Felting needles have barbs that catch and tangle wool fibers to create three-dimensional shapes, making them essential for needle felting projects. Embroidery needles are smooth with a sharp point and an eye suitable for threading embroidery floss, designed for stitching on fabric without damaging the material. Choosing the correct needle depends on the craft: felting requires repeated stabbing motions to bind fibers, while embroidery involves precise, smooth stitches on cloth.

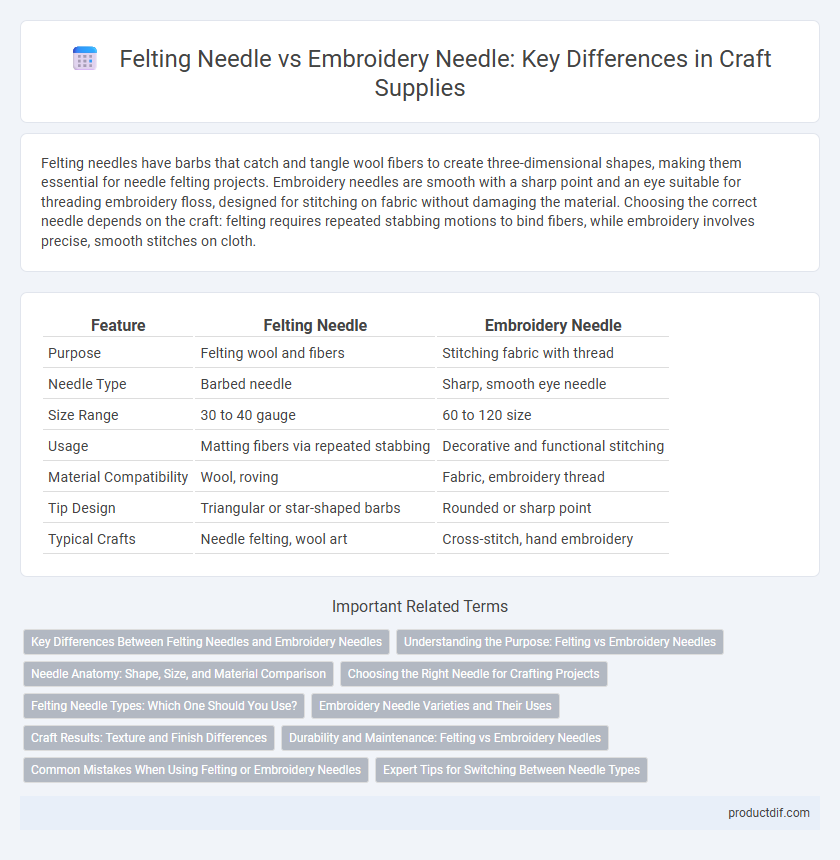

Table of Comparison

| Feature | Felting Needle | Embroidery Needle |

|---|---|---|

| Purpose | Felting wool and fibers | Stitching fabric with thread |

| Needle Type | Barbed needle | Sharp, smooth eye needle |

| Size Range | 30 to 40 gauge | 60 to 120 size |

| Usage | Matting fibers via repeated stabbing | Decorative and functional stitching |

| Material Compatibility | Wool, roving | Fabric, embroidery thread |

| Tip Design | Triangular or star-shaped barbs | Rounded or sharp point |

| Typical Crafts | Needle felting, wool art | Cross-stitch, hand embroidery |

Key Differences Between Felting Needles and Embroidery Needles

Felting needles feature barbs along the shaft designed to interlock wool fibers during the felting process, whereas embroidery needles have smooth shafts to allow easy stitching of fabric without damaging threads. Felting needles are typically thicker and more rigid, enabling them to penetrate dense wool layers, while embroidery needles are finer and more flexible, optimized for precise thread placement on textiles. The distinctive tip shapes also differ: felting needles often have a triangular or chisel-shaped point for felting efficiency, contrasted with the rounded tips of embroidery needles that prevent fabric damage.

Understanding the Purpose: Felting vs Embroidery Needles

Felting needles have barbs designed to interlock wool fibers for creating dense, sculpted shapes, while embroidery needles have smooth shafts for threading and stitching fabric with precision. The purpose of felting needles is to bind loose fibers together during the felting process, contrasting with embroidery needles which focus on guiding embroidery threads through cloth without damaging the fabric. Selecting the appropriate needle enhances craft quality by matching tool function to material manipulation techniques.

Needle Anatomy: Shape, Size, and Material Comparison

Felting needles feature a uniquely barbed shaft designed to interlock wool fibers, typically made of hardened steel and varying in size from thin for fine details to thick for dense felting. Embroidery needles have a smooth, slender body with a sharp point and an elongated eye to accommodate embroidery floss, commonly crafted from nickel-plated steel for durability and smooth fabric penetration. The contrasting needle anatomy reflects their specialized uses: felting needles prioritize fiber entanglement with barbs, while embroidery needles emphasize thread precision and fabric compatibility.

Choosing the Right Needle for Crafting Projects

Felting needles, featuring barbs along their shafts, are specifically designed for compressing wool fibers in needle felting projects, creating dense, sculpted shapes with ease. Embroidery needles, with smooth shafts and sharp points, excel at threading various types of embroidery floss through fabric without damaging the material. Selecting the right needle depends on the craft focus: choose felting needles for sculpting fibers and embroidery needles for detailed fabric stitching to ensure precision and durability in your projects.

Felting Needle Types: Which One Should You Use?

Felting needles come in various types, including triangle, star, and spiral barbs, each designed to catch and mesh wool fibers differently for needle felting projects. Triangle needles are best for general felting and shaping, star needles provide better control with more barbs for faster felting, while spiral barbs excel at creating smooth surfaces and intricate details. Choosing the right felting needle depends on your project's requirements for texture, fiber density, and detailing compared to embroidery needles, which are smooth and used primarily for stitching rather than felting.

Embroidery Needle Varieties and Their Uses

Embroidery needles come in various types, including crewel, tapestry, and milliners, each designed for specific fabric and thread combinations. Crewel needles feature sharp points and medium-long eyes, perfect for wool embroidery, while tapestry needles have blunt tips suited for counted cross-stitch on even-weave fabrics. Milliners needles, also known as straw needles, possess long, slender shafts ideal for intricate ribbon embroidery and beading work.

Craft Results: Texture and Finish Differences

Felting needles create dense, sculpted textures by matting wool fibers through repeated poking, resulting in a firm, three-dimensional finish ideal for sculptural crafts. Embroidery needles, designed for threading fabric, produce smooth, flat surfaces with precise stitch definition, enhancing detailed patterns and clean lines in textile art. Craft projects benefit from choosing felting needles for textured, tactile effects, while embroidery needles excel in refined, polished finishes.

Durability and Maintenance: Felting vs Embroidery Needles

Felting needles are crafted from hardened steel, ensuring high durability to withstand repeated poking through dense wool fibers, while embroidery needles are typically made from softer metals that can bend or dull more quickly under heavy use. Maintenance of felting needles involves regular replacement rather than sharpening, as their barbs lose effectiveness over time, whereas embroidery needles require careful cleaning and occasional replacement depending on fabric type and frequency of use. Both needle types demand proper storage to prevent damage, but felting needles' specialized design prioritizes long-lasting performance in dense textile crafting.

Common Mistakes When Using Felting or Embroidery Needles

Using a felting needle for embroidery can cause fabric damage due to its coarse barbs designed for matting wool fibers, while an embroidery needle lacks the rigidity and sharpness needed for effective felting. Common mistakes include applying excessive pressure with felting needles, leading to broken needles or distorted projects, and using embroidery needles for wool felting, resulting in poor fiber binding. Correct needle selection and understanding the structural differences between felting and embroidery needles are crucial for achieving clean, professional craft results.

Expert Tips for Switching Between Needle Types

When switching between felting needles and embroidery needles, experts recommend choosing the needle based on fabric type and project goals to ensure optimal results. Felting needles have barbs designed to interlock wool fibers, making them ideal for dense, textured projects, while embroidery needles have smooth shafts and sharp points suited for detailed stitching on woven fabrics. Maintaining separate storages and regularly inspecting needle integrity enhances precision and prevents damage during needle changes in craft supplies.

Felting needle vs Embroidery needle Infographic

productdif.com

productdif.com