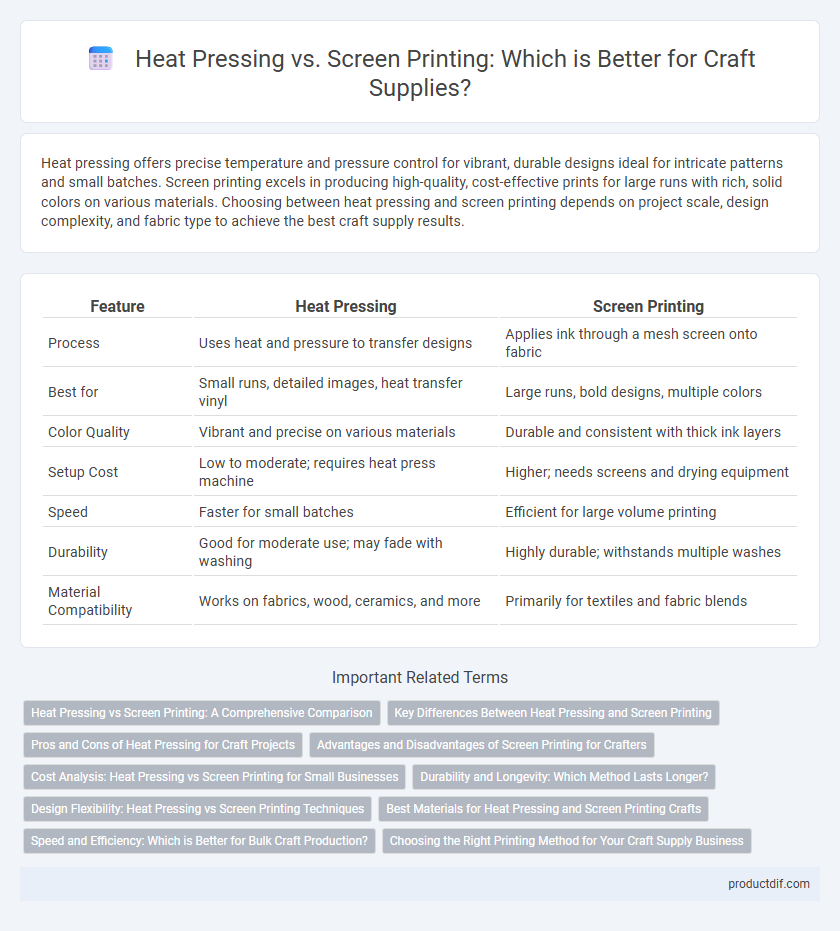

Heat pressing offers precise temperature and pressure control for vibrant, durable designs ideal for intricate patterns and small batches. Screen printing excels in producing high-quality, cost-effective prints for large runs with rich, solid colors on various materials. Choosing between heat pressing and screen printing depends on project scale, design complexity, and fabric type to achieve the best craft supply results.

Table of Comparison

| Feature | Heat Pressing | Screen Printing |

|---|---|---|

| Process | Uses heat and pressure to transfer designs | Applies ink through a mesh screen onto fabric |

| Best for | Small runs, detailed images, heat transfer vinyl | Large runs, bold designs, multiple colors |

| Color Quality | Vibrant and precise on various materials | Durable and consistent with thick ink layers |

| Setup Cost | Low to moderate; requires heat press machine | Higher; needs screens and drying equipment |

| Speed | Faster for small batches | Efficient for large volume printing |

| Durability | Good for moderate use; may fade with washing | Highly durable; withstands multiple washes |

| Material Compatibility | Works on fabrics, wood, ceramics, and more | Primarily for textiles and fabric blends |

Heat Pressing vs Screen Printing: A Comprehensive Comparison

Heat pressing offers precise control over temperature and pressure, making it ideal for detailed, multi-color designs on various fabric types, while screen printing excels in producing large volumes with vibrant, long-lasting ink layers. Heat pressing requires minimal setup and is cost-effective for small batches or custom items, whereas screen printing involves complex stencils and higher initial costs but benefits from efficiency in mass production. Both methods impact durability and texture differently: heat pressing embeds designs smoothly into the fabric without raised ink, in contrast to screen printing's textured, thicker ink application that withstands extensive washing.

Key Differences Between Heat Pressing and Screen Printing

Heat pressing uses heat and pressure to transfer vinyl or designs onto materials, providing precise and vibrant prints ideal for small runs and custom designs. Screen printing involves pushing ink through a mesh screen to create durable and cost-effective prints, especially suitable for large batches and multi-color designs. Heat pressing offers faster turnaround times with less setup, while screen printing excels in producing consistent, long-lasting prints with superior ink adhesion.

Pros and Cons of Heat Pressing for Craft Projects

Heat pressing offers precise temperature and pressure control, resulting in durable and vibrant designs ideal for fabric crafts and personalized items. Its quick setup and easy operation make it suitable for small to medium batches, though it may require investment in equipment and can be less efficient for large-scale production. Unlike screen printing, heat pressing provides greater versatility with diverse heat transfer materials but may produce less textured and layered effects.

Advantages and Disadvantages of Screen Printing for Crafters

Screen printing offers crafters vibrant, long-lasting designs with high ink opacity and durability, making it ideal for bulk production and intricate patterns on various materials. The process requires specialized equipment and can be time-consuming to set up, which may limit its cost-effectiveness and flexibility for small runs or quick design changes. Additionally, screen printing involves using stencils and screens, necessitating cleanup and storage space that crafters should consider for efficient workflow.

Cost Analysis: Heat Pressing vs Screen Printing for Small Businesses

Heat pressing offers lower upfront costs for small businesses, requiring a one-time purchase of a heat press machine and printable transfer materials. Screen printing involves higher initial expenses due to the need for screens, inks, and equipment, but becomes more cost-effective at higher volumes thanks to lower per-unit costs. For low to medium runs, heat pressing provides greater cost efficiency, while screen printing suits large-scale production with economy of scale benefits.

Durability and Longevity: Which Method Lasts Longer?

Heat pressing delivers exceptional durability by using heat and pressure to firmly bond vinyl or transfer materials to fabric, resulting in merchandise that withstands numerous washes without fading or cracking. Screen printing embeds ink directly into the fabric fibers, offering excellent longevity but may gradually lose vibrancy over extensive wear and time. For long-lasting, vibrant designs, heat pressing is often preferred in craft supply projects requiring frequent laundering.

Design Flexibility: Heat Pressing vs Screen Printing Techniques

Heat pressing offers superior design flexibility by enabling full-color, complex, and photorealistic images without the limitations of color separations required in screen printing. Screen printing excels in producing vibrant, durable designs but is best suited for simpler, fewer-color graphics due to stencil and ink layering constraints. For intricate, multi-color, or gradient designs, heat pressing provides greater versatility and customization options.

Best Materials for Heat Pressing and Screen Printing Crafts

Heat pressing works best with materials like cotton, polyester, and cotton-poly blends due to their ability to withstand high heat and pressure, resulting in durable and vibrant designs. Screen printing excels on natural fibers such as 100% cotton and linen, as well as on canvas and leather, providing excellent ink absorption and longevity. Choosing the right material enhances the quality and durability of both heat pressing and screen printing crafts.

Speed and Efficiency: Which is Better for Bulk Craft Production?

Heat pressing offers faster turnaround times with its simple setup and quick transfer process, making it ideal for bulk craft production where speed is crucial. Screen printing, while slower to set up, excels in efficiency for very large runs due to its ability to produce consistent high-quality prints at scale. For projects with tight deadlines and moderate quantities, heat pressing ensures rapid output, whereas screen printing is better suited for massive orders demanding cost-effective mass production.

Choosing the Right Printing Method for Your Craft Supply Business

Heat pressing offers precise detail and vibrant color transfer ideal for complex designs on fabrics, making it suitable for small to medium batch productions in a craft supply business. Screen printing excels in cost efficiency and durability for large volume runs, providing rich, long-lasting prints on various materials. Evaluating order size, design complexity, and substrate type ensures selecting the optimal printing method to maximize quality and profitability in your craft supply operations.

Heat Pressing vs Screen Printing Infographic

productdif.com

productdif.com