Resin casting offers a glossy, durable finish ideal for creating transparent or embedded designs, while polymer clay provides versatility with its moldable texture and vibrant color options. Resin requires precise mixing and curing times, making it suitable for detailed, high-gloss projects, whereas polymer clay can be shaped easily and baked at home, allowing for quick prototyping and customization. Choosing between resin casting and polymer clay depends on the desired texture, finish, and complexity of the craft project.

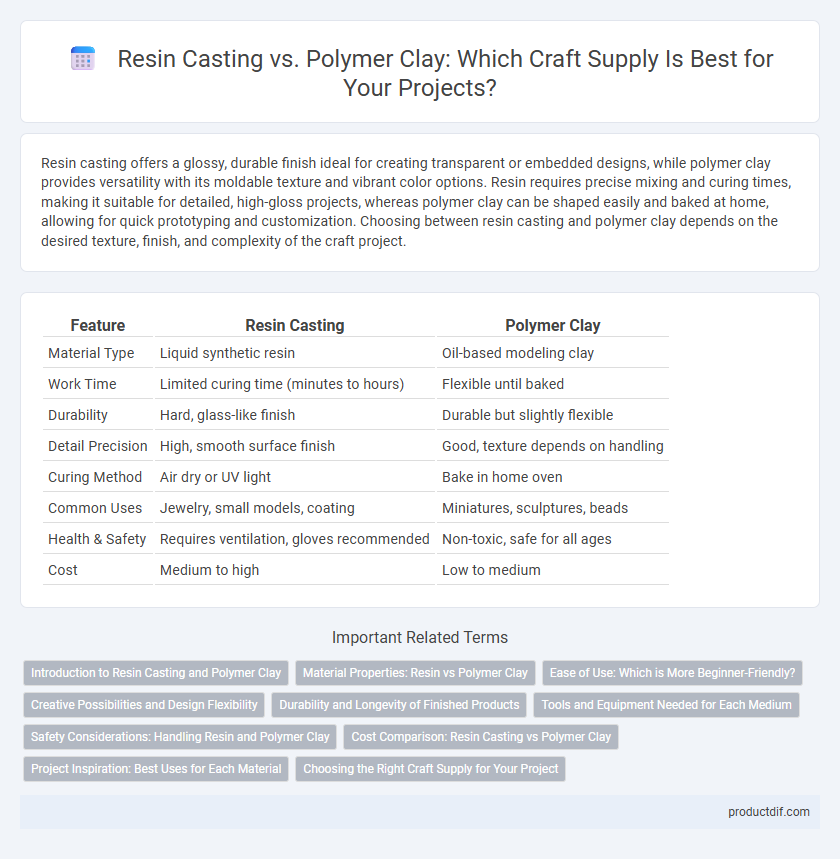

Table of Comparison

| Feature | Resin Casting | Polymer Clay |

|---|---|---|

| Material Type | Liquid synthetic resin | Oil-based modeling clay |

| Work Time | Limited curing time (minutes to hours) | Flexible until baked |

| Durability | Hard, glass-like finish | Durable but slightly flexible |

| Detail Precision | High, smooth surface finish | Good, texture depends on handling |

| Curing Method | Air dry or UV light | Bake in home oven |

| Common Uses | Jewelry, small models, coating | Miniatures, sculptures, beads |

| Health & Safety | Requires ventilation, gloves recommended | Non-toxic, safe for all ages |

| Cost | Medium to high | Low to medium |

Introduction to Resin Casting and Polymer Clay

Resin casting involves pouring liquid resin into molds where it hardens into solid, durable shapes, ideal for creating glossy, transparent, or colored finished pieces. Polymer clay is a malleable material that can be shaped by hand or tools and then baked to solidify into lightweight, flexible designs, offering vibrant color options and intricate detail. Both mediums are popular in craft supply projects, with resin casting delivering a polished, glass-like finish and polymer clay providing versatility for sculpting and detailed textures.

Material Properties: Resin vs Polymer Clay

Resin casting features a liquid thermosetting polymer that hardens into a durable, glossy, and transparent finish, making it ideal for detailed, high-strength projects. Polymer clay is a pliable, moldable material made from polyvinyl chloride (PVC) that hardens through baking, offering flexibility in texture and color blending but less durability compared to resin. Resin provides superior water resistance and hardness, while polymer clay excels in easy sculpting and vibrant, customizable finishes.

Ease of Use: Which is More Beginner-Friendly?

Resin casting offers smooth finishes and can create intricate, clear designs but requires precise mixing ratios and curing times, which may challenge beginners. Polymer clay is more beginner-friendly due to its malleability, forgiving nature in shaping, and straightforward baking process without the need for chemicals or prolonged waiting. For beginners prioritizing ease of use, polymer clay provides a simpler, less technical crafting experience.

Creative Possibilities and Design Flexibility

Resin casting offers exceptional clarity and durability, allowing artists to create intricate, translucent designs with embedded objects, enhancing creative possibilities in jewelry and decorative crafts. Polymer clay provides unmatched design flexibility through its blendability and malleability, enabling detailed sculpting, color mixing, and texturing for unique, handcrafted pieces. Both mediums cater to different artistic needs: resin excels in creating glossy, glass-like finishes, while polymer clay thrives in producing vibrant, tactile designs.

Durability and Longevity of Finished Products

Resin casting produces finished products with superior durability and resistance to wear, chemicals, and environmental factors compared to polymer clay. Polymer clay items, while versatile and easy to shape, tend to be more prone to chipping, cracking, and discoloration over time. For long-lasting craft supplies, resin casting offers enhanced longevity and structural integrity for detailed and durable creations.

Tools and Equipment Needed for Each Medium

Resin casting requires tools such as silicone molds, measuring cups, mixing sticks, gloves, and a well-ventilated workspace to safely handle and cure the resin. Polymer clay crafting involves basic tools like sculpting knives, clay blades, rollers, and an oven for baking the finished pieces. Both mediums demand precise tools tailored to their unique processes, with resin emphasizing safe mixing and curing equipment, while polymer clay relies on shaping instruments and controlled heat.

Safety Considerations: Handling Resin and Polymer Clay

Resin casting requires the use of gloves, masks, and well-ventilated spaces due to the presence of potentially harmful chemicals like epoxy resins and hardeners, which can cause skin irritation and respiratory issues. Polymer clay is generally safer to handle, but it must be baked at the correct temperature to avoid releasing toxic fumes, and users should avoid ingesting or inhaling dust from sanding uncured clay. Proper storage, usage, and disposal practices are essential to minimize health risks associated with both materials during crafting.

Cost Comparison: Resin Casting vs Polymer Clay

Resin casting often involves higher initial costs due to the price of resins, molds, and safety equipment, while polymer clay presents a more budget-friendly option with lower material and tool expenses. Although resin offers more durability and a professional finish, polymer clay is favored for its affordability and ease of use, especially for beginners or crafters working on small projects. Evaluating project scale and finish quality guides cost-effectiveness between resin casting and polymer clay mediums.

Project Inspiration: Best Uses for Each Material

Resin casting excels in creating clear, durable, and highly detailed jewelry pieces, keychains, and miniature sculptures due to its glossy finish and ability to capture intricate designs. Polymer clay is ideal for vibrant, tactile projects like custom figurines, beads, and textured art because it offers flexibility in shaping and color blending before baking. Choosing between resin casting and polymer clay depends on the desired project outcome, with resin favored for smooth, glass-like aesthetics and polymer clay preferred for colorful, moldable creations.

Choosing the Right Craft Supply for Your Project

Resin casting offers durability and a glass-like finish ideal for jewelry and detailed molds, while polymer clay provides versatility with easy sculpting and baking at home, perfect for vibrant, tactile creations. Selecting the right craft supply depends on project goals--opt for resin when seeking a smooth, glossy surface and lasting strength, or choose polymer clay for customizable shapes and quick prototyping. Understanding material properties such as curing times, flexibility, and finishing options ensures successful results tailored to your artistic vision.

Resin casting vs Polymer clay Infographic

productdif.com

productdif.com