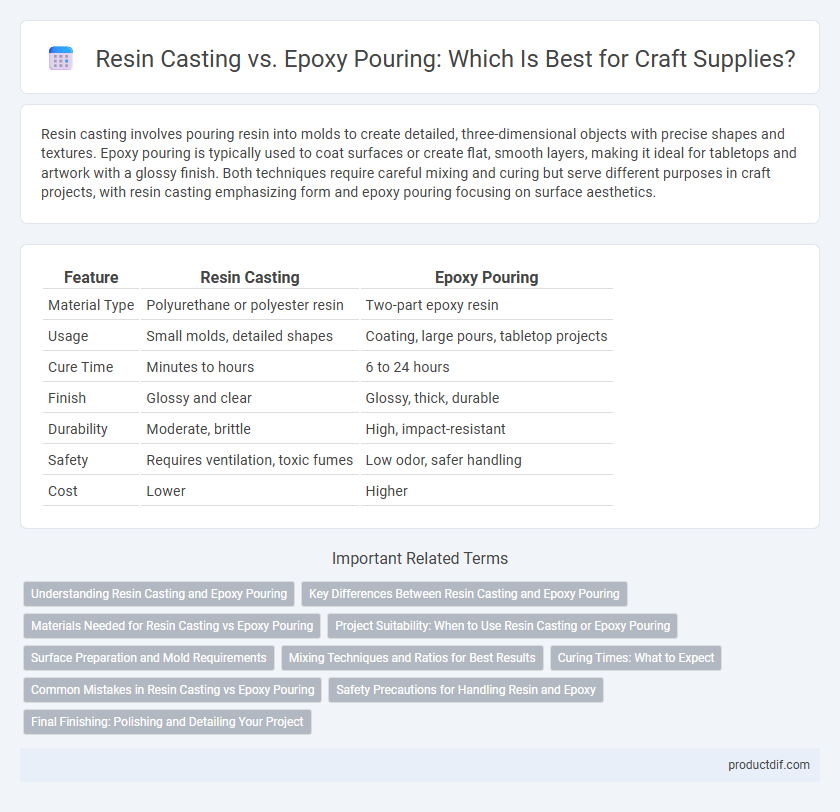

Resin casting involves pouring resin into molds to create detailed, three-dimensional objects with precise shapes and textures. Epoxy pouring is typically used to coat surfaces or create flat, smooth layers, making it ideal for tabletops and artwork with a glossy finish. Both techniques require careful mixing and curing but serve different purposes in craft projects, with resin casting emphasizing form and epoxy pouring focusing on surface aesthetics.

Table of Comparison

| Feature | Resin Casting | Epoxy Pouring |

|---|---|---|

| Material Type | Polyurethane or polyester resin | Two-part epoxy resin |

| Usage | Small molds, detailed shapes | Coating, large pours, tabletop projects |

| Cure Time | Minutes to hours | 6 to 24 hours |

| Finish | Glossy and clear | Glossy, thick, durable |

| Durability | Moderate, brittle | High, impact-resistant |

| Safety | Requires ventilation, toxic fumes | Low odor, safer handling |

| Cost | Lower | Higher |

Understanding Resin Casting and Epoxy Pouring

Resin casting involves pouring liquid resin into molds to create solid, detailed shapes, often using polyurethane or polyester resins for precise, durable results. Epoxy pouring uses epoxy resin poured into layers or molds, favored for its clarity, strong adhesion, and resistance to yellowing over time. Both techniques require careful mixing and curing but serve different crafting needs based on the project's complexity and desired finish.

Key Differences Between Resin Casting and Epoxy Pouring

Resin casting involves pouring resin into molds to create detailed, solid shapes, while epoxy pouring typically refers to spreading epoxy resin over surfaces for coatings and decorative finishes. Resin casting requires precise measuring and curing times to achieve intricate designs, whereas epoxy pouring focuses on fluidity and smooth layering for durable, glossy surfaces. The choice between resin casting and epoxy pouring depends on the desired outcome, with casting excelling in three-dimensional objects and pouring suited for flat, protective, or artistic surfaces.

Materials Needed for Resin Casting vs Epoxy Pouring

Resin casting requires materials such as liquid resin, a hardener, silicone molds, and release agents to ensure proper shaping and curing. Epoxy pouring involves epoxy resin, a curing agent, mixing containers, stirring sticks, and often pigments or dyes for color customization. Both techniques may share protective gear like gloves and masks due to fumes, but the specific resin formulas and mold types differ according to the project's detail and finish requirements.

Project Suitability: When to Use Resin Casting or Epoxy Pouring

Resin casting is ideal for projects requiring precise molds, detailed shapes, and a solid, durable finish such as jewelry, figurines, and intricate decorations. Epoxy pouring suits applications like river tables, bar tops, and surface coatings where a smooth, glossy finish and thicker layer buildup are essential. Choosing between resin casting and epoxy pouring depends on the project's complexity, desired finish, and thickness of the pour.

Surface Preparation and Mold Requirements

Resin casting demands meticulous surface preparation to ensure molds are clean and release agents are properly applied, preventing adhesion issues and surface flaws. Epoxy pouring requires molds that are both rigid and non-porous to withstand the chemical reaction and minimize air bubble formation. Selecting compatible mold materials like silicone or polypropylene is crucial for both techniques to achieve smooth finishes and facilitate easy demolding.

Mixing Techniques and Ratios for Best Results

Resin casting requires precise measuring and thorough mixing of two-part resin and hardener, typically at a 1:1 or 2:1 ratio depending on product specifications, to ensure optimal curing and durability. Epoxy pouring demands slower mixing at a controlled ratio, often 100:43 (resin to hardener), to minimize air bubbles and achieve a smooth, glass-like surface. Both techniques benefit from gradual stirring and temperature control to prevent imperfections and enhance the final finish quality.

Curing Times: What to Expect

Resin casting typically requires longer curing times, often between 24 to 72 hours, depending on the resin type and environmental conditions, making it ideal for detailed molds and intricate designs. Epoxy pouring cures faster, usually within 12 to 24 hours, offering a quicker turnaround for flat surfaces like tabletops or coatings. Understanding these curing time differences helps artisans select the right method for project deadlines and desired finish quality.

Common Mistakes in Resin Casting vs Epoxy Pouring

Common mistakes in resin casting versus epoxy pouring often involve improper mixing ratios, leading to incomplete curing or sticky surfaces. Contamination from dust or moisture can cause cloudiness and bubbles, compromising the clarity of the final product. Overheating during resin casting can distort molds, while epoxy pouring errors frequently stem from inadequate ventilation, resulting in harmful fumes and health risks.

Safety Precautions for Handling Resin and Epoxy

When handling resin casting and epoxy pouring materials, wearing nitrile gloves and working in a well-ventilated area are essential safety precautions to prevent skin irritation and inhalation of harmful fumes. Both resin and epoxy can emit volatile organic compounds (VOCs), so using a respirator rated for organic vapors enhances protection during application and curing stages. Proper storage of uncured resin and epoxy, away from heat sources and direct sunlight, reduces the risk of chemical degradation and accidental exposure.

Final Finishing: Polishing and Detailing Your Project

Resin casting offers a smoother finish that requires less polishing, allowing finer details to emerge clearly after cure. Epoxy pouring often produces thicker layers needing extended sanding and polishing to achieve a glossy, professional look. Both methods benefit from meticulous buffing and resin-specific polishing compounds to enhance clarity and depth in the final project.

Resin casting vs Epoxy pouring Infographic

productdif.com

productdif.com