Laser cutting offers precise, detailed cuts ideal for intricate designs on thin materials like wood, acrylic, and fabric, making it perfect for delicate craft projects. CNC routing excels in cutting thicker materials such as hardwood, plastic, and metal, providing versatility and depth with a robust, mechanical approach. Choosing between laser cutting and CNC routing depends on the material thickness, detail complexity, and desired finish for your craft supplies.

Table of Comparison

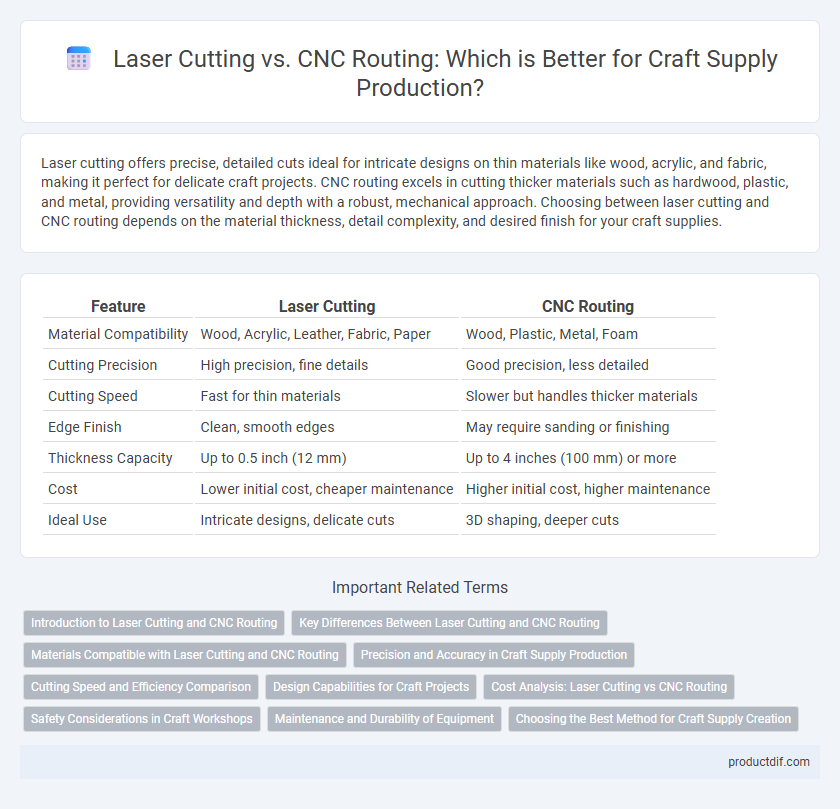

| Feature | Laser Cutting | CNC Routing |

|---|---|---|

| Material Compatibility | Wood, Acrylic, Leather, Fabric, Paper | Wood, Plastic, Metal, Foam |

| Cutting Precision | High precision, fine details | Good precision, less detailed |

| Cutting Speed | Fast for thin materials | Slower but handles thicker materials |

| Edge Finish | Clean, smooth edges | May require sanding or finishing |

| Thickness Capacity | Up to 0.5 inch (12 mm) | Up to 4 inches (100 mm) or more |

| Cost | Lower initial cost, cheaper maintenance | Higher initial cost, higher maintenance |

| Ideal Use | Intricate designs, delicate cuts | 3D shaping, deeper cuts |

Introduction to Laser Cutting and CNC Routing

Laser cutting utilizes a high-powered laser beam to precisely cut or engrave materials such as wood, acrylic, and fabric, offering intricate detail and clean edges ideal for delicate craft projects. CNC routing employs computer-controlled rotary tools to carve, cut, and shape thicker or denser materials like wood, plastics, and foam with high accuracy and repeatability. Both technologies enhance craft supply workflows by enabling customization and complex design creation, though laser cutting excels in fine detail while CNC routing handles heavier, bulkier materials.

Key Differences Between Laser Cutting and CNC Routing

Laser cutting uses a high-powered laser beam to precisely cut or engrave materials like acrylic, wood, and metal with fine detail, while CNC routing employs a rotating cutting tool to carve or shape thicker and denser materials such as hardwood and aluminum. Laser cutting offers superior precision and edge quality ideal for intricate designs, whereas CNC routing provides greater versatility for 3D cutting and handling larger workpieces. The choice between laser cutting and CNC routing depends on factors like material type, desired finish, and project complexity in craft supply applications.

Materials Compatible with Laser Cutting and CNC Routing

Laser cutting excels in processing thin materials such as wood, acrylic, leather, and fabric with high precision and smooth edges, ideal for intricate designs. CNC routing can handle thicker and denser materials like hardwood, plastic, foam, and soft metals, offering robust cutting and shaping capabilities. Both methods complement each other by covering a broad spectrum of materials suited for diverse craft supply projects.

Precision and Accuracy in Craft Supply Production

Laser cutting offers superior precision, achieving intricate details with accuracy down to 0.01 millimeters, making it ideal for delicate craft supply production. CNC routing provides high accuracy, typically around 0.1 millimeters, and excels in cutting thicker materials with consistent repeatability. Selecting between laser cutting and CNC routing depends on the required detail level and material thickness for craft supply manufacturing.

Cutting Speed and Efficiency Comparison

Laser cutting offers significantly faster cutting speeds for intricate designs on thinner materials, achieving precision without physical contact, which reduces material distortion. CNC routing excels in cutting thicker, denser materials like wood and plastic, providing efficient chip removal and higher feed rates for less detailed, bulkier projects. Choosing between laser cutting and CNC routing depends on the balance between speed, material type, and design complexity to optimize overall cutting efficiency in craft supply operations.

Design Capabilities for Craft Projects

Laser cutting offers exceptional precision and intricate detail ideal for complex craft designs, while CNC routing excels in handling thicker materials and creating three-dimensional shapes. Laser cutters provide superior edge quality and fine engraving options, making them perfect for delicate projects such as paper crafts and detailed woodwork. CNC routers support a broader range of materials and can produce deeper cuts, enabling robust and textured craft pieces like furniture components and customized signage.

Cost Analysis: Laser Cutting vs CNC Routing

Laser cutting generally offers lower setup costs for intricate designs, making it ideal for small batch production and detailed craft projects. CNC routing, while having higher initial investment due to robust machinery, provides cost efficiency in high-volume runs and thicker material cutting. Analyzing material types, project complexity, and volume helps determine the more economical choice between laser cutting and CNC routing for craft supply needs.

Safety Considerations in Craft Workshops

Laser cutting requires stringent safety measures including proper ventilation systems to manage hazardous fumes and regular maintenance of protective enclosures to prevent eye and skin exposure. CNC routing involves risks such as flying debris and noise, necessitating the use of safety guards, ear protection, and dust extraction units to safeguard operators. Both processes demand comprehensive training on emergency protocols and equipment handling to minimize injury risks in craft workshops.

Maintenance and Durability of Equipment

Laser cutting machines require regular lens and mirror cleaning along with periodic laser tube replacements to maintain optimal performance, while CNC routers demand frequent lubrication of moving parts and spindle maintenance. The durability of laser cutters heavily depends on the quality of optical components and proper cooling systems, whereas CNC routers benefit from robust mechanical construction and wear-resistant bits. Both technologies necessitate consistent maintenance schedules to ensure longevity and precision in craft supply fabrication.

Choosing the Best Method for Craft Supply Creation

Laser cutting offers precise, intricate designs with smooth edges, ideal for detailed craft supply creation such as leather, acrylic, and wood. CNC routing excels at cutting thicker materials like hardwood and MDF, delivering durability and depth perfect for structural craft components. Selecting between laser cutting and CNC routing depends on material thickness, design complexity, and required finish quality for optimal craft supply results.

Laser cutting vs CNC routing Infographic

productdif.com

productdif.com