Cold porcelain offers a lightweight, air-drying alternative ideal for delicate, detailed craft projects, while polymer clay requires oven baking, providing greater durability and a firmer finish. Cold porcelain is favored for its smooth texture and ease of hand-molding, making it perfect for floral designs and decorative sculptures. Polymer clay excels in versatility, available in various colors and effects, suitable for jewelry, miniatures, and functional art pieces.

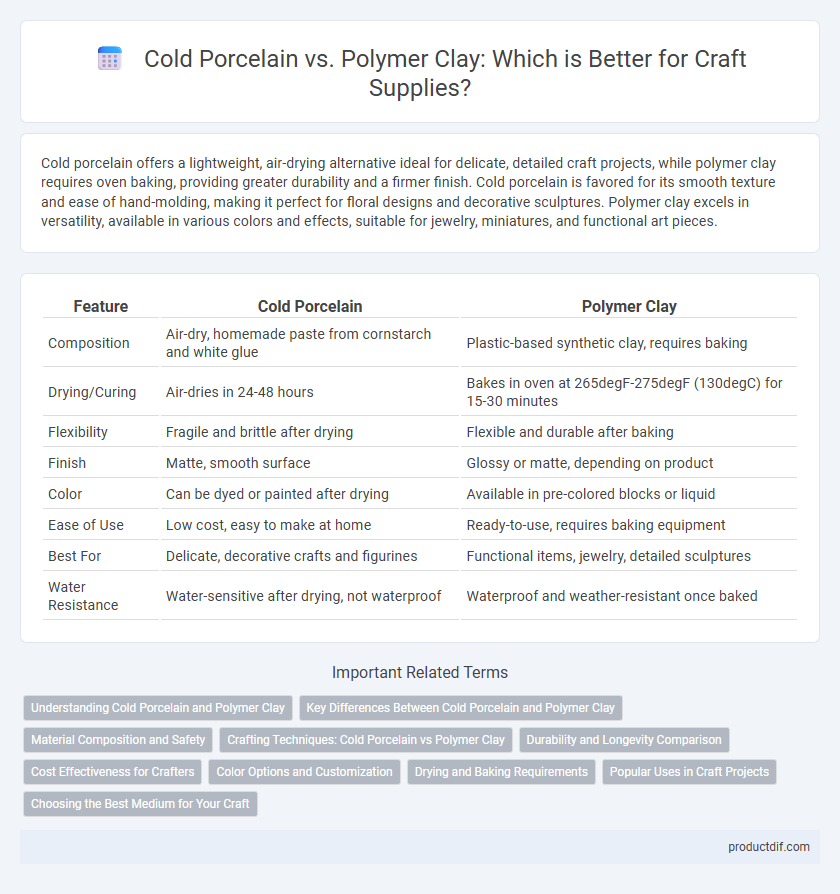

Table of Comparison

| Feature | Cold Porcelain | Polymer Clay |

|---|---|---|

| Composition | Air-dry, homemade paste from cornstarch and white glue | Plastic-based synthetic clay, requires baking |

| Drying/Curing | Air-dries in 24-48 hours | Bakes in oven at 265degF-275degF (130degC) for 15-30 minutes |

| Flexibility | Fragile and brittle after drying | Flexible and durable after baking |

| Finish | Matte, smooth surface | Glossy or matte, depending on product |

| Color | Can be dyed or painted after drying | Available in pre-colored blocks or liquid |

| Ease of Use | Low cost, easy to make at home | Ready-to-use, requires baking equipment |

| Best For | Delicate, decorative crafts and figurines | Functional items, jewelry, detailed sculptures |

| Water Resistance | Water-sensitive after drying, not waterproof | Waterproof and weather-resistant once baked |

Understanding Cold Porcelain and Polymer Clay

Cold porcelain is an air-dry clay made from cornstarch, white glue, and glycerin, known for its smooth texture and lightweight finish, making it ideal for delicate, detailed crafts and floral decorations. Polymer clay, a synthetic plastic-based material, requires baking at low temperatures to harden, offering greater durability, vibrant colors, and versatility for sculpting jewelry, figurines, and intricate designs. Both materials differ in curing methods and final texture, influencing their suitability for various craft projects and artistic techniques.

Key Differences Between Cold Porcelain and Polymer Clay

Cold porcelain is an air-dry clay made primarily from cornstarch and white glue, offering a lightweight and porous texture ideal for delicate, detailed sculptures and flowers. Polymer clay is a synthetic modeling compound that hardens when baked at low temperatures, providing a durable, non-porous finish suitable for jewelry, miniatures, and functional items. Cold porcelain remains flexible and lightweight after drying but is less water-resistant, whereas polymer clay cures into a strong, waterproof material with greater longevity.

Material Composition and Safety

Cold porcelain is a non-toxic air-dry clay made primarily from cornstarch, white glue, and oils, offering a natural and safe option for crafting without the need for baking. Polymer clay, composed of polyvinyl chloride (PVC) and plasticizers, requires heat curing to harden and may release fumes if improperly baked, necessitating good ventilation and caution during use. Both materials are favored for detailed modeling, but cold porcelain is preferred for allergy-sensitive users seeking an eco-friendly, non-baking craft medium.

Crafting Techniques: Cold Porcelain vs Polymer Clay

Cold porcelain crafting techniques emphasize hand molding and air drying, enabling detailed, lightweight sculptures without the use of heat. Polymer clay requires baking in an oven to harden, allowing for intricate layering and texturing with a durable finish ideal for detailed miniature art and jewelry. Both materials support versatile sculpting methods, but cold porcelain offers flexible air-dried results, while polymer clay provides heat-cured robustness.

Durability and Longevity Comparison

Cold porcelain offers a lightweight and flexible finish but tends to be less durable and more prone to cracking over time compared to polymer clay. Polymer clay exhibits superior longevity due to its strong, resilient properties and better resistance to environmental factors like moisture and temperature changes. Consequently, polymer clay is preferred for crafting items that require lasting durability and structural integrity.

Cost Effectiveness for Crafters

Cold porcelain offers a highly cost-effective option for crafters due to its inexpensive raw materials like cornstarch and white glue, enabling bulk production at a low price. Polymer clay tends to be pricier per ounce but provides superior durability and a wider range of vibrant colors, potentially reducing the need for multiple batches and touch-ups. For budget-conscious crafters focusing on large projects, cold porcelain minimizes material expenses, while polymer clay is a better investment for detailed, long-lasting creations.

Color Options and Customization

Cold porcelain offers a wide range of pastel and natural tones that can be easily mixed to create custom shades, ideal for delicate, matte-finish crafts. Polymer clay boasts vibrant, bold color options and allows for extensive customization through blending, adding mica powders, or embedding various textures to achieve unique effects. Both materials provide versatile color choices, but polymer clay stands out for its dynamic hues and advanced customizability suited for detailed, colorful designs.

Drying and Baking Requirements

Cold porcelain air-dries naturally at room temperature within 24 to 48 hours, offering a smooth finish without the need for baking. Polymer clay requires baking in an oven at temperatures typically between 265degF and 275degF (130degC to 135degC) for 15 to 30 minutes to harden effectively. The choice between cold porcelain and polymer clay depends heavily on project timing and available tools, as cold porcelain is ideal for quick, no-oven crafting while polymer clay offers greater durability after baking.

Popular Uses in Craft Projects

Cold porcelain is widely favored for creating delicate floral arrangements and intricate decorative figurines due to its smooth finish and ease of carving, making it ideal for detailed, lifelike craft projects. Polymer clay is popular in jewelry making, miniature sculptures, and textured craft pieces because of its durability and ability to be cured in a home oven, which ensures long-lasting results. Both materials offer versatility, but cold porcelain is preferred for lightweight, air-dried crafts, while polymer clay excels in projects requiring structural strength and vibrant color retention.

Choosing the Best Medium for Your Craft

Cold porcelain offers a lightweight, air-drying option ideal for delicate sculptures and intricate floral designs, while polymer clay requires baking and provides superior durability and vibrant color retention for detailed, long-lasting projects. Cold porcelain's smooth texture allows for fine detail work but is less water-resistant, making it better suited for indoor decorative crafts. Polymer clay's versatility and strength make it the preferred choice for jewelry, miniatures, and items needing extra resilience and polish.

Cold Porcelain vs Polymer Clay Infographic

productdif.com

productdif.com