Microfiltration and ultrafiltration are advanced membrane filtration techniques widely used in beverage processing to enhance product quality and safety. Microfiltration removes larger particles such as yeast and bacteria, improving clarity without affecting flavor, while ultrafiltration targets smaller molecules like proteins and fats, enabling better sterilization and component separation. Choosing between microfiltration and ultrafiltration depends on the desired level of filtration precision, with microfiltration favored for clarification and ultrafiltration for more refined purification and concentration tasks.

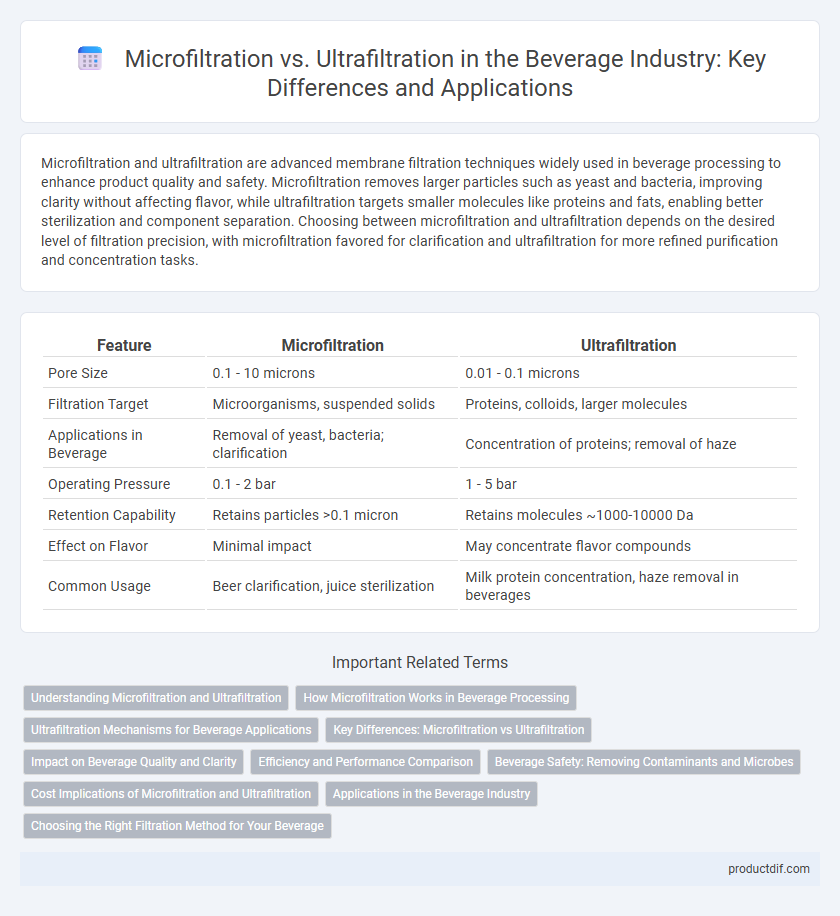

Table of Comparison

| Feature | Microfiltration | Ultrafiltration |

|---|---|---|

| Pore Size | 0.1 - 10 microns | 0.01 - 0.1 microns |

| Filtration Target | Microorganisms, suspended solids | Proteins, colloids, larger molecules |

| Applications in Beverage | Removal of yeast, bacteria; clarification | Concentration of proteins; removal of haze |

| Operating Pressure | 0.1 - 2 bar | 1 - 5 bar |

| Retention Capability | Retains particles >0.1 micron | Retains molecules ~1000-10000 Da |

| Effect on Flavor | Minimal impact | May concentrate flavor compounds |

| Common Usage | Beer clarification, juice sterilization | Milk protein concentration, haze removal in beverages |

Understanding Microfiltration and Ultrafiltration

Microfiltration and ultrafiltration are membrane filtration techniques used to clarify and purify beverages by removing suspended solids, bacteria, and other impurities. Microfiltration operates with larger pore sizes, typically ranging from 0.1 to 10 microns, effectively removing yeast and bacteria while preserving flavor components. Ultrafiltration uses smaller pores, around 0.01 to 0.1 microns, to eliminate proteins and viruses, enhancing beverage stability and extending shelf life without the need for heat treatment.

How Microfiltration Works in Beverage Processing

Microfiltration in beverage processing employs porous membranes with pore sizes typically between 0.1 and 10 microns to remove suspended solids, yeast, and bacteria without affecting the beverage's flavor or aroma. This low-pressure filtration technique ensures clarity and stability by physically separating microorganisms and particulates while preserving essential nutrients and sensory properties. Microfiltration is widely used in wine, beer, and juice production to extend shelf life and maintain product quality.

Ultrafiltration Mechanisms for Beverage Applications

Ultrafiltration in beverage applications utilizes semi-permeable membranes with pore sizes ranging from 0.01 to 0.1 microns to separate macromolecules such as proteins and polysaccharides from liquids, enhancing clarity and stability. This process effectively removes suspended solids, microbes, and colloidal particles while maintaining essential flavor compounds and nutrients, making it ideal for juices, dairy, and wine production. Membrane materials commonly used include polysulfone and polyethersulfone, selected for their chemical resistance and durability under varying pH and temperature conditions.

Key Differences: Microfiltration vs Ultrafiltration

Microfiltration and ultrafiltration are critical membrane filtration processes used in beverage production to ensure product clarity and safety. Microfiltration uses membrane pores sized between 0.1 to 10 microns, effectively removing suspended solids, bacteria, and yeast, while ultrafiltration has smaller pore sizes around 0.01 to 0.1 microns, targeting proteins, viruses, and larger molecules for purification. These filtration techniques differ primarily in pore size, filtration pressure, and the types of contaminants they remove, influencing beer, wine, and juice stabilization processes.

Impact on Beverage Quality and Clarity

Microfiltration uses larger pore sizes (0.1-10 microns) to effectively remove yeast and bacteria, preserving delicate flavors and aroma compounds in beverages while enhancing clarity. Ultrafiltration employs smaller pores (0.01-0.1 microns) that can remove proteins and polyphenols, potentially leading to a cleaner taste but sometimes altering mouthfeel and reducing flavor complexity. Beverage producers must balance microfiltration's ability to maintain sensory qualities with ultrafiltration's superior removal of haze-causing agents to achieve optimal quality and clarity.

Efficiency and Performance Comparison

Microfiltration and ultrafiltration differ significantly in pore size and filtration precision, with microfiltration removing particles between 0.1 to 10 microns and ultrafiltration targeting molecules as small as 0.01 microns. Ultrafiltration offers superior efficiency in retaining proteins, bacteria, and colloids, enhancing beverage clarity and stability, while microfiltration excels in removing yeasts and molds with lower operational costs. Performance in beverage processing hinges on ultrafiltration's higher retention capabilities, contrasted with microfiltration's faster throughput and energy efficiency, making ultrafiltration ideal for high-purity applications and microfiltration suited for preliminary clarification.

Beverage Safety: Removing Contaminants and Microbes

Microfiltration effectively removes larger particles, yeast, and bacteria, enhancing beverage safety by reducing microbial contamination without affecting flavor. Ultrafiltration targets smaller molecules including proteins and viruses, providing a deeper level of purification critical for maintaining product stability and shelf life. Both technologies improve beverage quality, with microfiltration suited for basic microbial control and ultrafiltration for advanced contaminant removal.

Cost Implications of Microfiltration and Ultrafiltration

Microfiltration typically involves lower operational and maintenance costs compared to ultrafiltration due to its larger pore size and less frequent membrane replacement. Ultrafiltration membranes demand higher energy consumption and more rigorous cleaning protocols, increasing the overall cost, especially in beverage applications requiring fine filtration and microbial stability. Investing in ultrafiltration systems can lead to higher initial capital expenditure but offers enhanced product clarity and shelf-life, justifying the expense for premium beverage production.

Applications in the Beverage Industry

Microfiltration and ultrafiltration are critical membrane technologies in the beverage industry, used for clarifying and stabilizing products like beer, wine, and fruit juices. Microfiltration efficiently removes suspended solids and bacteria, ensuring microbial stability without altering taste or aroma. Ultrafiltration offers finer filtration, targeting proteins and colloids to enhance shelf life and improve mouthfeel in dairy-based beverages and fruit concentrates.

Choosing the Right Filtration Method for Your Beverage

Microfiltration offers efficient removal of suspended solids and microorganisms, preserving flavor and aroma in beverages like beer and juice. Ultrafiltration excels in retaining proteins and large molecules, ideal for dairy and nutrient-rich drinks requiring clarity and stability. Selecting the right filtration method depends on beverage composition, desired shelf life, and quality goals to ensure optimal filtration performance and product integrity.

Microfiltration vs Ultrafiltration Infographic

productdif.com

productdif.com