Sheet metal offers durability and versatility for crafting projects that require thin, flat pieces with uniform thickness, making it ideal for jewelry, sculptures, and decorative accents. Metal clay, composed of fine metal particles mixed with a binder, allows for intricate detailing and sculpting through molding and firing, transforming into solid metal upon kiln firing. Choosing between sheet metal and metal clay depends on the desired texture, complexity, and structural strength of the final craft product.

Table of Comparison

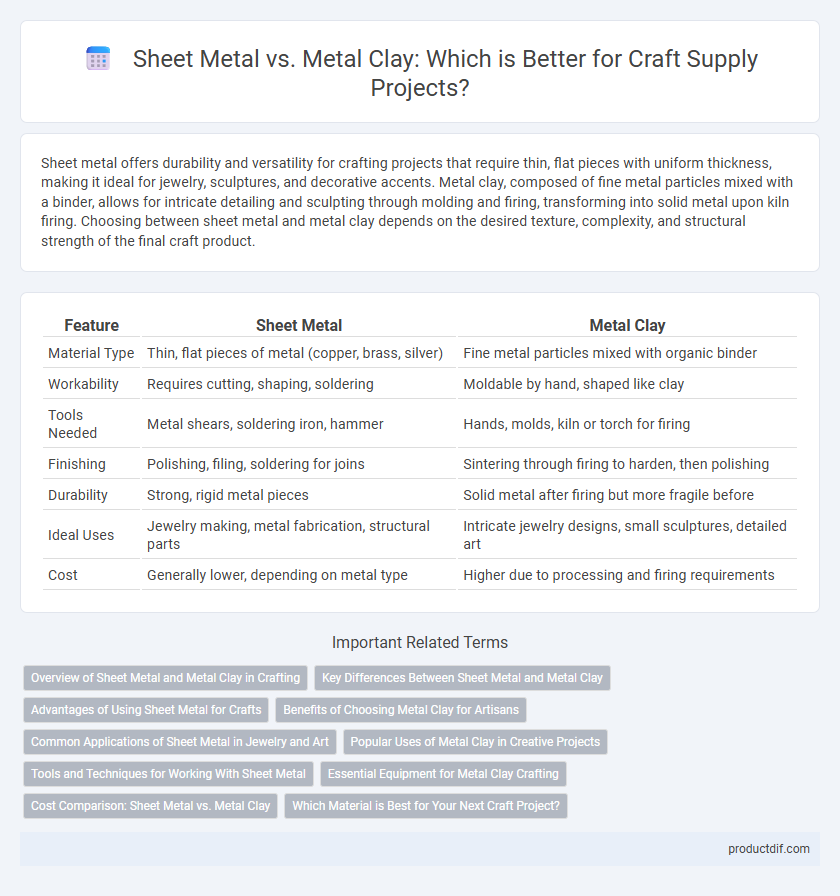

| Feature | Sheet Metal | Metal Clay |

|---|---|---|

| Material Type | Thin, flat pieces of metal (copper, brass, silver) | Fine metal particles mixed with organic binder |

| Workability | Requires cutting, shaping, soldering | Moldable by hand, shaped like clay |

| Tools Needed | Metal shears, soldering iron, hammer | Hands, molds, kiln or torch for firing |

| Finishing | Polishing, filing, soldering for joins | Sintering through firing to harden, then polishing |

| Durability | Strong, rigid metal pieces | Solid metal after firing but more fragile before |

| Ideal Uses | Jewelry making, metal fabrication, structural parts | Intricate jewelry designs, small sculptures, detailed art |

| Cost | Generally lower, depending on metal type | Higher due to processing and firing requirements |

Overview of Sheet Metal and Metal Clay in Crafting

Sheet metal in crafting offers durability and versatility, commonly used for creating structural elements, jewelry, and decorative items through techniques like cutting, bending, and stamping. Metal clay, composed of fine metal particles and an organic binder, allows artists to mold intricate designs that harden after firing, resembling solid metal with a lightweight finish. The choice between sheet metal and metal clay depends on the desired texture, detail, and final application of the craft project.

Key Differences Between Sheet Metal and Metal Clay

Sheet metal consists of thin, flat pieces of metal produced by rolling or hammering, commonly used for structural and durable craft projects, whereas metal clay is a malleable material made of fine metal particles bound with an organic binder, ideal for intricate jewelry making and detailed sculptures. Sheet metal requires cutting, shaping, and welding or soldering with specialized tools, while metal clay allows hand molding and firing in a kiln to create solid metal objects. The key differences lie in their physical forms, working techniques, and end-use applications within craft supplies.

Advantages of Using Sheet Metal for Crafts

Sheet metal offers superior durability and structural integrity compared to metal clay, making it ideal for crafting objects that require strength and longevity. Its smooth surface allows for precise cutting, shaping, and detailed engraving, enhancing the aesthetic quality of finished crafts. Sheet metal also provides a wider range of metal options such as aluminum, copper, and steel, enabling artisans to select materials based on their specific project needs and desired finishes.

Benefits of Choosing Metal Clay for Artisans

Metal clay offers artisans unparalleled versatility and ease of manipulation compared to sheet metal, allowing for intricate designs and fine details that are difficult to achieve with traditional metal sheets. Its lightweight and moldable properties enable efficient crafting of complex jewelry and decorative items without specialized tools or extensive metalworking skills. Metal clay also provides a safer, low-temperature firing process, reducing risks associated with soldering or welding sheet metal.

Common Applications of Sheet Metal in Jewelry and Art

Sheet metal is widely used in jewelry and art for creating structural components, such as bezel settings, metal bands, and decorative plates due to its durability and malleability. Artists often employ sheet metal to fabricate intricate designs, engravings, and textured surfaces that enhance visual appeal and add dimension to their pieces. Its ability to be easily cut, shaped, and soldered makes sheet metal a preferred choice for crafting detailed jewelry items and large-scale metal artwork.

Popular Uses of Metal Clay in Creative Projects

Metal clay is widely used in jewelry making, allowing artists to create intricate pendants, rings, and earrings with fine detail and customizable designs. It is favored for small-scale sculptures and decorative charms due to its ease of shaping and ability to be fired into solid metal. Unlike sheet metal, metal clay offers versatility for detailed artistic projects without requiring extensive metalworking tools.

Tools and Techniques for Working With Sheet Metal

Sheet metal crafting relies on tools such as metal snips, hammers, pliers, and welding equipment to cut, shape, and join metal sheets with precision. Techniques include annealing to soften the metal, embossing for decorative textures, and soldering or riveting to assemble components securely. Mastery of metalworking tools and methods enables crafters to create durable and intricate designs from sheet metal.

Essential Equipment for Metal Clay Crafting

Essential equipment for metal clay crafting includes tools specifically designed for shaping and texturing, such as metal clay molds, texture sheets, and shaping tools. Unlike sheet metal work, which requires heavy-duty tools like metal shears, hammers, and anvils, metal clay crafting relies on precision instruments like brushes, needle tools, and small carving tools that allow for intricate detailing. Kilns or torch setups are also necessary to fire and harden the metal clay, transforming it from a malleable material into solid metal jewelry or ornaments.

Cost Comparison: Sheet Metal vs. Metal Clay

Sheet metal typically costs less per sheet but requires specialized tools and machinery that may increase initial investment, making it cost-effective for large or repetitive projects. Metal clay, while more expensive per gram, offers ease of use with minimal equipment and is ideal for intricate designs and small-scale crafting. Evaluating the total project costs involves balancing material price against tool accessibility and the complexity of the craftwork.

Which Material is Best for Your Next Craft Project?

Sheet metal offers durability and precision ideal for detailed, structural craft projects requiring strength and longevity, while metal clay provides flexibility and ease of shaping, perfect for intricate, sculptural designs or jewelry making. Choosing between sheet metal and metal clay depends on the project's complexity, desired finish, and whether the craft demands metalworking tools or hand-molded creativity. For crafts needing fine texture and lightweight features, metal clay excels, whereas sheet metal is best suited for robust, large-scale creations.

Sheet metal vs Metal clay Infographic

productdif.com

productdif.com