Loom weaving offers precision and speed, making it ideal for creating large, consistent fabric pieces with intricate patterns. Needle weaving provides flexibility and detailed control, allowing for intricate designs and fine textures in smaller projects. Choosing between loom and needle weaving depends on the scale and complexity of the craft project.

Table of Comparison

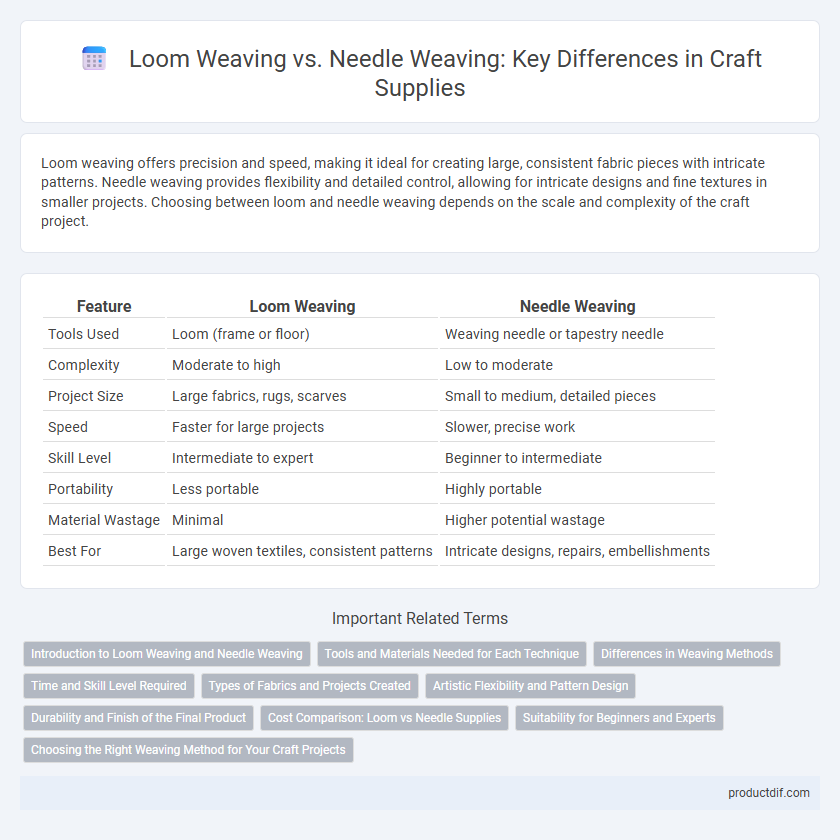

| Feature | Loom Weaving | Needle Weaving |

|---|---|---|

| Tools Used | Loom (frame or floor) | Weaving needle or tapestry needle |

| Complexity | Moderate to high | Low to moderate |

| Project Size | Large fabrics, rugs, scarves | Small to medium, detailed pieces |

| Speed | Faster for large projects | Slower, precise work |

| Skill Level | Intermediate to expert | Beginner to intermediate |

| Portability | Less portable | Highly portable |

| Material Wastage | Minimal | Higher potential wastage |

| Best For | Large woven textiles, consistent patterns | Intricate designs, repairs, embellishments |

Introduction to Loom Weaving and Needle Weaving

Loom weaving utilizes a rigid frame to interlace warp and weft threads, enabling the creation of consistent, intricate patterns ideal for larger textile projects. Needle weaving involves manually stitching threads with a needle, offering greater precision for detailed designs and smaller craft items. Both techniques serve distinct purposes in craft supply, balancing efficiency and artistic control.

Tools and Materials Needed for Each Technique

Loom weaving requires a loom, warp threads, weft threads, and a shuttle or bobbin to interlace fibers efficiently for large-scale fabric creation. Needle weaving utilizes a weaving needle and yarn or thread, allowing greater precision and flexibility for smaller or detailed projects without the need for a loom. Both techniques depend heavily on the choice of fibers such as wool, cotton, or synthetic threads, impacting the texture and durability of the finished product.

Differences in Weaving Methods

Loom weaving uses a structured frame to interlace warp and weft threads in a grid pattern, allowing for faster production and consistent tension, whereas needle weaving involves manually pulling threads through fabric using a needle, resulting in more intricate and precise designs. Loom weaving is ideal for creating larger textiles with uniform patterns, while needle weaving offers greater flexibility for detailed embellishments and complex textures. The fundamental difference lies in the mechanized process of loom weaving versus the hand-crafted technique of needle weaving, impacting speed, scale, and design complexity.

Time and Skill Level Required

Loom weaving typically requires less time for larger projects due to its automated structure, making it efficient for consistent patterns. Needle weaving demands higher skill and patience, as it involves precise hand movements and detailed control over individual threads. Beginners often find loom weaving more accessible, while needle weaving suits experienced crafters seeking intricate designs.

Types of Fabrics and Projects Created

Loom weaving produces tightly woven fabrics such as cotton, wool, and silk, ideal for large-scale projects like scarves, blankets, and tapestries due to its uniform texture and strength. Needle weaving, often used for smaller, detailed works like embroidery and decorative patches, allows for intricate patterns on various fabric types including linen and canvas. Both techniques influence the texture and durability of the final craft, with loom weaving suited for sturdy, wearable textiles and needle weaving favored for artistic embellishments.

Artistic Flexibility and Pattern Design

Loom weaving offers greater artistic flexibility by allowing complex and repeatable patterns through precise tension control and multiple warp threads, ideal for intricate textile designs. Needle weaving provides more freedom for freeform, detailed motifs and texture variations, perfect for unique, one-of-a-kind artistic creations. Choosing between loom and needle weaving depends on whether the project prioritizes structured pattern accuracy or individualized artistic expression.

Durability and Finish of the Final Product

Loom weaving produces highly durable fabrics with consistent tension, resulting in a strong and even finish ideal for heavy-use items like rugs and upholstery. Needle weaving offers greater flexibility and detail control, allowing intricate patterns but often yields a softer, less uniform finish that may wear faster under stress. Choosing between the two techniques depends on the desired balance between durability and decorative precision in the final craft product.

Cost Comparison: Loom vs Needle Supplies

Loom weaving requires an initial investment in a loom that ranges from $50 to over $500 depending on size and complexity, while needle weaving primarily involves purchasing needles priced between $2 and $10 each. Warp threads, heddles, and shuttles add to loom weaving costs, whereas needle weaving typically relies on yarns and various needle types, often making it more budget-friendly for beginners. Analyzing long-term expenditure, loom weaving supplies lead to higher upfront costs but offer efficiency for large projects, whereas needle weaving remains economical with minimal supplies ideal for smaller, detailed crafts.

Suitability for Beginners and Experts

Loom weaving offers structured patterns and consistent tension, making it highly suitable for beginners seeking guided techniques and uniform results. Needle weaving requires fine motor skills and creative freedom, appealing more to experts who enjoy intricate detail work and customization. Both methods enhance textile crafting skills, but loom weaving provides a more accessible entry point for novices compared to the manual dexterity demanded by needle weaving.

Choosing the Right Weaving Method for Your Craft Projects

Loom weaving offers speed and consistency, making it ideal for large textile projects and intricate patterns, while needle weaving provides detailed control perfect for smaller, delicate crafts or repairs. Selecting between loom and needle weaving depends on project size, thread type, and desired pattern complexity, ensuring the chosen method aligns with your creative goals. Understanding these differences enhances fabric quality and optimizes crafting efficiency.

Loom weaving vs Needle weaving Infographic

productdif.com

productdif.com