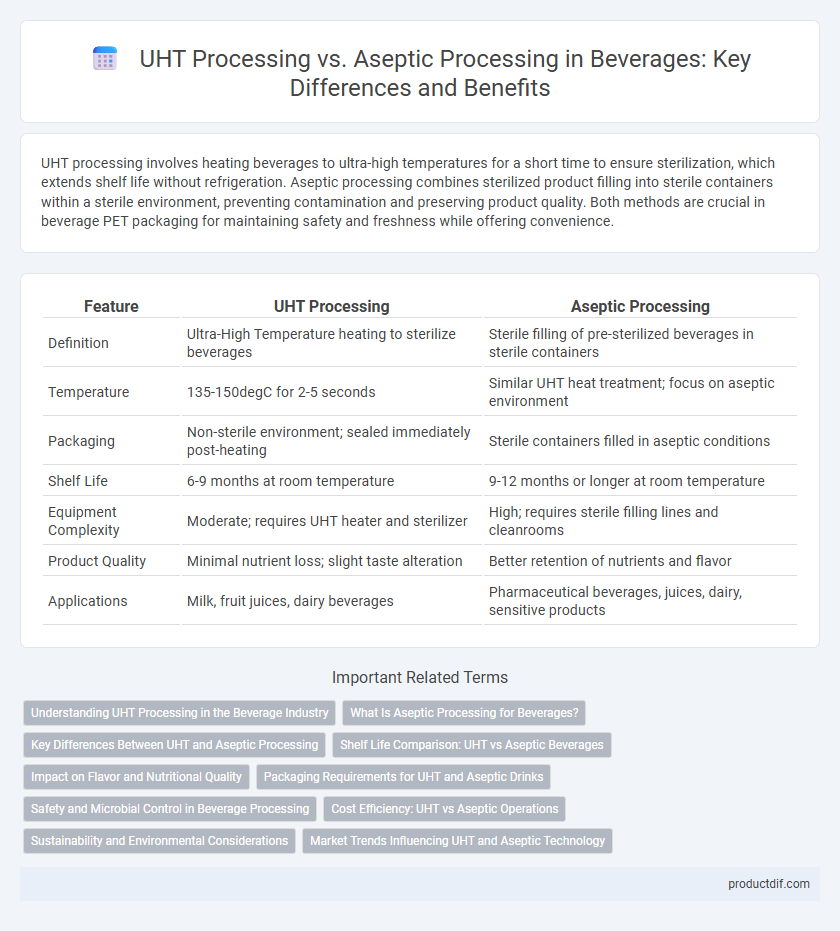

UHT processing involves heating beverages to ultra-high temperatures for a short time to ensure sterilization, which extends shelf life without refrigeration. Aseptic processing combines sterilized product filling into sterile containers within a sterile environment, preventing contamination and preserving product quality. Both methods are crucial in beverage PET packaging for maintaining safety and freshness while offering convenience.

Table of Comparison

| Feature | UHT Processing | Aseptic Processing |

|---|---|---|

| Definition | Ultra-High Temperature heating to sterilize beverages | Sterile filling of pre-sterilized beverages in sterile containers |

| Temperature | 135-150degC for 2-5 seconds | Similar UHT heat treatment; focus on aseptic environment |

| Packaging | Non-sterile environment; sealed immediately post-heating | Sterile containers filled in aseptic conditions |

| Shelf Life | 6-9 months at room temperature | 9-12 months or longer at room temperature |

| Equipment Complexity | Moderate; requires UHT heater and sterilizer | High; requires sterile filling lines and cleanrooms |

| Product Quality | Minimal nutrient loss; slight taste alteration | Better retention of nutrients and flavor |

| Applications | Milk, fruit juices, dairy beverages | Pharmaceutical beverages, juices, dairy, sensitive products |

Understanding UHT Processing in the Beverage Industry

UHT processing involves heating beverages to temperatures between 135-150degC for a few seconds to eliminate microbial contamination while preserving nutritional and sensory qualities. This method extends shelf life significantly without the need for refrigeration, making it ideal for milk, juices, and plant-based drinks. UHT processing contrasts with aseptic processing by treating products in a sterile environment post-heating, ensuring longer stability and reduced spoilage risk in ambient conditions.

What Is Aseptic Processing for Beverages?

Aseptic processing for beverages involves sterilizing the product and packaging separately before filling in a sterile environment to ensure extended shelf life without refrigeration. This method preserves the beverage's flavor, nutrients, and quality by preventing microbial contamination during packaging. UHT processing, often linked with aseptic techniques, rapidly heats the beverage to kill pathogens, making aseptic processing ideal for dairy, juice, and plant-based drinks requiring long-term storage.

Key Differences Between UHT and Aseptic Processing

UHT processing heats beverages to temperatures above 135degC for a few seconds to achieve sterilization, while aseptic processing involves sterilizing both the beverage and packaging separately before filling in a sterile environment. UHT is a single-step thermal treatment, whereas aseptic processing integrates sterilization with sterile filling, ensuring extended shelf life without refrigeration. The key difference lies in packaging sterilization and aseptic filling that significantly reduces contamination risks in aseptic processing compared to traditional UHT.

Shelf Life Comparison: UHT vs Aseptic Beverages

UHT processing extends shelf life by heating beverages to around 135-150degC for a few seconds, effectively killing microorganisms but slightly altering taste and nutritional content. Aseptic processing combines sterilized product filling in a sterile environment, allowing shelf life up to 6-12 months without refrigeration while preserving fresher taste and nutrients. Both methods enable long-term storage, yet aseptic processing generally offers superior shelf life stability and quality retention in beverages.

Impact on Flavor and Nutritional Quality

UHT processing subjects beverages to ultra-high temperatures for a few seconds, which can cause slight flavor changes and minor nutrient loss, particularly of heat-sensitive vitamins like vitamin C. Aseptic processing combines sterilized product and packaging in a sterile environment, preserving the original flavor profile and nutritional content more effectively than UHT. Studies show aseptic processing better maintains antioxidants and volatile compounds essential for beverage quality.

Packaging Requirements for UHT and Aseptic Drinks

UHT processing demands packaging that can withstand high temperatures during sterilization, typically using multilayer cartons or specially treated plastic bottles to maintain product safety and shelf life. Aseptic processing requires sterile packaging materials and hermetic sealing in a clean environment to prevent contamination, often employing laminated cartons or PET bottles with aseptic filling equipment. Both packaging methods prioritize barrier properties against oxygen and light to preserve the beverage's quality and extend its storage duration without refrigeration.

Safety and Microbial Control in Beverage Processing

UHT processing involves heating beverages to temperatures above 135degC for a few seconds, effectively eliminating spores and pathogenic microorganisms to ensure safety. Aseptic processing combines UHT sterilization with sterile packaging, maintaining the product's microbial stability without refrigeration. This method provides superior microbial control by preventing post-sterilization contamination, extending shelf life while preserving beverage quality.

Cost Efficiency: UHT vs Aseptic Operations

UHT processing typically offers lower upfront capital investment and faster production cycles, making it cost-efficient for high-volume beverage manufacturing. Aseptic processing, while involving higher initial equipment and facility costs, provides longer shelf life and reduced need for preservatives, which can lead to savings in distribution and storage over time. Companies must weigh these factors against production scale and product type to optimize overall cost efficiency in beverage operations.

Sustainability and Environmental Considerations

UHT processing uses high temperatures to sterilize beverages inside sealed containers, which may consume more energy but reduces the need for preservatives and refrigeration, contributing to longer shelf life and less food waste. Aseptic processing sterilizes both the product and packaging separately before filling, allowing for lightweight, recyclable packaging options that lower carbon footprint and transportation emissions. Both methods minimize spoilage and extend shelf life, but aseptic processing often offers greater sustainability benefits through reduced material usage and enhanced packaging recyclability.

Market Trends Influencing UHT and Aseptic Technology

UHT processing maintains a strong presence in dairy and juice sectors due to its cost-effectiveness and extended shelf life, especially in emerging markets with limited cold chain infrastructure. Aseptic processing gains traction in global beverage markets driven by consumer demand for preservative-free, fresh-tasting products and the expansion of ready-to-drink categories. Advancements in packaging materials and sustainability concerns further accelerate the adoption of aseptic technology in premium beverage segments worldwide.

UHT Processing vs Aseptic Processing Infographic

productdif.com

productdif.com