Hand spinning produces unique, textured yarns with variations in thickness and twist, offering artisans full control over the fiber quality and creativity. Machine spinning delivers consistent, uniform yarns with high efficiency, ideal for large-scale production and durability. Choosing between hand spinning and machine spinning depends on the desired aesthetic, production volume, and personal craftsmanship preferences.

Table of Comparison

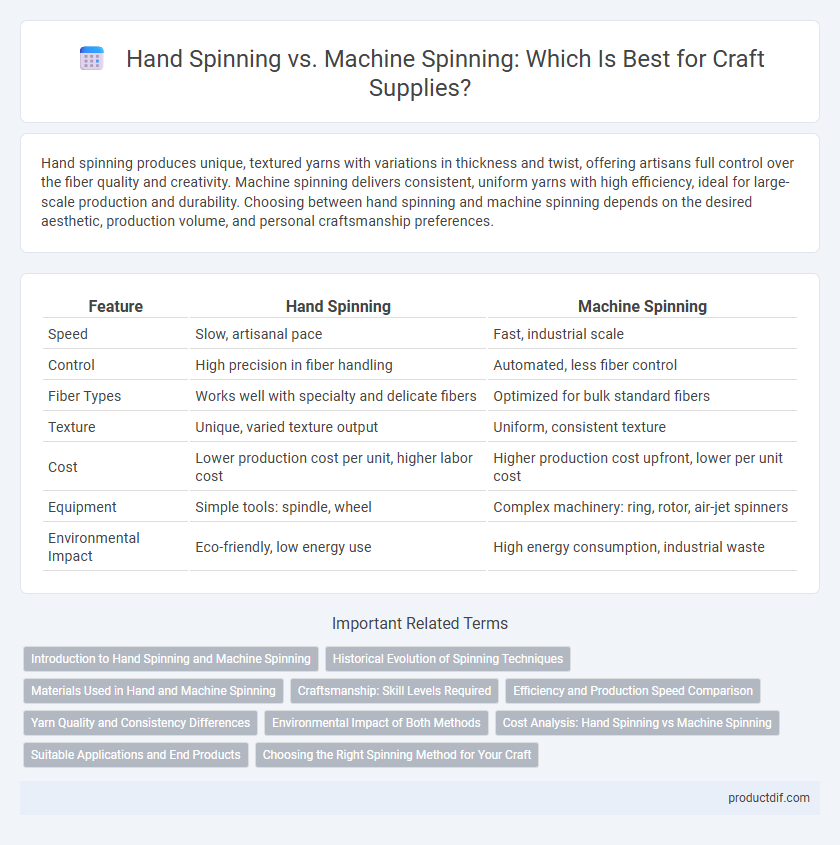

| Feature | Hand Spinning | Machine Spinning |

|---|---|---|

| Speed | Slow, artisanal pace | Fast, industrial scale |

| Control | High precision in fiber handling | Automated, less fiber control |

| Fiber Types | Works well with specialty and delicate fibers | Optimized for bulk standard fibers |

| Texture | Unique, varied texture output | Uniform, consistent texture |

| Cost | Lower production cost per unit, higher labor cost | Higher production cost upfront, lower per unit cost |

| Equipment | Simple tools: spindle, wheel | Complex machinery: ring, rotor, air-jet spinners |

| Environmental Impact | Eco-friendly, low energy use | High energy consumption, industrial waste |

Introduction to Hand Spinning and Machine Spinning

Hand spinning involves manually twisting fiber into yarn using tools like spindles or spinning wheels, emphasizing craftsmanship and control over texture and thickness. Machine spinning uses automated equipment to rapidly produce large quantities of consistent yarn with less variation in quality. Both methods serve different purposes in craft supply, with hand spinning favored for artisanal projects and machine spinning for mass production.

Historical Evolution of Spinning Techniques

Hand spinning, dating back to prehistoric times, involved manually drawing out fibers and twisting them into yarn using tools like spindles and distaffs, forming the foundation of textile production across ancient civilizations. The Industrial Revolution introduced machine spinning with inventions such as the spinning jenny and Arkwright's water frame, dramatically increasing yarn production speed and consistency. This technological shift transformed the craft supply industry by enabling mass production, reducing labor intensity, and standardizing thread quality for widespread textile manufacturing.

Materials Used in Hand and Machine Spinning

Hand spinning typically utilizes natural fibers such as wool, alpaca, cotton, and flax, offering artisans greater control over fiber selection and blending for unique textures. Machine spinning predominantly processes large quantities of uniform fibers like synthetic polyester, acrylic, and commercially prepared wool blends, prioritizing consistency and efficiency. The choice of materials in hand spinning emphasizes quality and individuality, while machine spinning focuses on scalability and standardized output.

Craftsmanship: Skill Levels Required

Hand spinning demands high craftsmanship, requiring skilled artisans to control fiber tension and twist consistency for quality yarn. Machine spinning automates these processes, reducing manual skill but needing technical knowledge to operate and maintain equipment effectively. Mastery in hand spinning enhances creativity and unique texture outcomes, while machine spinning prioritizes efficiency and uniformity.

Efficiency and Production Speed Comparison

Hand spinning produces yarn at a slower rate, typically yielding only a few grams per hour, making it ideal for artisanal, small-batch crafts emphasizing quality and uniqueness. Machine spinning, using automated spinning frames, can generate several kilograms per hour, dramatically increasing production speed and efficiency for industrial-scale textile manufacturing. The stark contrast in throughput highlights machine spinning's advantage in meeting high demand, while hand spinning remains valued for traditional techniques and customization.

Yarn Quality and Consistency Differences

Hand spinning produces yarn with unique texture and character, showcasing slight irregularities that enhance artisanal appeal. Machine spinning offers superior consistency, uniform thickness, and strength, ideal for commercial production requiring precise quality control. Yarn quality from machines ensures even tension and smooth finish, while hand-spun yarn highlights natural variations valued by crafters for its distinctive aesthetic.

Environmental Impact of Both Methods

Hand spinning uses natural fibers and minimal energy, significantly reducing carbon emissions and waste compared to machine spinning. Machine spinning consumes large amounts of electricity, often sourced from fossil fuels, and produces more industrial waste and pollution. Choosing hand spinning supports sustainable craft practices by lowering environmental impact and preserving traditional skills.

Cost Analysis: Hand Spinning vs Machine Spinning

Hand spinning incurs higher labor costs due to the time-intensive process of manually twisting fibers, making it less economical for large-scale production. Machine spinning lowers per-unit costs by automating fiber processing, increasing output speed and efficiency, while requiring significant initial capital investment in machinery. Cost analysis reveals hand spinning suits artisanal or small-batch projects, whereas machine spinning dominates industrial-scale operations for cost efficiency.

Suitable Applications and End Products

Hand spinning excels in producing unique, artisanal yarns ideal for custom knitting, weaving, and delicate textile arts where texture and individuality matter. Machine spinning suits large-scale production of consistent, uniform yarns used in mass-market garments, industrial fabrics, and commercial knitting projects. Each method aligns with different craft supply needs, where hand spinning delivers creativity and machine spinning ensures efficiency and volume.

Choosing the Right Spinning Method for Your Craft

Hand spinning offers unparalleled control over fiber texture and thickness, making it ideal for artisans seeking unique, customized yarns. Machine spinning provides faster production and consistent yarn quality, suited for large-scale projects or commercial use. Evaluating your project scale, desired yarn characteristics, and time availability helps determine whether hand spinning or machine spinning aligns best with your craft goals.

Hand Spinning vs Machine Spinning Infographic

productdif.com

productdif.com