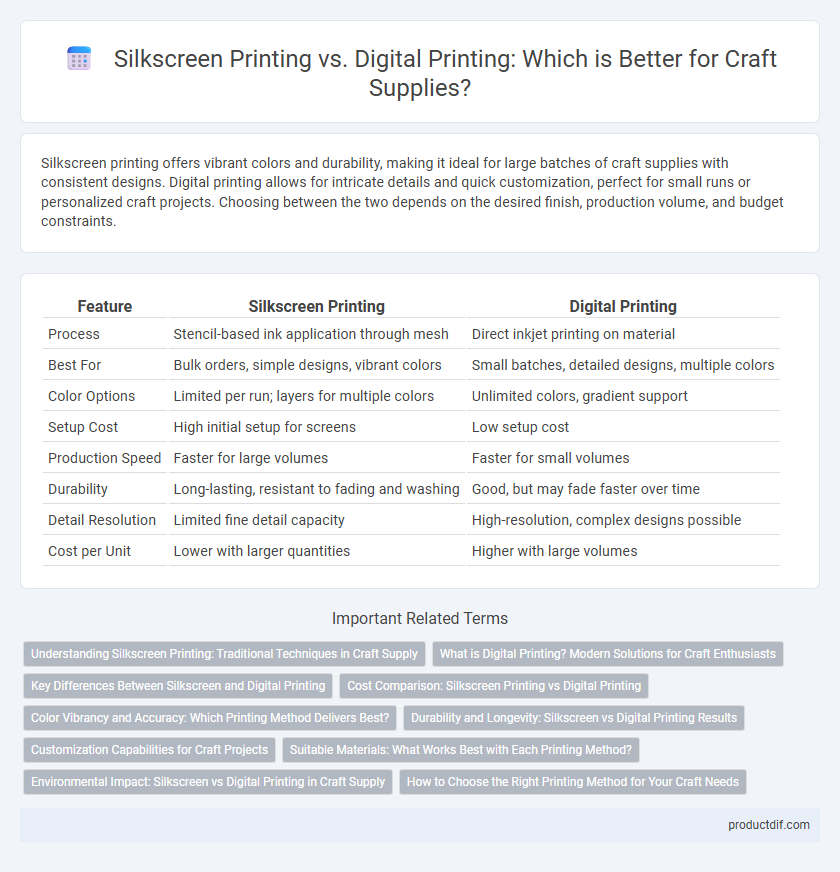

Silkscreen printing offers vibrant colors and durability, making it ideal for large batches of craft supplies with consistent designs. Digital printing allows for intricate details and quick customization, perfect for small runs or personalized craft projects. Choosing between the two depends on the desired finish, production volume, and budget constraints.

Table of Comparison

| Feature | Silkscreen Printing | Digital Printing |

|---|---|---|

| Process | Stencil-based ink application through mesh | Direct inkjet printing on material |

| Best For | Bulk orders, simple designs, vibrant colors | Small batches, detailed designs, multiple colors |

| Color Options | Limited per run; layers for multiple colors | Unlimited colors, gradient support |

| Setup Cost | High initial setup for screens | Low setup cost |

| Production Speed | Faster for large volumes | Faster for small volumes |

| Durability | Long-lasting, resistant to fading and washing | Good, but may fade faster over time |

| Detail Resolution | Limited fine detail capacity | High-resolution, complex designs possible |

| Cost per Unit | Lower with larger quantities | Higher with large volumes |

Understanding Silkscreen Printing: Traditional Techniques in Craft Supply

Silkscreen printing utilizes a mesh stencil to transfer ink onto various craft materials, offering vibrant colors and superior durability compared to digital printing. This traditional technique allows for precise layer-by-layer color application, making it ideal for bulk production of custom designs on textiles, paper, and wood. Understanding the meticulous setup of silkscreen frames and the selection of inks ensures optimal results in craft supply projects focused on high-quality, long-lasting prints.

What is Digital Printing? Modern Solutions for Craft Enthusiasts

Digital printing uses advanced inkjet or laser technology to transfer designs directly onto various craft materials with high precision and vibrant color accuracy. This method allows for easy customization, quick turnaround times, and detailed prints without the need for screens or plates, making it ideal for small batches and intricate designs. Modern digital printers support a wide range of substrates including fabric, wood, paper, and plastic, providing craft enthusiasts with versatile solutions for personalized projects.

Key Differences Between Silkscreen and Digital Printing

Silkscreen printing uses a stencil and ink pressed through a mesh screen, offering vibrant colors and durability ideal for bulk orders or large designs on various surfaces. Digital printing, on the other hand, involves directly transferring a digital image onto substrates using inkjet or laser technology, excelling in detailed images and small runs with faster turnaround times. Key differences include silkscreen's cost-efficiency for high-volume production and its limited color range versus digital printing's flexibility in color complexity and design customization.

Cost Comparison: Silkscreen Printing vs Digital Printing

Silkscreen printing generally involves higher upfront costs due to the creation of custom screens, making it more cost-effective for large volume orders where per-unit cost decreases significantly. Digital printing has lower initial costs as it requires no screens, which benefits small batch or one-off projects despite higher per-unit expenses. Overall, silkscreen printing offers better cost efficiency for bulk runs, while digital printing provides flexibility and affordability for limited quantities.

Color Vibrancy and Accuracy: Which Printing Method Delivers Best?

Silkscreen printing excels in color vibrancy by using thick layers of ink that create bold, rich hues, making it ideal for designs needing intense saturation. Digital printing offers higher color accuracy with precise, detailed reproductions and a broader color spectrum, especially for complex gradients and photographic images. For projects demanding maximum color vibrancy, silkscreen printing is preferred, while digital printing is superior when color precision and fine details are crucial.

Durability and Longevity: Silkscreen vs Digital Printing Results

Silkscreen printing offers superior durability and longevity due to its thick layers of ink that withstand wear, washing, and fading over time, making it ideal for long-lasting craft projects. Digital printing, while providing high-resolution, detailed images, tends to have a shorter lifespan with inks that may fade or crack after repeated use and exposure. Choosing silkscreen printing ensures vibrant, enduring designs especially suited for items subjected to frequent handling or outdoor conditions.

Customization Capabilities for Craft Projects

Silkscreen printing excels in producing vibrant and durable designs with precise color layering, ideal for bulk craft projects requiring consistent customization. Digital printing offers unparalleled flexibility in detail and color variation, enabling complex and photo-quality images tailored for unique, small-batch crafts. Both methods provide distinct customization advantages, where silkscreen suits repetitive patterns and digital printing supports intricate, one-of-a-kind designs.

Suitable Materials: What Works Best with Each Printing Method?

Silkscreen printing is ideal for materials like cotton, polyester, and other natural or synthetic fabrics, as well as paper and wood, providing vibrant colors and durability. Digital printing works best with smooth surfaces such as polyester blends, canvas, and coated papers, enabling detailed and multicolor designs with a softer feel. Choosing the right material depends on the print's intended use, durability requirements, and color complexity.

Environmental Impact: Silkscreen vs Digital Printing in Craft Supply

Silkscreen printing in craft supply generates more waste due to stencil materials and chemical use, leading to higher environmental impact compared to digital printing. Digital printing reduces waste with precise ink application and minimal water usage, making it a more eco-friendly option. Both methods require consideration of ink types, but water-based digital inks typically offer lower toxicity and environmental hazards.

How to Choose the Right Printing Method for Your Craft Needs

Silkscreen printing offers vibrant colors and durability, making it ideal for bulk orders and textured designs, while digital printing excels in capturing intricate details and color gradients perfect for small runs and customized crafts. Consider factors like project volume, design complexity, budget, and material type to determine the best printing method for your specific craft needs. Selecting the right method ensures optimal print quality, cost-effectiveness, and overall satisfaction with your crafting project.

Silkscreen Printing vs Digital Printing Infographic

productdif.com

productdif.com