Hand weaving offers intricate control and flexibility, allowing artisans to create unique, detailed patterns suited for personalized craft supplies. Loom weaving enhances efficiency and consistency by producing uniform fabrics quickly, ideal for bulk pet accessory production. Choosing between hand weaving and loom weaving depends on the desired balance of craftsmanship and volume in pet supply manufacturing.

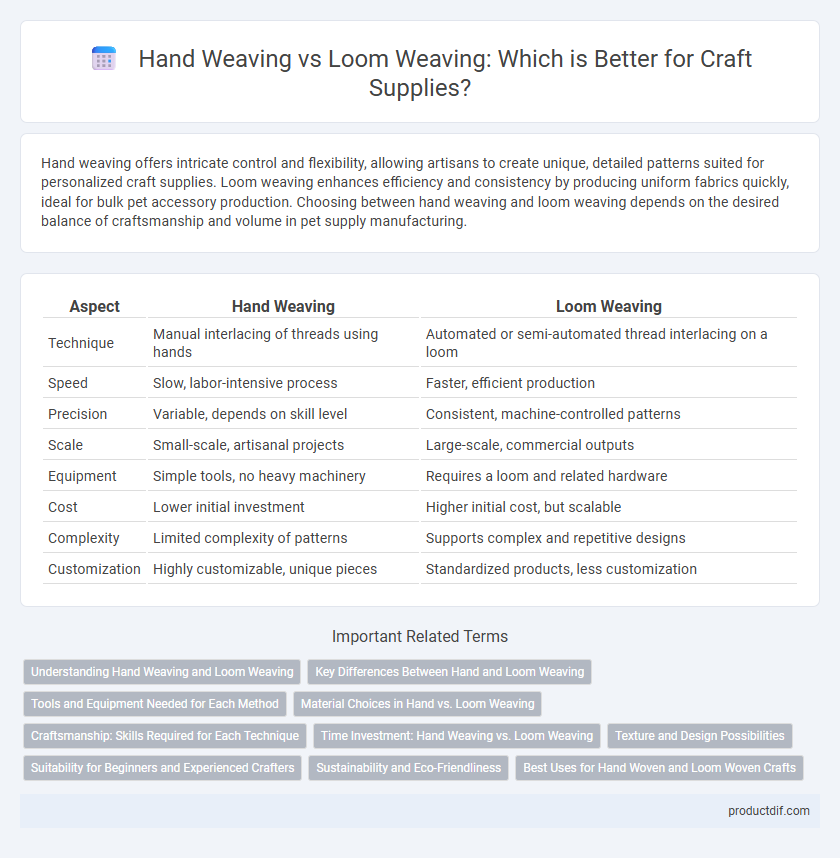

Table of Comparison

| Aspect | Hand Weaving | Loom Weaving |

|---|---|---|

| Technique | Manual interlacing of threads using hands | Automated or semi-automated thread interlacing on a loom |

| Speed | Slow, labor-intensive process | Faster, efficient production |

| Precision | Variable, depends on skill level | Consistent, machine-controlled patterns |

| Scale | Small-scale, artisanal projects | Large-scale, commercial outputs |

| Equipment | Simple tools, no heavy machinery | Requires a loom and related hardware |

| Cost | Lower initial investment | Higher initial cost, but scalable |

| Complexity | Limited complexity of patterns | Supports complex and repetitive designs |

| Customization | Highly customizable, unique pieces | Standardized products, less customization |

Understanding Hand Weaving and Loom Weaving

Hand weaving involves manually interlacing warp and weft threads using hand-held tools, allowing for intricate patterns and unique textures in craft supply projects. Loom weaving utilizes a mechanical or frame loom to hold warp threads taut, enabling faster production and consistent fabric tension for larger-scale crafts. Both techniques offer distinct creative advantages, with hand weaving prioritizing artisanal detail and loom weaving emphasizing efficiency and uniformity.

Key Differences Between Hand and Loom Weaving

Hand weaving offers greater control over intricate patterns and textures, emphasizing artisan skill and flexibility in design. Loom weaving enables higher production speed and uniformity, relying on mechanized or foot-powered frames to maintain consistent tension and spacing. Differences in scale, precision, and output efficiency define the choice between hand and loom weaving in craft supplies.

Tools and Equipment Needed for Each Method

Hand weaving requires basic tools such as a heddle, shuttle, and a simple frame loom, allowing for portability and ease of setup. Loom weaving involves more complex equipment like rigid heddle looms or floor looms, which provide greater control and allow for intricate patterns but require a dedicated space. Both methods rely on essential tools such as yarn, warp threads, and shuttles, but loom weaving demands advanced machinery for tension control and higher productivity.

Material Choices in Hand vs. Loom Weaving

Hand weaving often utilizes natural fibers such as cotton, wool, and silk, allowing artisans to experiment with texture and color on a smaller scale. Loom weaving supports a broader range of materials, including synthetic fibers like nylon and polyester, enabling higher tension and uniform fabric production. The choice of material directly influences the durability, flexibility, and final appearance of the woven textile in both techniques.

Craftsmanship: Skills Required for Each Technique

Hand weaving demands intricate manual dexterity and intimate fabric knowledge, showcasing artisan skill through each thread's placement, while loom weaving relies on operating mechanized equipment, emphasizing precision and consistent tension control. Mastery in hand weaving often involves years of practice to perfect patterns and textures without device assistance, contrasting with loom weaving's focus on mechanical setup, pattern programming, and speed efficiency. Both techniques require a deep understanding of fiber behavior and design principles, but hand weaving highlights individual craftsmanship, whereas loom weaving underscores technical proficiency and production scalability.

Time Investment: Hand Weaving vs. Loom Weaving

Hand weaving demands significant time investment due to manual thread interlacing, enhancing craft detail and uniqueness. Loom weaving accelerates production by mechanizing thread alignment and weaving processes, optimizing efficiency for larger projects. Choosing between hand weaving and loom weaving depends on desired craftsmanship quality and time availability.

Texture and Design Possibilities

Hand weaving offers rich texture variation through manual tension control, resulting in unique, tactile fabric surfaces ideal for custom designs. Loom weaving provides consistent weave patterns with precise tension, enabling intricate and repetitive designs across larger fabric widths. Both techniques expand creative possibilities, but hand weaving emphasizes artisanal texture while loom weaving excels in detailed, uniform patterns.

Suitability for Beginners and Experienced Crafters

Hand weaving offers a tactile and flexible approach ideal for beginners seeking to understand basic weaving techniques without complex equipment, allowing for easy experimentation with patterns and materials. Loom weaving, favored by experienced crafters, provides greater precision and efficiency, supporting intricate designs and larger projects through mechanical tension control and structured setups. Both methods cater to different skill levels and project scopes, making hand weaving suitable for learning foundational skills and loom weaving optimal for advanced craftsmanship and professional-quality textiles.

Sustainability and Eco-Friendliness

Hand weaving utilizes minimal energy and produces less waste compared to loom weaving, making it a more sustainable craft supply choice. Natural fibers like organic cotton and wool are often preferred in hand weaving, enhancing its eco-friendliness by reducing reliance on synthetic materials. The slower production process of hand weaving supports sustainable practices by promoting quality and longevity over mass production.

Best Uses for Hand Woven and Loom Woven Crafts

Hand weaving excels in creating intricate, artisanal patterns ideal for unique home decor items and personalized accessories, where detailed craftsmanship is valued. Loom weaving suits large-scale textile production such as fabric for clothing, upholstery, and curtains, offering consistent weave and durability. Both techniques serve different craft supply needs, with hand weaving enhancing bespoke projects and loom weaving supporting efficient fabric manufacturing.

Hand weaving vs Loom weaving Infographic

productdif.com

productdif.com