Heat Transfer Vinyl (HTV) is designed for fabric applications, offering flexibility and durability after heat pressing, making it ideal for customizing clothing and textiles. Adhesive Vinyl, on the other hand, features a sticky backing perfect for applying to hard, non-porous surfaces like glass, plastic, or metal, providing long-lasting decals and signs. Understanding the distinct uses of HTV and Adhesive Vinyl ensures optimal project results and material performance in craft supply projects.

Table of Comparison

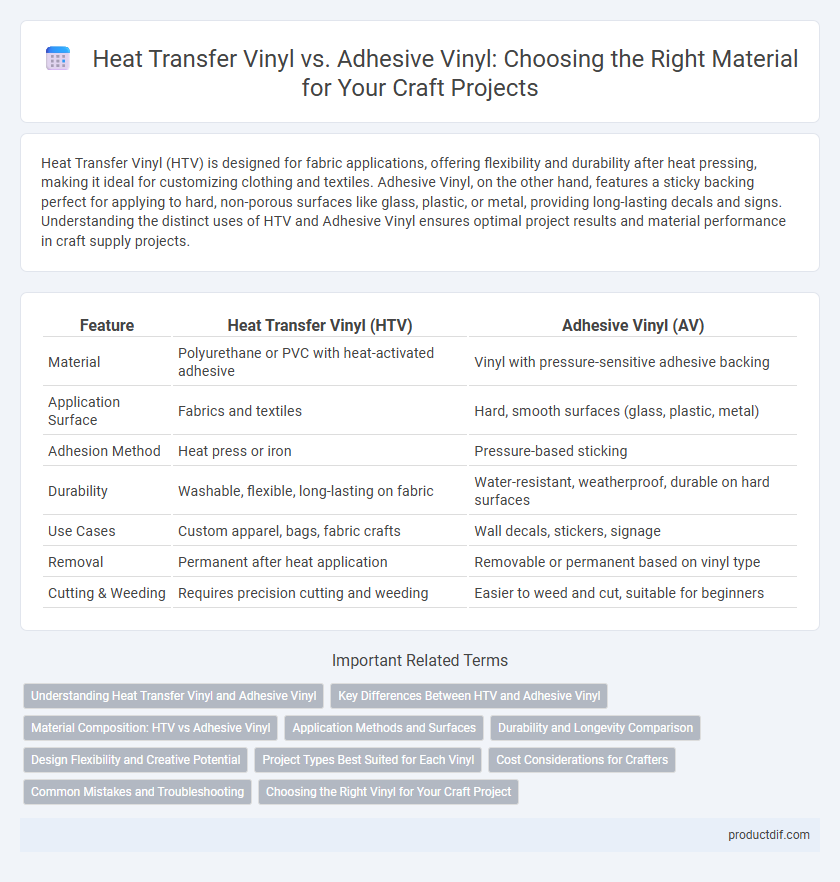

| Feature | Heat Transfer Vinyl (HTV) | Adhesive Vinyl (AV) |

|---|---|---|

| Material | Polyurethane or PVC with heat-activated adhesive | Vinyl with pressure-sensitive adhesive backing |

| Application Surface | Fabrics and textiles | Hard, smooth surfaces (glass, plastic, metal) |

| Adhesion Method | Heat press or iron | Pressure-based sticking |

| Durability | Washable, flexible, long-lasting on fabric | Water-resistant, weatherproof, durable on hard surfaces |

| Use Cases | Custom apparel, bags, fabric crafts | Wall decals, stickers, signage |

| Removal | Permanent after heat application | Removable or permanent based on vinyl type |

| Cutting & Weeding | Requires precision cutting and weeding | Easier to weed and cut, suitable for beginners |

Understanding Heat Transfer Vinyl and Adhesive Vinyl

Heat Transfer Vinyl (HTV) is a flexible material designed for fabric decoration, applied using heat and pressure to bond with textiles, making it ideal for custom apparel. Adhesive Vinyl, also known as sticky vinyl, features a sticky backing suited for hard surfaces like glass, plastic, or wood, perfect for decals, stickers, and signage. Understanding the application, surface compatibility, and durability of HTV versus Adhesive Vinyl ensures the right choice for craft projects.

Key Differences Between HTV and Adhesive Vinyl

Heat Transfer Vinyl (HTV) is designed for fabric applications, adhering through heat activation and providing a flexible, durable finish that withstands washing. Adhesive Vinyl, on the other hand, uses a sticky backing for direct application on rigid surfaces like glass, plastic, or metal, offering a smooth, weather-resistant coating ideal for signage and decals. Key differences include their bonding methods, suitable surfaces, and durability, with HTV excelling on textiles and Adhesive Vinyl preferred for non-porous materials.

Material Composition: HTV vs Adhesive Vinyl

Heat Transfer Vinyl (HTV) is composed of polyurethane or polyester materials designed to bond with fabric fibers through heat and pressure, creating a flexible, durable finish ideal for apparel decoration. Adhesive Vinyl, commonly made from PVC or removable vinyl materials, features a sticky backing that adheres to hard surfaces such as glass, plastic, or wood without heat application. The material composition of HTV allows it to withstand multiple washes, whereas adhesive vinyl is more suitable for temporary or semi-permanent applications on smooth, non-fabric surfaces.

Application Methods and Surfaces

Heat Transfer Vinyl (HTV) is designed for fabric applications and requires a heat press or iron to bond the vinyl to textiles, making it ideal for customizing clothing and soft goods. Adhesive Vinyl uses a pressure-sensitive adhesive backing and is applied by peeling and sticking, suitable for hard, smooth surfaces like glass, plastic, metal, and wood. Understanding the material's compatibility with surfaces and the specific application methods ensures durable and professional results in craft projects.

Durability and Longevity Comparison

Heat Transfer Vinyl (HTV) offers superior durability for fabric applications, withstanding multiple wash cycles and maintaining vibrant colors for years. Adhesive Vinyl excels on hard surfaces, providing strong, weather-resistant adhesion but tends to peel or fade faster when exposed to constant friction or outdoor elements. Choosing between HTV and Adhesive Vinyl depends on the intended use, with HTV favored for clothing longevity and Adhesive Vinyl preferred for durable signage and decor.

Design Flexibility and Creative Potential

Heat Transfer Vinyl (HTV) offers superior design flexibility for fabric projects with its ability to layer colors and create intricate, multi-dimensional designs, making it ideal for custom apparel and textile crafts. Adhesive Vinyl excels in versatility for hard surfaces, providing durable, weather-resistant decoration options perfect for home decor, signage, and personalized gifts. Choosing HTV or Adhesive Vinyl depends on the creative potential required and the material of the project, optimizing artistic expression in both textile and non-textile crafts.

Project Types Best Suited for Each Vinyl

Heat Transfer Vinyl (HTV) is ideal for fabric-based projects such as custom apparel, tote bags, and home textiles due to its heat-activated adhesive that bonds securely to cloth fibers. Adhesive Vinyl excels in creating durable decals, signs, mugs, and wall art, sticking effectively to hard, smooth surfaces like glass, plastic, and metal. Choosing between HTV and Adhesive Vinyl depends on the project substrate and desired durability, with HTV favored for wearable designs and Adhesive Vinyl preferred for rigid or semi-rigid items.

Cost Considerations for Crafters

Heat transfer vinyl (HTV) typically costs more per yard than adhesive vinyl due to its specialized heat-activated backing that requires a heat press or iron for application. Adhesive vinyl offers a more budget-friendly option, especially for large projects, because it can be applied directly to surfaces without additional equipment. Crafters should factor in both material costs and the potential need for heat pressing tools when choosing between HTV and adhesive vinyl for their crafting projects.

Common Mistakes and Troubleshooting

Common mistakes when using heat transfer vinyl (HTV) include incorrect temperature settings, peeling too soon, and improper alignment, which can cause incomplete adhesion or lifting edges. Adhesive vinyl errors often involve insufficient surface cleaning, uneven application, and using low-quality transfer tape, leading to bubbles and poor sticking. Troubleshooting involves adjusting heat press time and temperature for HTV, thoroughly prepping surfaces for adhesive vinyl, and using quality tools to ensure smooth, durable results.

Choosing the Right Vinyl for Your Craft Project

Heat Transfer Vinyl (HTV) is ideal for fabric projects due to its ability to bond securely with textiles using heat and pressure, offering durability and flexibility for custom apparel and soft goods. Adhesive Vinyl excels on hard, non-porous surfaces like glass, plastic, and wood, providing a strong, long-lasting adhesive suitable for decals, labels, and home decor. Selecting the right vinyl depends on the surface material and intended use, ensuring optimal adhesion, finish, and longevity for your craft project.

Heat Transfer Vinyl vs Adhesive Vinyl Infographic

productdif.com

productdif.com