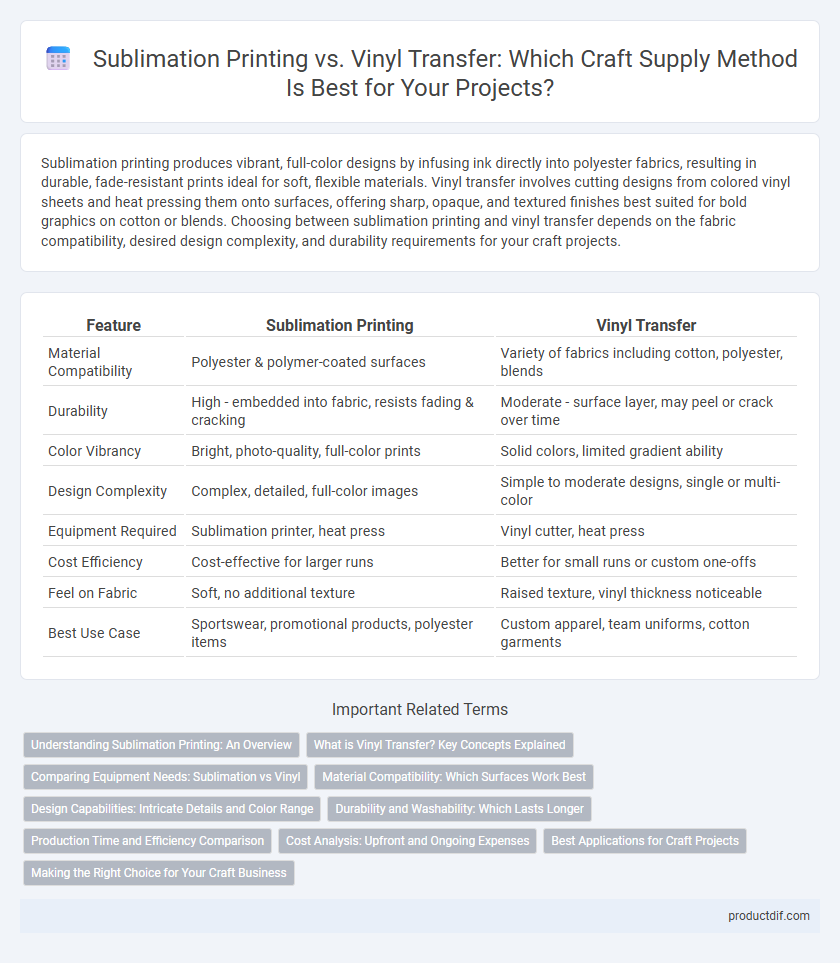

Sublimation printing produces vibrant, full-color designs by infusing ink directly into polyester fabrics, resulting in durable, fade-resistant prints ideal for soft, flexible materials. Vinyl transfer involves cutting designs from colored vinyl sheets and heat pressing them onto surfaces, offering sharp, opaque, and textured finishes best suited for bold graphics on cotton or blends. Choosing between sublimation printing and vinyl transfer depends on the fabric compatibility, desired design complexity, and durability requirements for your craft projects.

Table of Comparison

| Feature | Sublimation Printing | Vinyl Transfer |

|---|---|---|

| Material Compatibility | Polyester & polymer-coated surfaces | Variety of fabrics including cotton, polyester, blends |

| Durability | High - embedded into fabric, resists fading & cracking | Moderate - surface layer, may peel or crack over time |

| Color Vibrancy | Bright, photo-quality, full-color prints | Solid colors, limited gradient ability |

| Design Complexity | Complex, detailed, full-color images | Simple to moderate designs, single or multi-color |

| Equipment Required | Sublimation printer, heat press | Vinyl cutter, heat press |

| Cost Efficiency | Cost-effective for larger runs | Better for small runs or custom one-offs |

| Feel on Fabric | Soft, no additional texture | Raised texture, vinyl thickness noticeable |

| Best Use Case | Sportswear, promotional products, polyester items | Custom apparel, team uniforms, cotton garments |

Understanding Sublimation Printing: An Overview

Sublimation printing uses heat to transfer dye onto polyester or polymer-coated surfaces, resulting in vibrant, long-lasting images that become part of the material itself. This technique is ideal for producing detailed designs with a wide color spectrum and smooth gradients, especially on fabrics or hard surfaces like mugs and phone cases. Unlike vinyl transfer, sublimation offers greater durability and resistance to fading, making it perfect for personalized craft projects requiring high-quality, permanent prints.

What is Vinyl Transfer? Key Concepts Explained

Vinyl transfer is a popular craft supply technique involving cutting designs from colored or heat-transfer vinyl and applying them to fabrics or other surfaces using heat and pressure. This method offers durable, vibrant, and precise graphics ideal for custom apparel, home decor, and signage. Vinyl transfer is favored for its versatility, allowing intricate designs with solid colors or layers, unlike sublimation printing which works best on polyester fabrics with full-color gradients.

Comparing Equipment Needs: Sublimation vs Vinyl

Sublimation printing requires specialized heat presses capable of reaching high temperatures around 400degF and works best with polyester-coated substrates, whereas vinyl transfer primarily needs a heat press or an iron with moderate temperature settings near 300degF and standard vinyl cutters. Sublimation demands compatible printers with sublimation inks and transfer paper, while vinyl transfer setups involve cutting machines like Cricut or Silhouette for precision vinyl cutting. Maintenance and replacement costs are generally higher for sublimation equipment due to ink and printer upkeep, compared to the more affordable and versatile vinyl transfer machines.

Material Compatibility: Which Surfaces Work Best

Sublimation printing works best on polyester fabrics and specially coated hard surfaces like ceramics, metals, and glass, providing vibrant, durable colors that penetrate the material. Vinyl transfer excels on a wider range of textiles, including cotton, polyester blends, and dark or light fabrics, by applying heat and pressure to adhere the vinyl design. Understanding these material compatibilities helps crafters choose the ideal method for optimal durability and visual impact.

Design Capabilities: Intricate Details and Color Range

Sublimation printing offers superior design capabilities with vibrant, full-color prints and smooth gradients, ideal for intricate patterns and photographic images on polyester fabrics. Vinyl transfer excels in producing bold, solid colors with sharp edges, making it suitable for simple, high-contrast designs but limited in color blending and fine detail reproduction. Choosing between the two depends on the desired complexity and color depth of the craft project.

Durability and Washability: Which Lasts Longer

Sublimation printing bonds ink directly into polyester fibers, offering exceptional durability and washability without cracking or fading over time. Vinyl transfer applies a layer onto the fabric's surface, which can peel or crack after multiple washes, especially with frequent heat exposure. For long-lasting results on polyester garments, sublimation printing generally outperforms vinyl transfer in terms of maintaining vibrant colors and structural integrity after repeated laundering.

Production Time and Efficiency Comparison

Sublimation printing offers faster production times due to its direct-to-fabric process, eliminating the need for layered application, making it ideal for large runs with complex designs. Vinyl transfer requires precise cutting and layering of vinyl sheets, which increases setup time and is more labor-intensive, impacting efficiency for high-volume orders. Efficiency in sublimation is boosted by minimal drying or curing steps, while vinyl transfer demands additional heat pressing, slowing overall workflow.

Cost Analysis: Upfront and Ongoing Expenses

Sublimation printing requires a higher upfront investment due to the need for specialized printers and heat presses, while vinyl transfer typically demands lower initial costs with basic cutting machines and heat application tools. Ongoing expenses for sublimation include ink refills and sublimation paper, which can be more costly compared to vinyl sheets and transfer tapes used in vinyl transfer processes. Choosing between sublimation and vinyl transfer hinges on budget constraints, production volume, and material costs, with sublimation offering vibrant, long-lasting prints and vinyl providing cost-effective flexibility for short runs.

Best Applications for Craft Projects

Sublimation printing excels in creating vibrant, full-color designs on polyester fabrics and coated surfaces, making it ideal for custom apparel, home decor, and promotional items with complex images. Vinyl transfer is best suited for bold, single or multi-color designs on various fabrics, including cotton, and offers durability for personalized T-shirts, bags, and hats. Choosing between sublimation and vinyl depends on the material type and design complexity, ensuring high-quality, long-lasting craft projects.

Making the Right Choice for Your Craft Business

Sublimation printing offers vibrant, full-color designs with excellent durability on polyester fabrics, making it ideal for custom apparel and promotional items in your craft business. Vinyl transfer provides versatility with a wide range of colors and textures, allowing precise and durable designs on various materials including cotton, making it suitable for smaller runs and personalized projects. Understanding the substrate compatibility, design complexity, and production volume will help you make the right choice between sublimation printing and vinyl transfer to maximize quality and profitability.

Sublimation printing vs Vinyl transfer Infographic

productdif.com

productdif.com