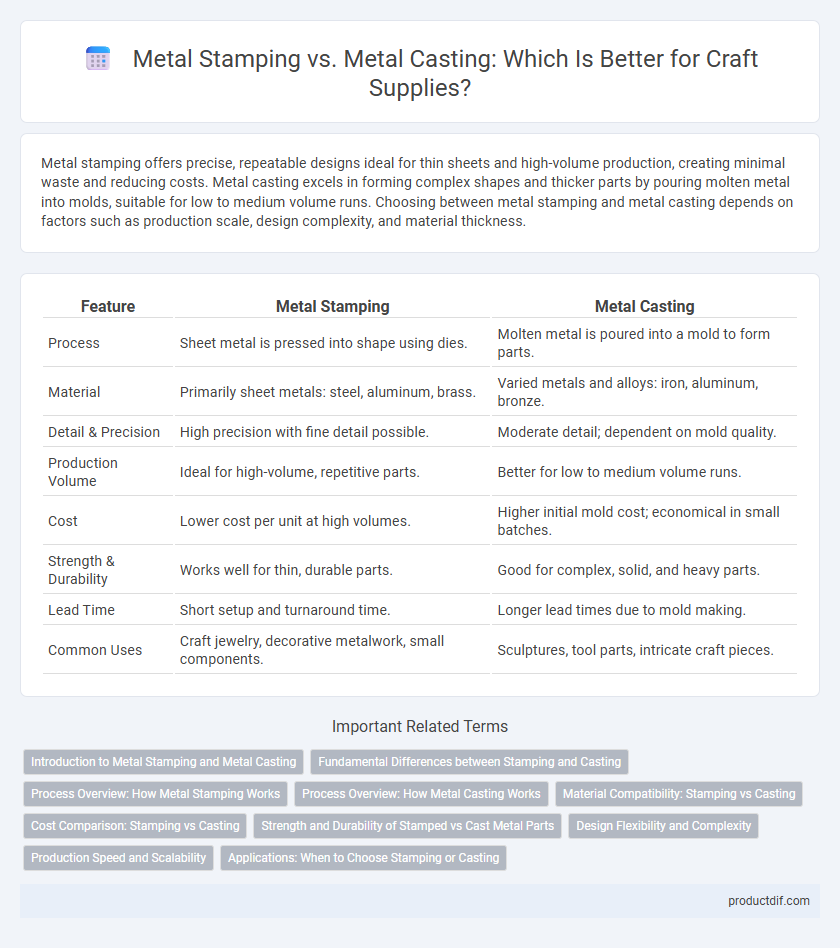

Metal stamping offers precise, repeatable designs ideal for thin sheets and high-volume production, creating minimal waste and reducing costs. Metal casting excels in forming complex shapes and thicker parts by pouring molten metal into molds, suitable for low to medium volume runs. Choosing between metal stamping and metal casting depends on factors such as production scale, design complexity, and material thickness.

Table of Comparison

| Feature | Metal Stamping | Metal Casting |

|---|---|---|

| Process | Sheet metal is pressed into shape using dies. | Molten metal is poured into a mold to form parts. |

| Material | Primarily sheet metals: steel, aluminum, brass. | Varied metals and alloys: iron, aluminum, bronze. |

| Detail & Precision | High precision with fine detail possible. | Moderate detail; dependent on mold quality. |

| Production Volume | Ideal for high-volume, repetitive parts. | Better for low to medium volume runs. |

| Cost | Lower cost per unit at high volumes. | Higher initial mold cost; economical in small batches. |

| Strength & Durability | Works well for thin, durable parts. | Good for complex, solid, and heavy parts. |

| Lead Time | Short setup and turnaround time. | Longer lead times due to mold making. |

| Common Uses | Craft jewelry, decorative metalwork, small components. | Sculptures, tool parts, intricate craft pieces. |

Introduction to Metal Stamping and Metal Casting

Metal stamping involves shaping flat metal sheets into specific forms using a press and dies, offering high precision and efficiency for producing intricate designs. Metal casting entails pouring molten metal into molds to create complex shapes, suitable for larger and heavier components with detailed features. Both techniques are fundamental in craft supply, providing diverse options for creating decorative and functional metal pieces.

Fundamental Differences between Stamping and Casting

Metal stamping involves shaping metal sheets using dies and high-pressure presses to create precise, thin, and consistent components ideal for intricate designs. Metal casting requires pouring molten metal into molds to form complex, bulky shapes with varying thickness and detailed internal geometries. The fundamental difference lies in stamping's deformation of solid metal sheets versus casting's process of solidifying liquid metal into a desired form.

Process Overview: How Metal Stamping Works

Metal stamping involves placing flat metal sheets into a stamping press where a tool and die apply pressure to cut, shape, or form the metal into precise parts. This process offers high speed and repeatability, making it ideal for producing large volumes of components with consistent quality. Key metals used in stamping include steel, aluminum, and brass, which allow for durable and detailed craft supply creations.

Process Overview: How Metal Casting Works

Metal casting involves pouring molten metal into a mold where it cools and solidifies into the desired shape, making it ideal for creating complex and detailed designs in craft supply projects. This process allows for high precision and repeatability, accommodating various metals such as aluminum, brass, and bronze. The ability to produce intricate textures and detailed components sets metal casting apart from metal stamping, especially in custom craft applications.

Material Compatibility: Stamping vs Casting

Metal stamping excels with ductile metals such as aluminum, copper, and mild steel, allowing precise shaping without melting the material. Metal casting accommodates a wider array of metals, including those with higher melting points like cast iron and bronze, enabling complex geometries through molten material molding. Understanding metal compatibility is critical for selecting stamping or casting methods based on project specifications and material properties.

Cost Comparison: Stamping vs Casting

Metal stamping offers lower upfront costs due to minimal tooling expenses, making it ideal for high-volume production runs in craft supply manufacturing. Metal casting involves higher initial investments in molds and setup but becomes cost-effective for complex designs and smaller batch sizes. Overall, stamping typically reduces per-unit costs faster, while casting excels in cost-efficiency when intricate shapes and material versatility are required.

Strength and Durability of Stamped vs Cast Metal Parts

Metal stamping produces parts with higher strength and consistent durability due to work hardening during the stamping process, making them ideal for applications requiring precision and resistance to deformation. Cast metal parts, while allowing complex shapes, often exhibit lower tensile strength and may have porosity issues that reduce long-term durability. Choosing stamped metals ensures superior mechanical properties and extended lifespan in high-stress craft supply components.

Design Flexibility and Complexity

Metal stamping offers limited design flexibility, best suited for simple, repetitive shapes with high precision and tight tolerances. Metal casting enables the creation of intricate, complex geometries and undercuts due to molten metal filling detailed molds, supporting more diverse and customizable designs. Choosing between stamping and casting depends on the required design complexity, production volume, and material properties desired for craft supply projects.

Production Speed and Scalability

Metal stamping offers significantly faster production speeds due to its automated, high-volume processing capabilities, making it ideal for large-scale craft supply runs. In contrast, metal casting involves longer cycle times because of mold preparation and cooling phases, limiting rapid scalability. Scalability in metal stamping benefits from efficient tool changes and mass production, while metal casting excels in creating complex shapes but at slower output rates.

Applications: When to Choose Stamping or Casting

Metal stamping is ideal for high-volume production of thin, uniform parts such as brackets, hinges, and electronic components, offering precision and cost-efficiency for simpler shapes. Metal casting excels in producing complex, heavy-duty parts like engine blocks, pump housings, and decorative art pieces where intricate geometries and strength are essential. Choose stamping for speed and consistency in mass production, while casting suits customized, robust parts with intricate designs.

Metal Stamping vs Metal Casting Infographic

productdif.com

productdif.com