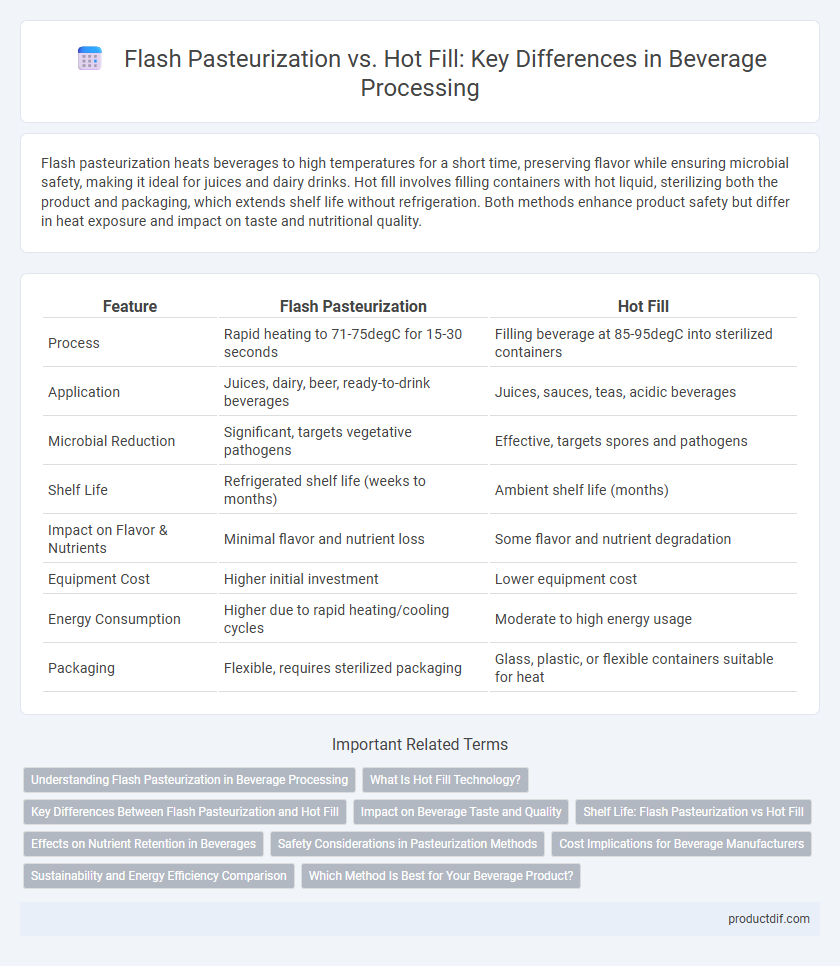

Flash pasteurization heats beverages to high temperatures for a short time, preserving flavor while ensuring microbial safety, making it ideal for juices and dairy drinks. Hot fill involves filling containers with hot liquid, sterilizing both the product and packaging, which extends shelf life without refrigeration. Both methods enhance product safety but differ in heat exposure and impact on taste and nutritional quality.

Table of Comparison

| Feature | Flash Pasteurization | Hot Fill |

|---|---|---|

| Process | Rapid heating to 71-75degC for 15-30 seconds | Filling beverage at 85-95degC into sterilized containers |

| Application | Juices, dairy, beer, ready-to-drink beverages | Juices, sauces, teas, acidic beverages |

| Microbial Reduction | Significant, targets vegetative pathogens | Effective, targets spores and pathogens |

| Shelf Life | Refrigerated shelf life (weeks to months) | Ambient shelf life (months) |

| Impact on Flavor & Nutrients | Minimal flavor and nutrient loss | Some flavor and nutrient degradation |

| Equipment Cost | Higher initial investment | Lower equipment cost |

| Energy Consumption | Higher due to rapid heating/cooling cycles | Moderate to high energy usage |

| Packaging | Flexible, requires sterilized packaging | Glass, plastic, or flexible containers suitable for heat |

Understanding Flash Pasteurization in Beverage Processing

Flash pasteurization rapidly heats beverages to 71.7degC (161degF) for 15 seconds, effectively reducing microbial load while preserving flavor and nutritional quality. This method contrasts with hot fill processing, which involves heating the beverage to near boiling temperatures before filling containers, often impacting taste and fresh attributes. Flash pasteurization offers a balance between safety and sensory preservation, making it ideal for juices, dairy, and ready-to-drink beverages.

What Is Hot Fill Technology?

Hot fill technology involves heating beverages to approximately 85-95degC before filling them into sterilized containers to ensure microbial safety and extend shelf life without preservatives. This method is commonly used for acidic drinks such as fruit juices, teas, and sports beverages, where high temperature effectively inactivates spoilage organisms. Hot fill processes balance product quality and safety by minimizing thermal degradation while maintaining flavor and nutritional value.

Key Differences Between Flash Pasteurization and Hot Fill

Flash pasteurization rapidly heats beverages to approximately 71-75degC for 15-30 seconds before immediate cooling to preserve flavor and nutrients, commonly used for juices and dairy products. Hot fill involves heating the beverage to 85-95degC and filling it into sterile containers while hot, effectively sterilizing both product and container for shelf stability without refrigeration. Flash pasteurization offers shorter processing times and better taste retention, whereas hot fill provides extended shelf life and strong microbial control but may alter flavor profiles.

Impact on Beverage Taste and Quality

Flash pasteurization preserves beverage taste and quality by rapidly heating to 71-75degC for 15-30 seconds, minimizing flavor degradation and nutrient loss. Hot fill involves filling the beverage at 85-95degC, which can cause subtle changes in flavor profiles and potential loss of volatile aroma compounds. Beverages subjected to flash pasteurization typically exhibit fresher taste profiles and better retention of sensory qualities compared to hot fill methods.

Shelf Life: Flash Pasteurization vs Hot Fill

Flash Pasteurization extends beverage shelf life by rapidly heating the product to high temperatures for a short time, effectively reducing microbial load while preserving flavor and nutritional quality. Hot Fill processes involve filling products at high temperatures, which can result in a longer shelf life by sterilizing both the beverage and container but may impact taste and nutrient retention more significantly. Both methods enhance shelf stability, with flash pasteurization offering a better balance between preservation and sensory quality compared to hot fill.

Effects on Nutrient Retention in Beverages

Flash pasteurization preserves more vitamins and antioxidants in beverages by applying high heat for a very short time, minimizing nutrient degradation. Hot fill processes involve prolonged exposure to high temperatures, often resulting in greater loss of heat-sensitive nutrients like vitamin C and certain B vitamins. The choice between these methods directly impacts the nutritional value and freshness perception in juice, dairy, and functional drink products.

Safety Considerations in Pasteurization Methods

Flash pasteurization employs rapid heating to 71.7degC (161degF) for 15 seconds, effectively eliminating pathogenic microorganisms while preserving beverage quality and extending shelf life. Hot fill pasteurization heats beverages to approximately 85-95degC (185-203degF) before filling, creating a sterile environment to prevent contamination but may impact flavor and nutrient retention. Both methods prioritize consumer safety by reducing microbial load, but flash pasteurization offers a balance between microbial control and sensory quality preservation.

Cost Implications for Beverage Manufacturers

Flash pasteurization generally involves higher upfront equipment costs but offers energy savings and reduced production time, making it cost-effective for large-scale beverage manufacturers. Hot fill requires less complex machinery but incurs higher energy costs due to prolonged heating and cooling cycles, impacting overall operational expenses. Choosing between the two methods depends on production volume, beverage type, and long-term cost efficiency goals.

Sustainability and Energy Efficiency Comparison

Flash pasteurization consumes significantly less energy than hot fill by rapidly heating beverages to high temperatures for short periods, reducing overall thermal exposure and energy use. Hot fill requires prolonged heating and maintaining elevated temperatures, leading to higher energy consumption and greater carbon emissions. Sustainable beverage production increasingly favors flash pasteurization due to its efficient energy use and lower environmental impact.

Which Method Is Best for Your Beverage Product?

Flash pasteurization offers rapid heat treatment that preserves flavor and nutrients, making it ideal for delicate beverages like juices and teas. Hot fill processes involve filling the product at high temperatures, ensuring effective microbial control and extended shelf life, suitable for acidic drinks such as fruit juices and sports beverages. Choosing the best method depends on product sensitivity, desired shelf life, and flavor retention priorities.

Flash Pasteurization vs Hot Fill Infographic

productdif.com

productdif.com