Enamel pins offer a smooth, polished finish with vibrant colors that make intricate designs stand out, while resin pins provide a glossy, dome-shaped surface that adds depth and durability. Enamel pins are typically more affordable and lightweight, ideal for bulk orders and detailed artwork. Resin pins, with their protective coating, resist scratches and moisture, making them perfect for items that require extra longevity and a sleek, modern look.

Table of Comparison

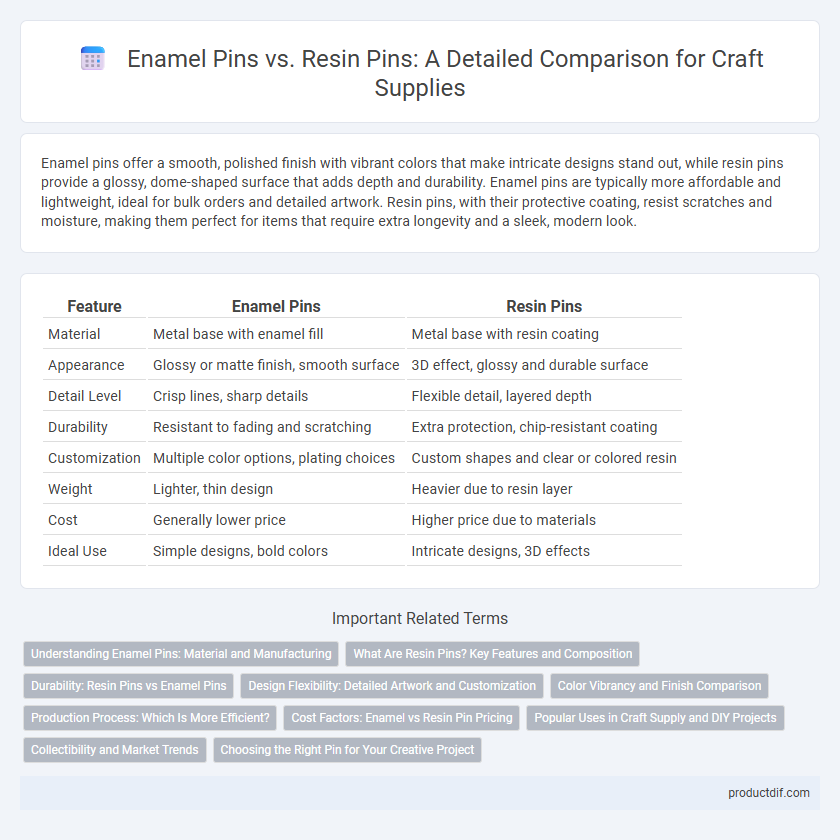

| Feature | Enamel Pins | Resin Pins |

|---|---|---|

| Material | Metal base with enamel fill | Metal base with resin coating |

| Appearance | Glossy or matte finish, smooth surface | 3D effect, glossy and durable surface |

| Detail Level | Crisp lines, sharp details | Flexible detail, layered depth |

| Durability | Resistant to fading and scratching | Extra protection, chip-resistant coating |

| Customization | Multiple color options, plating choices | Custom shapes and clear or colored resin |

| Weight | Lighter, thin design | Heavier due to resin layer |

| Cost | Generally lower price | Higher price due to materials |

| Ideal Use | Simple designs, bold colors | Intricate designs, 3D effects |

Understanding Enamel Pins: Material and Manufacturing

Enamel pins are crafted by filling recessed areas of metal blanks with powdered enamel that is baked at high temperatures, resulting in a durable, glossy finish with vibrant colors. The manufacturing process involves stamping or die-striking the metal base, often made from brass, iron, or copper, followed by careful enamel application and baking to harden. This method produces crisp, detailed designs with a smooth surface, making enamel pins popular for their quality and long-lasting appeal compared to resin pins.

What Are Resin Pins? Key Features and Composition

Resin pins are crafted by pouring a clear or colored epoxy resin into a mold, resulting in a smooth, glossy finish that enhances the design's depth and color vibrancy. These pins often feature a lightweight composition, excellent durability, and a glass-like surface that resists scratches and fading over time. Key features include customizable shapes, transparency options, and the ability to embed small objects or glitter within the resin for unique, textured effects.

Durability: Resin Pins vs Enamel Pins

Resin pins offer superior durability due to their protective clear coating that guards against scratches, chips, and fading, making them ideal for everyday wear. Enamel pins, while visually striking with their smooth, vibrant colors and metal outlines, are more prone to surface wear and chipping over time. For long-lasting resilience, resin pins maintain their appearance better under frequent handling and exposure to elements compared to enamel pins.

Design Flexibility: Detailed Artwork and Customization

Enamel pins offer sharp, vibrant colors with defined metal lines, ideal for classic and intricate designs, while resin pins provide a smooth, glossy finish that allows for seamless color blending and 3D effects. Customization options in enamel pins include various metal finishes and textures, whereas resin pins can incorporate mixed media elements and layered artwork for depth. Both types support detailed artwork, but resin pins excel in flexible design complexity and protective coating options.

Color Vibrancy and Finish Comparison

Enamel pins offer sharp color vibrancy with a smooth, glossy finish achieved through hard or soft enamel filling, creating distinct, vivid hues that stand out on fabric. Resin pins, coated with a clear epoxy layer, enhance color depth and provide a shiny, glass-like surface while preserving intricate details and adding durability. Choosing between enamel and resin pins depends on the desired finish texture and vibrancy, with enamel emphasizing bold, flat color and resin delivering enhanced shine and dimension.

Production Process: Which Is More Efficient?

Enamel pins undergo a stamping and plating process followed by filling recessed areas with colored enamel, which can extend production time due to multiple curing stages. Resin pins involve injecting a clear or colored resin over a metal base, streamlining production with fewer steps and faster curing times. Resin pin manufacturing tends to be more efficient for large orders, while enamel pins offer intricate detailing that may justify longer production durations.

Cost Factors: Enamel vs Resin Pin Pricing

Enamel pins generally have higher upfront costs due to complex manufacturing processes involving metal plating and hard or soft enamel filling, which require precision and durability. Resin pins often cost less because the resin overlay is applied after printing or stamping, reducing labor and material expenses while still providing a glossy finish. Pricing for enamel pins typically increases with intricate designs, whereas resin pins offer a budget-friendly alternative for vibrant, detailed artwork without metalwork costs.

Popular Uses in Craft Supply and DIY Projects

Enamel pins are popular in craft supply and DIY projects for their vibrant colors and durable, smooth finish, making them ideal for custom lapel pins, badges, and decorative accessories. Resin pins, favored for their glossy, three-dimensional appearance, are commonly used in personalized keychains, charms, and jewelry pieces that require a modern, polished look. Both types appeal to crafters seeking unique, high-quality embellishments that enhance handmade creations and small-batch product lines.

Collectibility and Market Trends

Enamel pins are highly sought after for their vibrant colors, precise detailing, and durability, making them a staple among collectors who value limited editions and artist collaborations. Resin pins, with their 3D designs and customizable textures, appeal to niche markets seeking unique tactile experiences and innovative aesthetics. Market trends indicate enamel pins dominate mainstream collectibility due to their traditional appeal and widespread availability, while resin pins are rapidly growing in popularity among enthusiasts prioritizing artistic creativity and exclusivity.

Choosing the Right Pin for Your Creative Project

Enamel pins offer a classic, durable finish with vibrant colors perfect for detailed designs and a professional look, making them ideal for collectors and brand promotions. Resin pins provide a glossy, smooth surface that protects intricate artwork beneath a clear coat, enhancing visual depth and making them suitable for colorful, custom art projects. Selecting between enamel and resin pins depends on your project's aesthetic needs, budget, and the desired texture or finish to best showcase your creative vision.

Enamel pins vs Resin pins Infographic

productdif.com

productdif.com