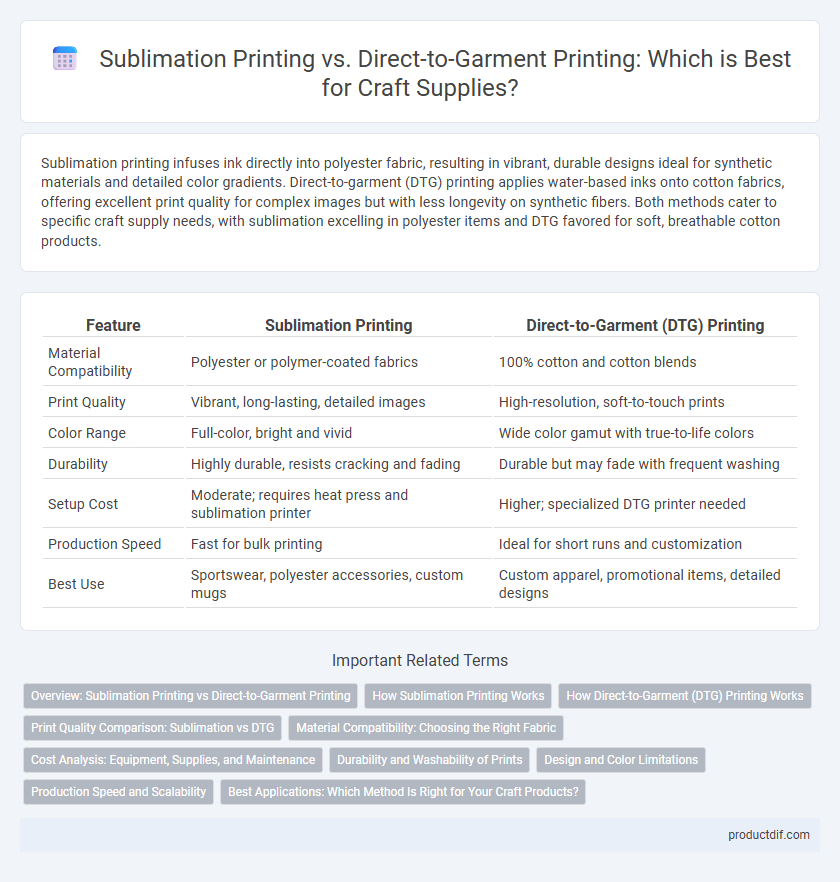

Sublimation printing infuses ink directly into polyester fabric, resulting in vibrant, durable designs ideal for synthetic materials and detailed color gradients. Direct-to-garment (DTG) printing applies water-based inks onto cotton fabrics, offering excellent print quality for complex images but with less longevity on synthetic fibers. Both methods cater to specific craft supply needs, with sublimation excelling in polyester items and DTG favored for soft, breathable cotton products.

Table of Comparison

| Feature | Sublimation Printing | Direct-to-Garment (DTG) Printing |

|---|---|---|

| Material Compatibility | Polyester or polymer-coated fabrics | 100% cotton and cotton blends |

| Print Quality | Vibrant, long-lasting, detailed images | High-resolution, soft-to-touch prints |

| Color Range | Full-color, bright and vivid | Wide color gamut with true-to-life colors |

| Durability | Highly durable, resists cracking and fading | Durable but may fade with frequent washing |

| Setup Cost | Moderate; requires heat press and sublimation printer | Higher; specialized DTG printer needed |

| Production Speed | Fast for bulk printing | Ideal for short runs and customization |

| Best Use | Sportswear, polyester accessories, custom mugs | Custom apparel, promotional items, detailed designs |

Overview: Sublimation Printing vs Direct-to-Garment Printing

Sublimation printing uses heat to transfer dye onto polyester fabrics, offering vibrant, durable, and full-color designs ideal for sportswear and polyester blends. Direct-to-garment (DTG) printing applies water-based inks directly onto cotton or natural fibers, producing soft, detailed prints suitable for complex, multi-color designs on t-shirts. Key differences include fabric compatibility, color vibrancy, and print durability, with sublimation excelling in polyester and longevity, while DTG provides versatility on cotton materials.

How Sublimation Printing Works

Sublimation printing uses heat to transfer dye onto polyester fabrics or polymer-coated substrates, converting solid dye into gas without passing through a liquid state. This process enables vibrant, long-lasting, and fade-resistant prints that become part of the fabric itself. Ideal for all-over prints and detailed images, sublimation works best on light-colored synthetic materials, distinguishing it from direct-to-garment printing, which deposits ink on natural fibers.

How Direct-to-Garment (DTG) Printing Works

Direct-to-Garment (DTG) printing uses specialized inkjet technology to apply water-based inks directly onto textiles, allowing for high-resolution, full-color designs with fine details. The process involves pre-treating the fabric to ensure ink adherence and then curing the print with heat to set the design, resulting in vibrant, durable prints ideal for cotton garments. DTG printing excels in small-batch production and customization due to its minimal setup time and ability to print complex images without screens or plates.

Print Quality Comparison: Sublimation vs DTG

Sublimation printing offers vibrant, permanent color with excellent durability on polyester fabrics, delivering sharp, high-resolution images that resist fading and cracking. Direct-to-garment printing provides greater versatility on cotton and dark fabrics, producing detailed, soft-to-the-touch prints but may experience slight fading after multiple washes. For superior print quality on synthetic materials, sublimation excels, whereas DTG is preferred for natural fibers with detailed color gradients.

Material Compatibility: Choosing the Right Fabric

Sublimation printing works best on polyester or polyester-coated materials because the ink bonds with synthetic fibers, producing vibrant, durable colors. Direct-to-garment (DTG) printing is compatible with 100% cotton or cotton blends, allowing for soft, detailed prints but may not be suitable for synthetic fabrics. Selecting the right fabric ensures optimal print quality, color longevity, and overall craftsmanship in your projects.

Cost Analysis: Equipment, Supplies, and Maintenance

Sublimation printing requires investment in specialized heat presses and dye-sublimation printers, with relatively low-cost sublimation inks and transfer papers, leading to moderate ongoing supply expenses. Direct-to-garment (DTG) printing demands higher upfront costs for advanced DTG printers and specialized textile inks, with increased maintenance due to frequent printhead cleanings and ink cartridge replacements. Considering total cost of ownership, sublimation printing often provides a more economical option for polyester fabrics, while DTG excels in versatility but incurs higher equipment and upkeep costs.

Durability and Washability of Prints

Sublimation printing offers exceptional durability and washability by embedding the ink directly into polyester fibers, maintaining vibrant colors even after multiple washes without fading or cracking. Direct-to-garment (DTG) printing, while providing detailed and colorful prints on cotton fabrics, tends to show signs of wear such as fading and cracking after repeated laundering. For long-lasting and highly washable craft projects, sublimation printing on polyester substrates stands out as the superior choice.

Design and Color Limitations

Sublimation printing excels in vibrant, full-color designs with unlimited color options, making it ideal for complex, photo-realistic images on polyester fabrics. Direct-to-garment printing supports a broad color spectrum but may struggle with color accuracy and vibrancy on darker garments, limiting design choices. Both methods have distinct constraints: sublimation is restricted to light-colored polyester, while DTG works on cotton but may not capture fine details as vividly.

Production Speed and Scalability

Sublimation printing offers faster production speeds for large orders due to its efficient heat transfer process, making it ideal for scalable runs on polyester fabrics. Direct-to-garment (DTG) printing, while slower per unit, allows for quick turnaround on small batches and complex designs without setup time, favoring customization. Production scalability in sublimation excels with volume consistency, whereas DTG provides flexibility and reduces inventory risks for varied designs.

Best Applications: Which Method Is Right for Your Craft Products?

Sublimation printing excels in vibrant, full-color designs on polyester fabrics and hard surfaces, making it ideal for custom mugs, phone cases, and sportswear with intricate artwork. Direct-to-garment (DTG) printing works best on 100% cotton apparel, providing soft, detailed prints perfect for t-shirts, hoodies, and small-batch clothing with complex color gradients. Selecting the right method depends on your product material and design complexity, with sublimation offering durability for coated items and DTG delivering versatility on natural fibers.

Sublimation printing vs Direct-to-garment printing Infographic

productdif.com

productdif.com