Laser cutting offers precise and consistent results with intricate designs, making it ideal for detailed craft projects involving pet supplies. Hand cutting provides greater control and customization for unique, small-batch items but requires more time and skill. Choosing between laser cutting and hand cutting depends on the desired accuracy, production volume, and complexity of pet craft materials.

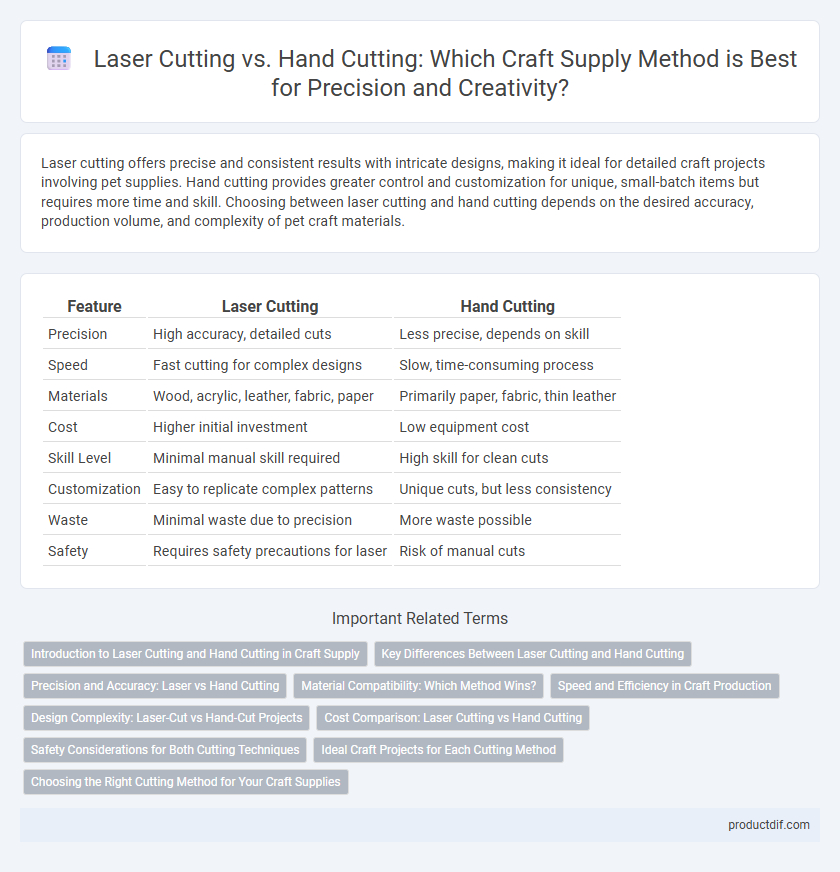

Table of Comparison

| Feature | Laser Cutting | Hand Cutting |

|---|---|---|

| Precision | High accuracy, detailed cuts | Less precise, depends on skill |

| Speed | Fast cutting for complex designs | Slow, time-consuming process |

| Materials | Wood, acrylic, leather, fabric, paper | Primarily paper, fabric, thin leather |

| Cost | Higher initial investment | Low equipment cost |

| Skill Level | Minimal manual skill required | High skill for clean cuts |

| Customization | Easy to replicate complex patterns | Unique cuts, but less consistency |

| Waste | Minimal waste due to precision | More waste possible |

| Safety | Requires safety precautions for laser | Risk of manual cuts |

Introduction to Laser Cutting and Hand Cutting in Craft Supply

Laser cutting in craft supply uses precise, computer-controlled lasers to cut intricate designs from materials like wood, acrylic, and fabric, offering high accuracy and speed. Hand cutting relies on manual tools such as scissors, craft knives, and rotary cutters, providing flexibility and tactile control for small-scale or detailed projects. Both methods serve essential roles, with laser cutting excelling in complex patterns and mass production, while hand cutting supports customization and delicate craftsmanship.

Key Differences Between Laser Cutting and Hand Cutting

Laser cutting offers precision and speed by using a focused light beam to cut materials with clean edges and intricate designs, ideal for complex craft projects. Hand cutting relies on manual tools like scissors or knives, providing tactile control but often resulting in less accuracy and slower production. Key differences include the level of detail achievable, consistency of cuts, and time efficiency, making laser cutting preferable for repetitive or detailed tasks while hand cutting suits simpler, custom adjustments.

Precision and Accuracy: Laser vs Hand Cutting

Laser cutting offers exceptional precision and accuracy, achieving intricate designs with clean, consistent edges down to fractions of a millimeter. Hand cutting, while versatile, often results in slight variations and less sharpness due to human error and tool limitations. For crafts requiring detailed patterns and repeatable accuracy, laser cutting provides superior results compared to manual methods.

Material Compatibility: Which Method Wins?

Laser cutting offers superior material compatibility, effortlessly handling wood, acrylic, leather, and fabric with precise, clean edges. Hand cutting works well for softer materials like paper and thin fabrics but struggles with tougher or thicker surfaces, often resulting in uneven cuts. For versatility and professional-quality finishes, laser cutting is the preferred method.

Speed and Efficiency in Craft Production

Laser cutting offers unparalleled speed and precision in craft production by quickly slicing through materials with minimal errors, significantly outpacing hand cutting methods. Automated laser systems efficiently reproduce intricate designs, reducing labor time and ensuring consistent results in large or complex batches. Hand cutting, while offering tactile control for unique or delicate tasks, generally requires more time and effort, making it less efficient for high-volume production.

Design Complexity: Laser-Cut vs Hand-Cut Projects

Laser cutting enables intricate and highly detailed designs with precision accuracy, making it ideal for complex patterns and fine details that are difficult to achieve by hand. Hand cutting offers greater control over organic shapes and unique imperfections, providing a personalized touch but often limiting the complexity and uniformity of the design. Projects requiring consistent, elaborate designs benefit significantly from laser cutting, while simpler or one-of-a-kind pieces may still favor hand cutting techniques.

Cost Comparison: Laser Cutting vs Hand Cutting

Laser cutting offers precise, consistent cuts with minimal material waste, making it cost-effective for large-scale or intricate craft supply projects despite higher initial equipment investment. Hand cutting requires lower upfront costs but increases labor time and material loss, often resulting in higher per-piece expense for complex designs. For businesses prioritizing scalability and accuracy, laser cutting provides better long-term cost efficiency compared to hand cutting.

Safety Considerations for Both Cutting Techniques

Laser cutting offers precision and speed but requires strict safety measures such as proper ventilation to avoid inhaling harmful fumes and protective eyewear to prevent eye damage from intense laser beams. Hand cutting minimizes exposure to hazardous emissions but carries risks of physical injuries like cuts and repetitive strain, necessitating the use of gloves, cutting mats, and ergonomic tools. Both techniques demand adherence to safety standards and regular maintenance of equipment to ensure a secure crafting environment.

Ideal Craft Projects for Each Cutting Method

Laser cutting excels in precision and intricate designs, making it ideal for projects like detailed stencils, personalized jewelry, and intricate woodwork where accuracy is paramount. Hand cutting suits simpler, tactile crafts such as fabric applique, scrapbooking, and leatherwork, where manual control and flexibility enhance creative expression. Selecting the cutting method depends on the complexity and material of the craft project, with laser cutting preferred for fine detail and hand cutting favored for customizable, hands-on tasks.

Choosing the Right Cutting Method for Your Craft Supplies

Laser cutting offers unmatched precision for intricate designs on materials like wood, acrylic, and fabric, making it ideal for detailed craft projects. Hand cutting allows greater control and flexibility for small-scale or customized pieces, especially with softer materials such as paper and felt. Selecting the right cutting method depends on material type, design complexity, and production volume to ensure efficiency and desired quality in your craft supplies.

Laser Cutting vs Hand Cutting Infographic

productdif.com

productdif.com