Hand-dyeing offers unique color variations and a personalized touch to craft supplies, creating one-of-a-kind pieces with rich textures and depth. Machine-dyeing ensures consistent, uniform color application that is efficient and ideal for large-scale production. Selecting between hand-dyeing and machine-dyeing depends on the desired aesthetic and project scale, balancing artisanal quality with production speed.

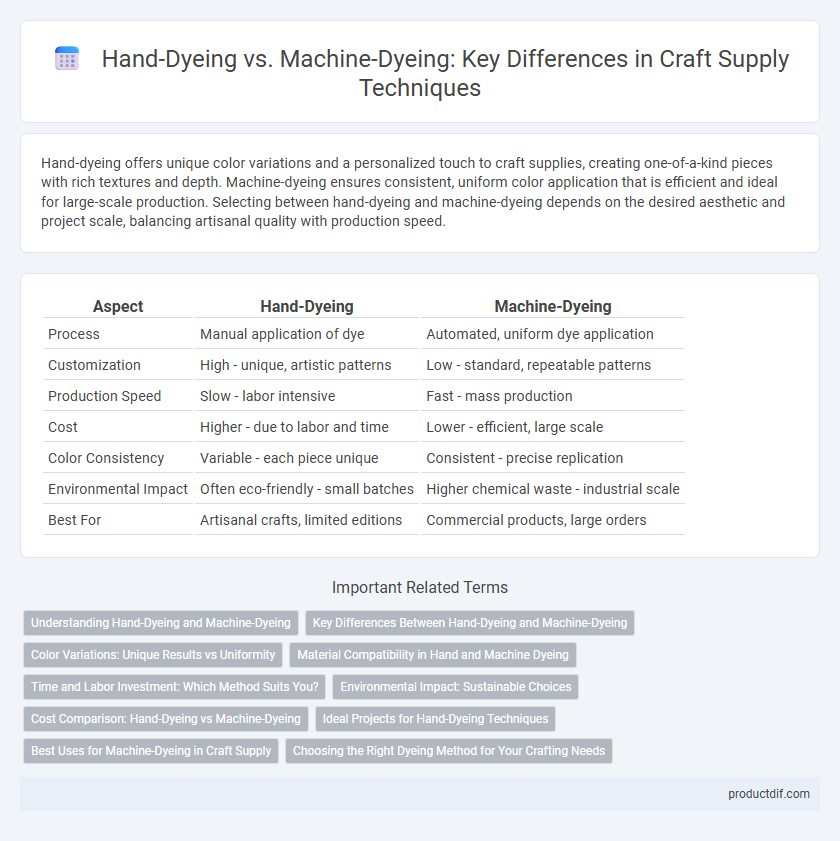

Table of Comparison

| Aspect | Hand-Dyeing | Machine-Dyeing |

|---|---|---|

| Process | Manual application of dye | Automated, uniform dye application |

| Customization | High - unique, artistic patterns | Low - standard, repeatable patterns |

| Production Speed | Slow - labor intensive | Fast - mass production |

| Cost | Higher - due to labor and time | Lower - efficient, large scale |

| Color Consistency | Variable - each piece unique | Consistent - precise replication |

| Environmental Impact | Often eco-friendly - small batches | Higher chemical waste - industrial scale |

| Best For | Artisanal crafts, limited editions | Commercial products, large orders |

Understanding Hand-Dyeing and Machine-Dyeing

Hand-dyeing involves manually applying dyes to fibers or fabrics, resulting in unique color variations and patterns that are highly valued in craft supply markets. Machine-dyeing uses industrial equipment to uniformly color large quantities of materials, offering consistent results and efficiency for mass production. Understanding these differences helps crafters choose between bespoke, artisanal textures and standardized, scalable options for their projects.

Key Differences Between Hand-Dyeing and Machine-Dyeing

Hand-dyeing involves manually applying color to fabrics or yarns, resulting in unique variations and richer color depth due to inconsistent absorption, whereas machine-dyeing uses automated processes for uniform color distribution and higher production efficiency. The hand-dyeing process is labor-intensive and ideal for small batches or artisanal projects, while machine-dyeing suits large-scale manufacturing with precise color matching and faster turnaround times. Hand-dyeing allows creative expression with customized patterns, whereas machine-dyeing emphasizes consistency and scalability in craft supply production.

Color Variations: Unique Results vs Uniformity

Hand-dyeing produces distinctive color variations and subtle gradients, giving each craft supply a unique appearance that enhances artisanal projects. Machine-dyeing ensures consistent, uniform colors across large batches, ideal for commercial production requiring precise color matching. Choosing between these methods depends on whether the priority is individualized character or reliable color consistency.

Material Compatibility in Hand and Machine Dyeing

Hand-dyeing offers greater versatility for natural fibers such as cotton, silk, and wool, allowing for rich, multidimensional color effects that machines often cannot replicate. Machine-dyeing excels with synthetic materials like polyester and nylon, providing uniform color application and faster processing times. Both methods require specific dye types and fabric treatments to ensure optimal color absorption and durability, making material compatibility a key factor in choosing the appropriate dyeing technique.

Time and Labor Investment: Which Method Suits You?

Hand-dyeing demands significant time and labor investment, as each piece is individually processed, allowing for unique color variations and artisanal quality. Machine-dyeing offers rapid, consistent results, ideal for bulk production with minimal manual effort. Choosing between these methods depends on your project scale, desired customization, and available resources.

Environmental Impact: Sustainable Choices

Hand-dyeing typically uses natural dyes and small batches, resulting in lower water consumption and reduced chemical pollution compared to machine-dyeing, which often relies on synthetic dyes and large-scale industrial processes that generate significant wastewater and chemical waste. Sustainable hand-dyeing minimizes environmental impact by promoting biodegradable materials and local sourcing, whereas machine-dyeing contributes to higher carbon footprints through energy-intensive operations. Choosing hand-dyeing processes supports eco-friendly craft supply practices by reducing pollution and conserving resources.

Cost Comparison: Hand-Dyeing vs Machine-Dyeing

Hand-dyeing typically incurs higher labor costs due to the time-intensive, artisanal process, making it more expensive per unit compared to machine-dyeing. Machine-dyeing benefits from automation and economies of scale, significantly reducing production time and lowering overall costs for large batches. Small businesses or boutique crafters may prefer hand-dyeing despite the higher cost for its unique, custom color results, while mass producers favor machine-dyeing for efficiency and cost-effectiveness.

Ideal Projects for Hand-Dyeing Techniques

Hand-dyeing techniques are ideal for small-batch craft projects, including artisanal yarns, custom fabric panels, and unique textile accessories where color variation and personalization are desired. These projects benefit from the nuanced, organic color blends achievable only through manual dye application, making each piece distinct and vibrant. Hand-dyeing excels in creating gradient effects, tie-dye patterns, and multi-colored designs that machine-dyeing processes cannot replicate with the same level of artistic control.

Best Uses for Machine-Dyeing in Craft Supply

Machine-dyeing offers consistent color application, making it ideal for large-scale craft supply production and projects requiring uniformity across multiple items. Its efficiency and speed suit industries producing yarn, fabric, or paper in bulk, where precise color matching is crucial. Machine-dyeing also supports complex color patterns and gradients that are difficult to achieve manually, enhancing product variety and quality in commercial craft supplies.

Choosing the Right Dyeing Method for Your Crafting Needs

Hand-dyeing offers unique color variations and personalized control, ideal for small batches and custom projects in craft supply. Machine-dyeing ensures color consistency, efficiency, and scalability, making it suitable for larger orders and uniform results. Evaluating factors such as project size, desired finish, and budget helps determine the best dyeing method for your crafting needs.

Hand-dyeing vs Machine-dyeing Infographic

productdif.com

productdif.com