Silkscreen printing offers precise, detailed designs ideal for intricate craft projects, while block printing provides a textured, handmade feel perfect for rustic pet accessories. Silkscreen techniques use a mesh stencil to apply ink evenly, ensuring vibrant and consistent patterns. Block printing involves carving designs into a block, creating unique, customizable prints with each impression.

Table of Comparison

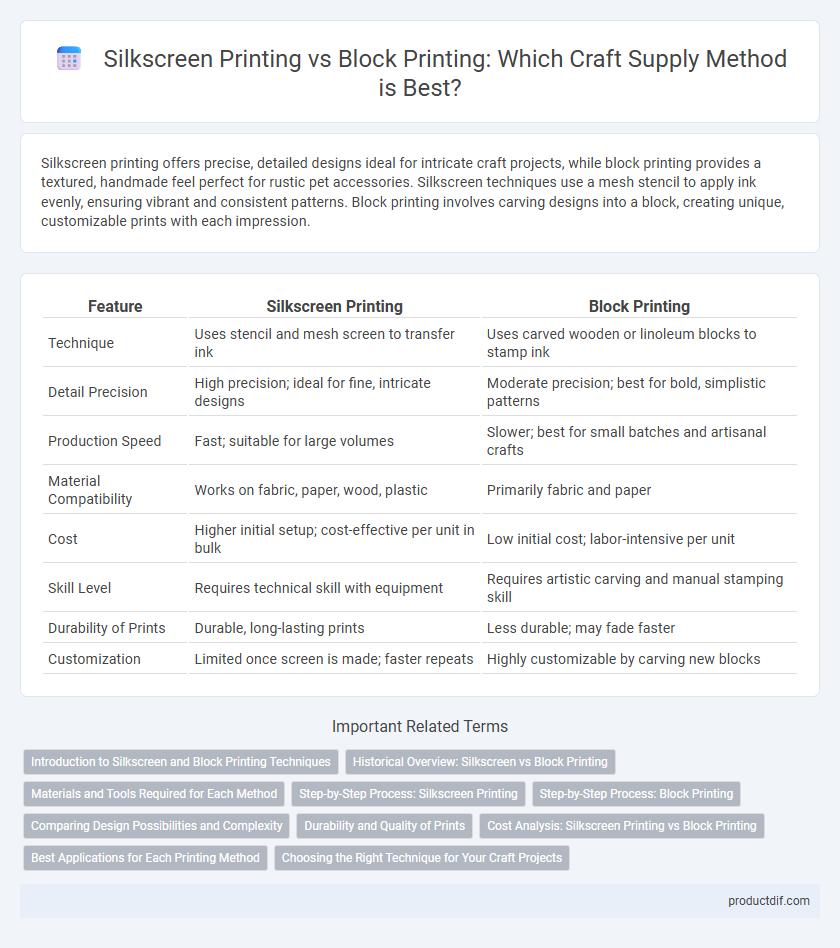

| Feature | Silkscreen Printing | Block Printing |

|---|---|---|

| Technique | Uses stencil and mesh screen to transfer ink | Uses carved wooden or linoleum blocks to stamp ink |

| Detail Precision | High precision; ideal for fine, intricate designs | Moderate precision; best for bold, simplistic patterns |

| Production Speed | Fast; suitable for large volumes | Slower; best for small batches and artisanal crafts |

| Material Compatibility | Works on fabric, paper, wood, plastic | Primarily fabric and paper |

| Cost | Higher initial setup; cost-effective per unit in bulk | Low initial cost; labor-intensive per unit |

| Skill Level | Requires technical skill with equipment | Requires artistic carving and manual stamping skill |

| Durability of Prints | Durable, long-lasting prints | Less durable; may fade faster |

| Customization | Limited once screen is made; faster repeats | Highly customizable by carving new blocks |

Introduction to Silkscreen and Block Printing Techniques

Silkscreen printing involves forcing ink through a fine mesh stencil to create detailed, vibrant designs on various surfaces, making it ideal for mass production and precision. Block printing, an ancient technique, uses carved wooden or linoleum blocks to stamp inked patterns onto fabric or paper, offering a handmade, textured aesthetic. Both methods offer unique artistic styles, with silkscreen emphasizing clarity and replication while block printing highlights craftsmanship and organic irregularities.

Historical Overview: Silkscreen vs Block Printing

Silkscreen printing originated in ancient China and was refined in Japan, gaining commercial popularity in the early 20th century for its versatility in producing vibrant, detailed images. Block printing dates back to ancient Mesopotamia and Egypt, with carved wooden blocks being used for textile and paper printing, flourishing especially in India and China for centuries. Both methods have rich cultural heritages, with block printing emphasizing hand-carving techniques and silkscreen printing utilizing stencils and mesh screens for intricate designs.

Materials and Tools Required for Each Method

Silkscreen printing requires a mesh screen, squeegee, stencil, and specialized inks designed for fabric or paper, allowing for precise and repeatable designs. Block printing involves carved wooden or linoleum blocks, fabric or paper, and thick, slow-drying inks or paints suitable for manual application. Both methods demand unique tools and ink types that influence the texture, detail, and versatility of the final print.

Step-by-Step Process: Silkscreen Printing

Silkscreen printing involves creating a stencil on a fine mesh screen, applying ink through the mesh onto the fabric or paper. Each color in the design requires a separate screen, with ink pushed through using a squeegee to achieve precise, vibrant layers. This method allows for high detail and repeatability, making it ideal for complex, multi-color craft projects.

Step-by-Step Process: Block Printing

Block printing involves carving a design into a wooden or linoleum block, applying ink evenly on the raised surfaces, and pressing the block firmly onto fabric or paper to transfer the pattern. Each color requires a separate block, and precise alignment, or registration, ensures consistent multi-color designs during the layering process. The technique demands drying time between prints to prevent smudging and allows artisans to create intricate, repeatable motifs with a tactile, handmade quality.

Comparing Design Possibilities and Complexity

Silkscreen printing offers high precision and the ability to produce intricate, multi-colored designs with smooth gradients, making it ideal for detailed and complex artwork. Block printing, while limited by the physical carving of blocks, provides a unique handmade texture and charm but restricts the intricacy and color variety due to layer-by-layer stamping. The design possibilities in silkscreen printing are broader and more versatile, whereas block printing emphasizes simplicity and tactile variation in craft supplies.

Durability and Quality of Prints

Silkscreen printing produces highly durable prints with vibrant colors and sharp details, making it ideal for long-lasting craft projects. Block printing offers a unique handmade quality with distinct textures but often results in less precise and less durable designs compared to silkscreen. Choosing between the two depends on whether the priority is on print longevity and color richness or on artisanal authenticity and texture variation.

Cost Analysis: Silkscreen Printing vs Block Printing

Silkscreen printing requires an initial investment in screens and equipment, making it more cost-effective for large-volume production due to lower per-unit costs. Block printing has lower upfront expenses but higher labor costs and longer production times, which increase costs for large batches. For small runs or custom designs, block printing offers affordable setup costs, while silkscreen printing benefits bulk orders with reduced material waste and faster processing.

Best Applications for Each Printing Method

Silkscreen printing excels in producing vibrant, detailed designs on fabrics, posters, and promotional materials, making it ideal for large-scale, multi-color projects requiring high precision. Block printing is best suited for smaller runs and artisanal craft items such as custom stationery, home decor, and fabric with repetitive patterns, offering a handcrafted aesthetic and textured finish. Choosing silkscreen printing benefits commercial applications demanding durability and sharpness, while block printing is preferred for unique, limited-edition creations that emphasize traditional techniques.

Choosing the Right Technique for Your Craft Projects

Silkscreen printing offers precise, vibrant designs ideal for detailed and multi-colored craft projects, while block printing provides a traditional, textured look suited for simple patterns and repetitive motifs. Choosing the right technique depends on your project's complexity, desired aesthetic, and material compatibility, with silkscreen excelling on fabrics and paper, and block printing favored for handmade or rustic effects. Consider factors like production volume, cost, and skill level to ensure your craft project achieves the intended visual impact and durability.

Silkscreen Printing vs Block Printing Infographic

productdif.com

productdif.com