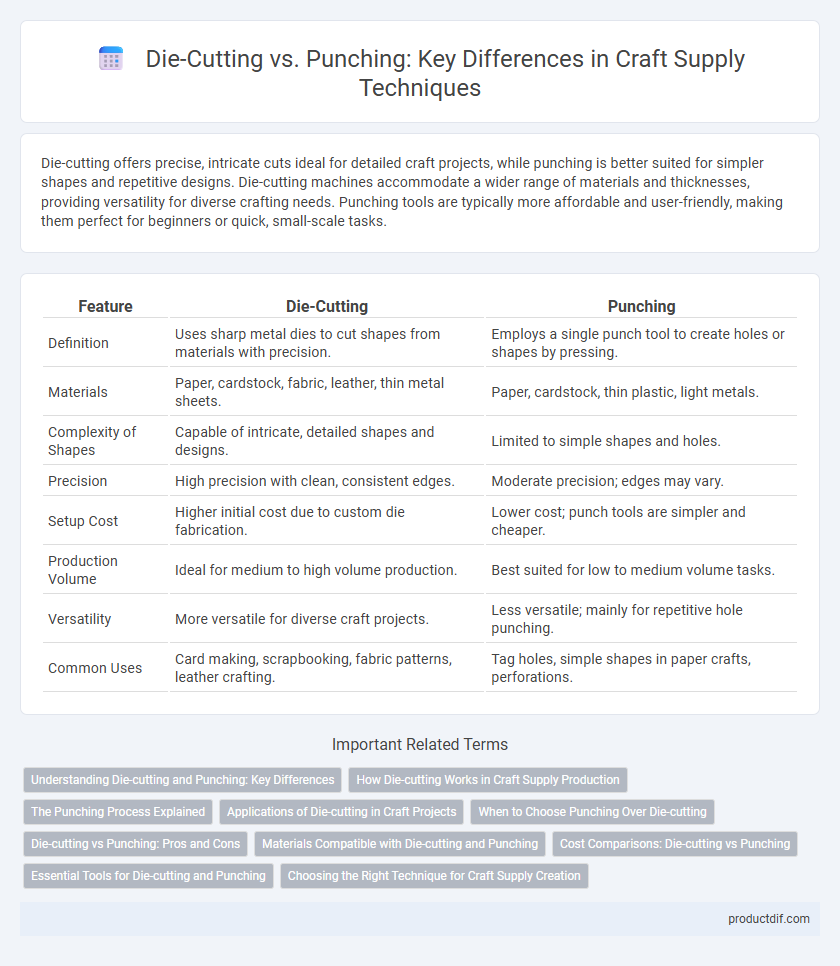

Die-cutting offers precise, intricate cuts ideal for detailed craft projects, while punching is better suited for simpler shapes and repetitive designs. Die-cutting machines accommodate a wider range of materials and thicknesses, providing versatility for diverse crafting needs. Punching tools are typically more affordable and user-friendly, making them perfect for beginners or quick, small-scale tasks.

Table of Comparison

| Feature | Die-Cutting | Punching |

|---|---|---|

| Definition | Uses sharp metal dies to cut shapes from materials with precision. | Employs a single punch tool to create holes or shapes by pressing. |

| Materials | Paper, cardstock, fabric, leather, thin metal sheets. | Paper, cardstock, thin plastic, light metals. |

| Complexity of Shapes | Capable of intricate, detailed shapes and designs. | Limited to simple shapes and holes. |

| Precision | High precision with clean, consistent edges. | Moderate precision; edges may vary. |

| Setup Cost | Higher initial cost due to custom die fabrication. | Lower cost; punch tools are simpler and cheaper. |

| Production Volume | Ideal for medium to high volume production. | Best suited for low to medium volume tasks. |

| Versatility | More versatile for diverse craft projects. | Less versatile; mainly for repetitive hole punching. |

| Common Uses | Card making, scrapbooking, fabric patterns, leather crafting. | Tag holes, simple shapes in paper crafts, perforations. |

Understanding Die-cutting and Punching: Key Differences

Die-cutting uses a sharp steel blade shaped into a specific design to cut intricate patterns or shapes from materials like paper, fabric, or vinyl, offering precision and versatility ideal for detailed craft projects. Punching employs a simpler mechanism with a metal punch and die set to create uniform holes or basic shapes, typically used for repetitive, less complex cuts. Understanding these differences helps crafters choose die-cutting for elaborate designs and punching for straightforward, efficient hole or shape creation.

How Die-cutting Works in Craft Supply Production

Die-cutting in craft supply production involves using a sharp steel blade shaped into a specific design, mounted on a die to cut materials like paper, fabric, or leather with precision and consistency. The die is pressed onto the material using a die-cutting machine, which applies controlled pressure to ensure clean, accurate cuts, enabling complex shapes or patterns that manual cutting cannot achieve. This process enhances efficiency and versatility in craft creation, offering customized and repeatable results critical for high-quality craft supply products.

The Punching Process Explained

Punching in craft supply involves using a die or punch tool to create precise shapes by forcibly cutting through material, typically paper, fabric, or thin metal. This process differs from die-cutting by applying pressure directly to the punch, which removes the cut-out portion from the base material without the need for a cutting machine. Punching ensures clean edges and fast production of repetitive shapes, making it ideal for tasks requiring uniform precision and speed.

Applications of Die-cutting in Craft Projects

Die-cutting enables precise and intricate shapes in paper, fabric, and thin metal, making it ideal for scrapbooking, card making, and textile designs. This technique supports repetitive and consistent cuts, enhancing efficiency in producing embellishments, stencils, and personalized decals. Versatility in material types and detailed patterns distinguishes die-cutting as a preferred method in diverse craft projects.

When to Choose Punching Over Die-cutting

Punching is ideal for high-volume production runs requiring simple shapes with consistent accuracy, as it offers faster setup and lower unit costs compared to die-cutting. Choose punching when working with thin materials like paper, cardstock, or foil, where the clean, repetitive cuts maximize efficiency and reduce material waste. This method is most effective for uniform designs such as tags, labels, or confetti, enabling quick output without sacrificing quality.

Die-cutting vs Punching: Pros and Cons

Die-cutting offers precise, intricate shapes and consistent results, making it ideal for detailed craft projects, while punching is faster and more cost-effective for simple shapes but limited in design complexity. Die-cutting requires specialized dies and machinery, increasing initial costs but providing versatility and repeatability, whereas punching tools are generally manual and less expensive but offer less accuracy. Craft enthusiasts should choose die-cutting for professional-quality, complex designs and punching for quick, straightforward cuts with minimal setup.

Materials Compatible with Die-cutting and Punching

Die-cutting works efficiently with thin, flexible materials like paper, fabric, vinyl, and foam, offering precise and intricate designs ideal for crafts and packaging. Punching suits thicker, more rigid materials such as leather, cardboard, and plastic sheets, providing quick, consistent holes or shapes without detailed complexity. Selecting the right technique depends on the material thickness and desired design intricacy for optimal crafting results.

Cost Comparisons: Die-cutting vs Punching

Die-cutting generally involves higher upfront costs due to the creation of custom dies, making it more cost-effective for large production runs with complex shapes. Punching offers lower initial expenses and faster setup times, ideal for simpler designs and smaller quantities. Evaluating volume requirements and design complexity is crucial to optimize cost-efficiency between die-cutting and punching in craft supply projects.

Essential Tools for Die-cutting and Punching

Essential tools for die-cutting include steel rule dies, silicone mats, and die-cutting machines like Sizzix or Cricut that provide precise and repeatable cuts for various materials. Punching requires handheld or mounted punches designed for specific shapes, often used for quick and simpler cuts on paper, cardstock, and thin materials. Both tools enhance crafting efficiency, but die-cutting offers greater versatility with complex designs, while punching is valued for speed and ease of use.

Choosing the Right Technique for Craft Supply Creation

Die-cutting offers precise and intricate shapes for craft projects, ideal for detailed designs in paper, fabric, and thin metal. Punching is better suited for simpler shapes and repetitive patterns, providing efficiency in bulk production of craft supplies. Selecting the right technique depends on the complexity of the design, material thickness, and quantity needed for craft supply creation.

Die-cutting vs Punching Infographic

productdif.com

productdif.com