Foam stamping offers a lightweight and flexible option ideal for creating large, bold impressions with vibrant color application, making it perfect for kids' crafts and quick projects. Rubber stamping provides detailed, sharp designs with durability suitable for intricate patterns and repeated use on various surfaces. Choosing between foam and rubber stamping depends on the desired level of detail, project scale, and material compatibility for crafting needs.

Table of Comparison

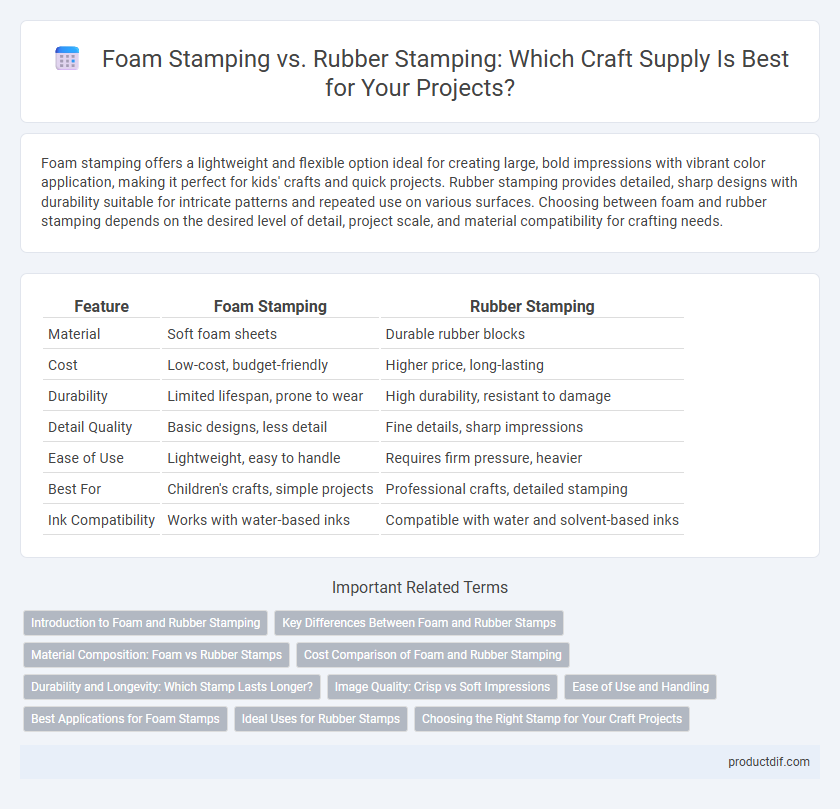

| Feature | Foam Stamping | Rubber Stamping |

|---|---|---|

| Material | Soft foam sheets | Durable rubber blocks |

| Cost | Low-cost, budget-friendly | Higher price, long-lasting |

| Durability | Limited lifespan, prone to wear | High durability, resistant to damage |

| Detail Quality | Basic designs, less detail | Fine details, sharp impressions |

| Ease of Use | Lightweight, easy to handle | Requires firm pressure, heavier |

| Best For | Children's crafts, simple projects | Professional crafts, detailed stamping |

| Ink Compatibility | Works with water-based inks | Compatible with water and solvent-based inks |

Introduction to Foam and Rubber Stamping

Foam stamping uses lightweight, flexible foam pads to create bold, textured impressions, ideal for vibrant, playful craft projects. Rubber stamping involves durable rubber blocks or sheets that deliver precise, detailed images with long-lasting ink adhesion, perfect for intricate designs and professional finishes. Both techniques offer unique tactile qualities, with foam providing softness and depth while rubber ensures sharpness and versatility in various craft applications.

Key Differences Between Foam and Rubber Stamps

Foam stamping offers lightweight, flexible impressions ideal for textured surfaces, while rubber stamping provides durable, precise, and detailed prints suitable for intricate designs. Foam stamps generally produce softer, less defined edges compared to rubber stamps, which maintain sharp clarity due to their dense material composition. The choice between foam and rubber stamps depends on the desired detail level, surface type, and frequency of use in craft projects.

Material Composition: Foam vs Rubber Stamps

Foam stamps consist of lightweight, flexible foam sheets bonded to a wooden or acrylic base, ideal for creating bold, textured impressions with ease. Rubber stamps are made from durable, high-quality vulcanized or photopolymer rubber, providing fine detail, longevity, and consistent ink absorption. The material composition directly impacts stamping clarity, with rubber offering precision and foam delivering softer, more playful prints.

Cost Comparison of Foam and Rubber Stamping

Foam stamping generally offers a lower upfront cost due to cheaper material and simpler production processes, making it ideal for short-term or low-volume craft projects. Rubber stamping, while having a higher initial investment because of durable, heat-cured rubber and metal mounting, provides longer-lasting stamps suitable for extensive use and intricate designs. Evaluating cost per impression, foam stamps may be more economical for limited runs, but rubber stamps deliver better value and consistency for repetitive crafting tasks.

Durability and Longevity: Which Stamp Lasts Longer?

Foam stamps typically have a shorter lifespan due to their softer material, which wears down faster with frequent use, while rubber stamps are renowned for their durability and ability to maintain sharp details over extended periods. Rubber stamps, especially those made from high-quality vulcanized rubber, resist cracking and deformation, ensuring consistent impressions even after thousands of prints. For crafters prioritizing longevity and repeated use, investing in rubber stamps offers superior durability compared to foam alternatives.

Image Quality: Crisp vs Soft Impressions

Foam stamping produces soft impressions with a textured, slightly blurred appearance ideal for playful or casual designs, while rubber stamping delivers crisp, sharp images perfect for detailed and precise artwork. The foam material's porous surface absorbs ink unevenly, resulting in a more diffused print compared to the firm, smooth surface of rubber stamps. For projects requiring high-definition lines and intricate details, rubber stamping is preferred, whereas foam stamping suits bold and expressive patterns.

Ease of Use and Handling

Foam stamping offers lightweight and flexible materials that are easier to handle, especially for beginners or children, compared to rubber stamping. Foam stamps require less pressure to create clear impressions, reducing hand fatigue during extended craft sessions. Rubber stamps provide durability and intricate detail but can be heavier and less maneuverable, making foam stamps a preferred choice for ease of use in casual or educational craft projects.

Best Applications for Foam Stamps

Foam stamping excels in creating bold, vibrant impressions on fabric, paper, and porous surfaces due to its softer material and ability to hold thick ink layers. Best applications for foam stamps include customizing T-shirts, scrapbooking, and card making where large, colorful designs are desired. Unlike rubber stamps, foam stamps provide a more forgiving and textured print, ideal for playful, child-friendly crafts and educational projects.

Ideal Uses for Rubber Stamps

Rubber stamps are ideal for detailed and durable impressions on paper, fabric, and wood, making them perfect for intricate craft projects, personalized stationery, and fabric decoration. Their flexibility allows for consistent, high-quality prints on uneven surfaces, enhancing the versatility for craft supply applications. Unlike foam stamps, rubber stamps offer greater precision and longevity, ideal for repetitive use in scrapbooking and card making.

Choosing the Right Stamp for Your Craft Projects

Foam stamping offers lightweight, flexible designs ideal for bold, easy-to-use impressions, making it perfect for children's crafts and large, simple patterns. Rubber stamping provides precise, detailed images with durability suitable for intricate artwork and professional-quality projects. Selecting the right stamp depends on project complexity, desired texture, and longevity, with foam stamps excelling in ease and rubber stamps in fine detail.

Foam stamping vs Rubber stamping Infographic

productdif.com

productdif.com