Cold process soap offers greater customization with natural ingredients and essential oils, allowing crafters to control texture and scent, while requiring a curing time of several weeks. Melt and pour soap provides convenience and speed, perfectly suited for beginners or quick projects, as it involves melting pre-made soap bases and adding colors or fragrances without waiting for curing. Choosing between the two methods depends on the desired level of creativity, time commitment, and ingredient control in crafting pet-safe soaps.

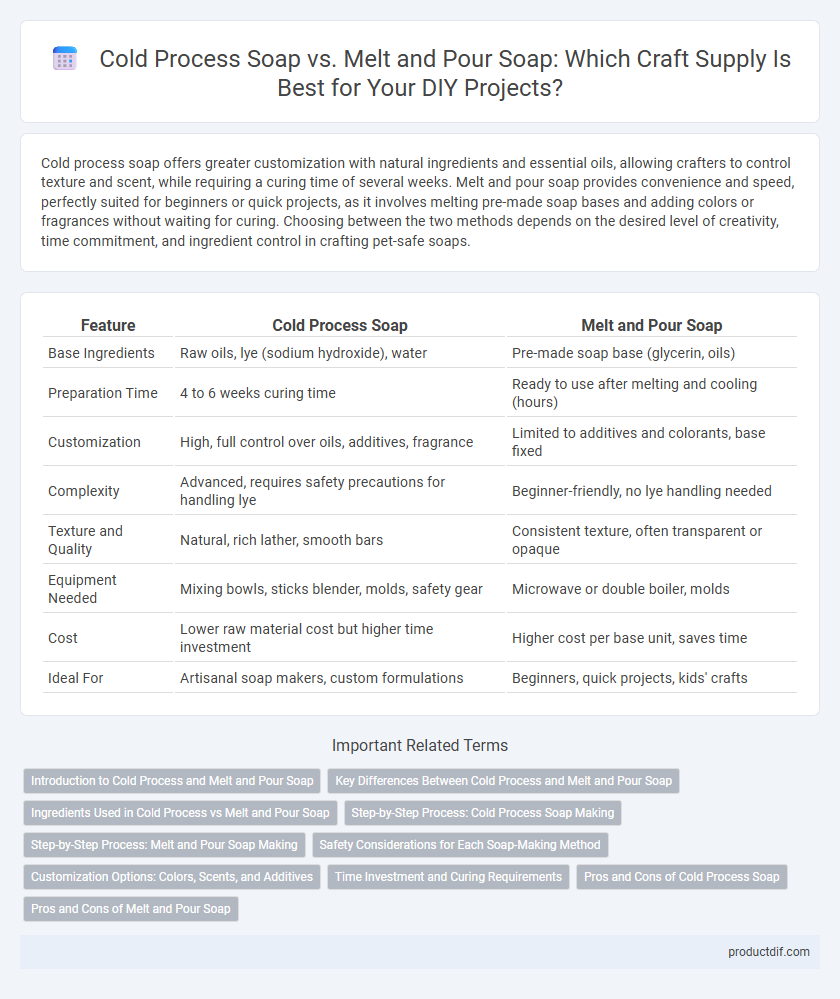

Table of Comparison

| Feature | Cold Process Soap | Melt and Pour Soap |

|---|---|---|

| Base Ingredients | Raw oils, lye (sodium hydroxide), water | Pre-made soap base (glycerin, oils) |

| Preparation Time | 4 to 6 weeks curing time | Ready to use after melting and cooling (hours) |

| Customization | High, full control over oils, additives, fragrance | Limited to additives and colorants, base fixed |

| Complexity | Advanced, requires safety precautions for handling lye | Beginner-friendly, no lye handling needed |

| Texture and Quality | Natural, rich lather, smooth bars | Consistent texture, often transparent or opaque |

| Equipment Needed | Mixing bowls, sticks blender, molds, safety gear | Microwave or double boiler, molds |

| Cost | Lower raw material cost but higher time investment | Higher cost per base unit, saves time |

| Ideal For | Artisanal soap makers, custom formulations | Beginners, quick projects, kids' crafts |

Introduction to Cold Process and Melt and Pour Soap

Cold process soap involves combining lye and oils to create a chemical reaction called saponification, resulting in a customizable, long-lasting bar with natural glycerin content. Melt and pour soap starts with a pre-made soap base that is melted, customized with colors or scents, and poured into molds, offering a quick, beginner-friendly craft option. Both methods provide unique advantages for soap crafters, but cold process requires precise measurements and curing time, while melt and pour allows immediate use.

Key Differences Between Cold Process and Melt and Pour Soap

Cold process soap involves mixing oils and lye to initiate saponification, resulting in a customizable bar with natural glycerin but requires curing time of 4-6 weeks. Melt and pour soap uses pre-made soap bases, melted and combined with additives, enabling quick production without lye handling and no curing time. Cold process offers greater flexibility for ingredients and textures, while melt and pour provides convenience and safety for beginners and small-scale crafters.

Ingredients Used in Cold Process vs Melt and Pour Soap

Cold process soap relies on natural oils or fats like olive oil, coconut oil, and lye (sodium hydroxide) to create soap through saponification, ensuring a customizable and skin-friendly product. Melt and pour soap utilizes pre-made glycerin soap bases, often enriched with additives such as colorants, fragrances, and moisturizers, eliminating the need for handling lye and reducing curing time. The ingredient control in cold process allows for tailored formulations, while melt and pour offers convenience and safety for beginner crafters.

Step-by-Step Process: Cold Process Soap Making

Cold process soap making involves combining lye (sodium hydroxide) with oils and butters, starting with carefully measuring and mixing the lye solution. The mixture is then blended until it reaches "trace," a custard-like consistency, before adding fragrances, colorants, and additives. Finally, the soap batter is poured into molds, insulated for 24-48 hours to saponify, then cured for 4-6 weeks to harden and mature.

Step-by-Step Process: Melt and Pour Soap Making

Melt and pour soap making involves melting a pre-made soap base using a double boiler or microwave, then adding fragrances, colorants, and additives before pouring the liquid into molds to cool and solidify. This method eliminates the need for handling lye, making it safer and more accessible for beginners compared to cold process soap. The simplicity and speed of melt and pour soap allow for customization and creativity with minimal preparation and curing time.

Safety Considerations for Each Soap-Making Method

Cold process soap requires careful handling of lye, a caustic substance that can cause burns and eye damage, making protective gear essential. Melt and pour soap eliminates direct contact with lye, significantly reducing safety risks and making it ideal for beginners and children. Proper ventilation and workspace hygiene remain important for both methods to prevent inhalation of fumes and maintain a safe crafting environment.

Customization Options: Colors, Scents, and Additives

Cold process soap offers extensive customization options, allowing crafters to incorporate natural colors from clays, herbs, and spices, along with essential oils and botanicals for unique scents and textures. Melt and pour soap provides convenience with premade bases, enabling easy addition of vibrant colorants, fragrance oils, and embeds such as dried flowers or exfoliants without curing time. Both methods support creative personalization, but cold process grants greater flexibility in ingredient control and formulation complexity.

Time Investment and Curing Requirements

Cold process soap requires a significant time investment, including a curing period of 4 to 6 weeks to allow the soap to harden and develop mildness. Melt and pour soap eliminates the curing phase, enabling immediate molding and use after cooling, which typically takes a few hours. The extended curing time of cold process soap enhances durability and lather quality, while melt and pour prioritizes convenience and speed for craft supply enthusiasts.

Pros and Cons of Cold Process Soap

Cold process soap offers full control over ingredients, allowing customization with natural oils, but requires a lengthy curing time of 4 to 6 weeks. This method produces a harder, longer-lasting bar with superior moisturizing qualities due to retained glycerin, yet it demands more skill and safety precautions because of lye handling. Cold process soap may also have a rustic appearance compared to the uniform look of melt and pour soap.

Pros and Cons of Melt and Pour Soap

Melt and pour soap offers the advantage of simplicity and speed, making it ideal for beginners and small-scale crafters who want to create custom soaps without handling lye. This pre-made base allows for extensive customization with colors, fragrances, and additives while reducing the risk of chemical hazards. However, melt and pour soap may lack the durability and traditional qualities of cold process soap, often resulting in a softer bar that can melt faster with frequent use.

Cold Process Soap vs Melt and Pour Soap Infographic

productdif.com

productdif.com