Wet molding offers enhanced flexibility and smoother finishes by using moisture to shape and mold materials, ideal for intricate or delicate craft projects. Dry molding relies on shaping materials without moisture, providing firmer, more rigid results suitable for structural or robust crafts. Choosing between wet molding and dry molding depends on the desired texture, durability, and precision of the final craft piece.

Table of Comparison

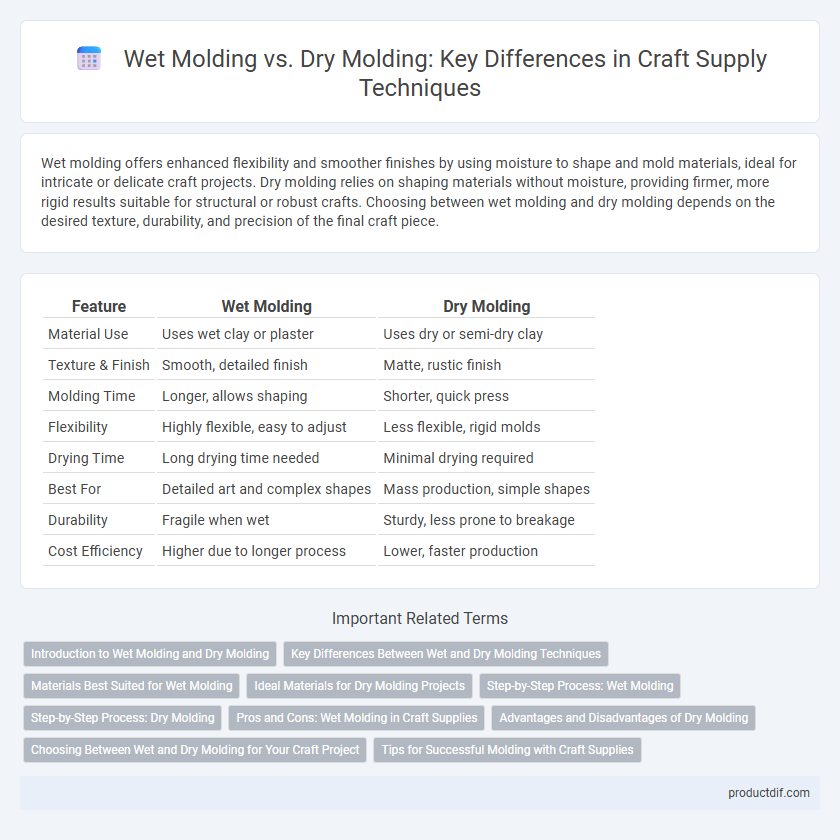

| Feature | Wet Molding | Dry Molding |

|---|---|---|

| Material Use | Uses wet clay or plaster | Uses dry or semi-dry clay |

| Texture & Finish | Smooth, detailed finish | Matte, rustic finish |

| Molding Time | Longer, allows shaping | Shorter, quick press |

| Flexibility | Highly flexible, easy to adjust | Less flexible, rigid molds |

| Drying Time | Long drying time needed | Minimal drying required |

| Best For | Detailed art and complex shapes | Mass production, simple shapes |

| Durability | Fragile when wet | Sturdy, less prone to breakage |

| Cost Efficiency | Higher due to longer process | Lower, faster production |

Introduction to Wet Molding and Dry Molding

Wet molding involves shaping materials, such as clay or papier-mache, when they are moist and pliable, allowing for detailed manipulation and smooth finishes. Dry molding uses rigid or semi-rigid materials like wood or metal that are formed without added moisture, resulting in more structured and durable shapes. Each technique influences the texture and durability of the final craft project, catering to different artistic needs and material properties.

Key Differences Between Wet and Dry Molding Techniques

Wet molding involves shaping materials with the addition of water or other liquids to soften fibers or clay, resulting in smoother surfaces and easier manipulation for detailed designs. Dry molding relies on the use of dry materials, often compressed or heated, offering more structural rigidity and faster setting times but less flexibility during shaping. Key differences include moisture content, workability, drying time, and final texture, making wet molding ideal for intricate, delicate projects and dry molding better suited for robust, uniform shapes.

Materials Best Suited for Wet Molding

Wet molding is best suited for materials like clay, plaster, and papier-mache, which require water to activate binding agents and achieve pliability. These materials benefit from the added moisture to prevent cracking during the shaping process and to enhance adhesion between layers. Porous substances and natural fibers also respond well to wet molding techniques, improving durability and finish quality.

Ideal Materials for Dry Molding Projects

Ideal materials for dry molding projects include lightweight, flexible substances such as leather, kraft paper, and untreated fabrics that easily conform without moisture. These materials maintain structural integrity while allowing precise shaping through pressure and heat. Using dry molding with thermoplastics like polyethylene or polypropylene enhances durability in craft applications requiring stiffness without water exposure.

Step-by-Step Process: Wet Molding

Wet molding involves soaking natural fibers or fabric in water or a resin solution to increase flexibility before shaping them on a mold. The process begins with preparing the mold and impregnating the fibers, followed by carefully laying the wet material onto the mold surface for precise shaping. After shaping, the molded item undergoes drying or curing to harden the form and ensure durability.

Step-by-Step Process: Dry Molding

Dry molding in craft supplies involves shaping materials without added moisture, starting by selecting and cutting the material into the desired form. The next step is to apply pressure or heat to mold the material, ensuring it retains the shape as it cools or sets. This process is ideal for materials like clay or synthetic fibers that harden upon drying, enabling precise, durable craft creations.

Pros and Cons: Wet Molding in Craft Supplies

Wet molding in craft supplies offers superior flexibility and precision, allowing intricate shapes and smooth finishes for resin, clay, or papier-mache projects. The process enhances adhesion and durability but requires longer drying times and careful moisture control to avoid warping or cracking. Despite its complexity, wet molding is ideal for detailed artistry where texture and seamless joins are critical.

Advantages and Disadvantages of Dry Molding

Dry molding offers advantages such as faster curing times and easier handling since it does not require moisture or resin, making it ideal for quick prototyping and lightweight crafts. However, its disadvantages include reduced material strength and less flexibility compared to wet molding, limiting its use for structurally demanding projects. Dry molding also tends to produce rougher finishes, requiring additional sanding or coating for a smooth final product.

Choosing Between Wet and Dry Molding for Your Craft Project

Choosing between wet molding and dry molding depends on your craft project's material requirements and desired finish. Wet molding involves shaping materials soaked in water or adhesive to achieve smooth, flexible forms, ideal for clay or papier-mache crafts. Dry molding suits firm, pre-dried materials like leather or stiff fabrics, providing structure and durability without moisture-induced warping.

Tips for Successful Molding with Craft Supplies

For successful molding with craft supplies, selecting the right type between wet molding and dry molding is crucial, as wet molding involves using moisture for flexibility while dry molding relies on shaping materials in their current rigidity. To optimize results, thoroughly prepare the mold by cleaning and lightly oiling it to prevent sticking and ensure detail preservation. Using consistent pressure during molding and allowing adequate drying or curing time enhances the durability and precision of the final craft piece.

Wet Molding vs Dry Molding Infographic

productdif.com

productdif.com