Laser-cut wood offers precise, intricate designs with consistent quality and faster production times compared to hand-cut wood, which provides a unique, artisanal touch and subtle variations in each piece. Crafts utilizing laser-cut wood benefit from high accuracy ideal for detailed patterns, while hand-cut wood adds character and a personalized aesthetic valued in bespoke projects. Choosing between laser-cut and hand-cut wood depends on the desired balance of precision and handcrafted authenticity in craft supplies.

Table of Comparison

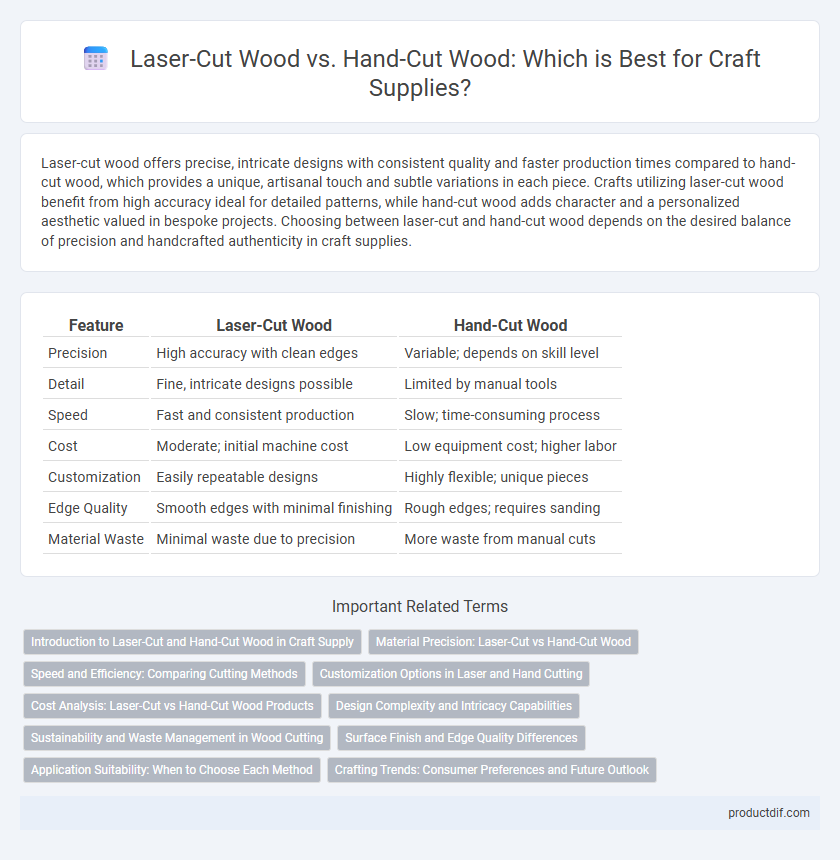

| Feature | Laser-Cut Wood | Hand-Cut Wood |

|---|---|---|

| Precision | High accuracy with clean edges | Variable; depends on skill level |

| Detail | Fine, intricate designs possible | Limited by manual tools |

| Speed | Fast and consistent production | Slow; time-consuming process |

| Cost | Moderate; initial machine cost | Low equipment cost; higher labor |

| Customization | Easily repeatable designs | Highly flexible; unique pieces |

| Edge Quality | Smooth edges with minimal finishing | Rough edges; requires sanding |

| Material Waste | Minimal waste due to precision | More waste from manual cuts |

Introduction to Laser-Cut and Hand-Cut Wood in Craft Supply

Laser-cut wood in craft supply offers precise, detailed cuts achieved through advanced computer-controlled technology, enabling intricate designs and consistent quality ideal for complex projects. Hand-cut wood involves manual shaping and cutting using traditional tools, providing a unique, artisanal touch with slight variations that emphasize craftsmanship and authenticity. Both methods cater to different crafting needs, where laser-cutting excels in precision and speed, while hand-cutting delivers personalized, rustic aesthetics.

Material Precision: Laser-Cut vs Hand-Cut Wood

Laser-cut wood offers superior material precision with intricate designs and consistent cuts down to fractions of a millimeter, ideal for detailed craft projects. Hand-cut wood, while possessing a unique artisanal quality, often exhibits slight variations and less uniformity due to manual cutting techniques. Precision laser cutting reduces material waste and speeds up production compared to the more time-consuming, variable hand-cutting process.

Speed and Efficiency: Comparing Cutting Methods

Laser-cut wood offers significantly faster cutting speeds and higher precision compared to hand-cut wood, reducing production time and material waste. Hand-cut wood requires skilled labor and is slower, making it less efficient for large-scale projects but ideal for detailed, customizable designs. The automation in laser cutting enhances consistency and scalability, optimizing workflow in craft supply businesses.

Customization Options in Laser and Hand Cutting

Laser-cut wood offers highly precise customization options with intricate designs and fine details achievable through computer-controlled technology. Hand-cut wood allows for more organic, unique shapes but may lack the uniformity and repeatability of laser cuts. Both methods provide customization, yet laser cutting excels in speed, accuracy, and complexity for craft supply projects.

Cost Analysis: Laser-Cut vs Hand-Cut Wood Products

Laser-cut wood typically incurs higher upfront equipment costs but offers faster production and consistent precision, reducing labor expenses over time. Hand-cut wood requires minimal initial investment but demands more intensive manual labor, increasing time costs and variability in product quality. Evaluating cost efficiency depends on production volume and the balance between automation benefits and craftsmanship value.

Design Complexity and Intricacy Capabilities

Laser-cut wood enables unparalleled design complexity and intricacy, producing precise, detailed cuts that capture fine patterns and delicate shapes with high accuracy. Hand-cut wood offers a more organic, artisanal quality but is limited in replicating extremely intricate designs consistently. The precision of laser cutting outperforms traditional hand-cutting, especially for complex geometric and intricate decorative elements in craft projects.

Sustainability and Waste Management in Wood Cutting

Laser-cut wood offers higher precision, reducing material wastage and enabling more efficient use of raw timber compared to hand-cut wood. The controlled nature of laser cutting minimizes offcuts and errors, supporting sustainable forestry practices by maximizing yield from each piece. Hand-cut wood often generates irregular scraps, posing challenges in waste management and lowering overall sustainability in craft supply chains.

Surface Finish and Edge Quality Differences

Laser-cut wood offers precise, smooth edges with minimal splintering due to its controlled heat application, resulting in a clean surface finish ideal for intricate designs. Hand-cut wood exhibits more natural, textured edges with potential minor imperfections and a rougher surface finish, reflecting traditional craftsmanship and authenticity. Both methods impact the final product's aesthetic, with laser cutting favoring uniformity and hand cutting emphasizing artisanal character.

Application Suitability: When to Choose Each Method

Laser-cut wood excels in intricate designs requiring high precision, making it ideal for detailed jewelry, architectural models, and decorative art projects. Hand-cut wood remains preferable for rustic or organic styles, where the craftsmanship and natural variation add unique character, such as custom furniture or folk art. Choosing between laser-cut and hand-cut depends on the desired finish, project complexity, and whether precision or artisanal texture is prioritized.

Crafting Trends: Consumer Preferences and Future Outlook

Laser-cut wood offers precision and intricate designs favored by modern crafters prioritizing efficiency and consistency, while hand-cut wood appeals to those valuing traditional craftsmanship and unique, artisanal qualities. Current trends indicate a growing preference for laser-cut techniques in mass-produced craft supplies, driven by advancements in technology and demand for customizable products. Future outlook suggests a hybrid approach may dominate, combining digital precision with handcrafted touches to meet diverse consumer desires in the craft supply market.

Laser-cut wood vs Hand-cut wood Infographic

productdif.com

productdif.com