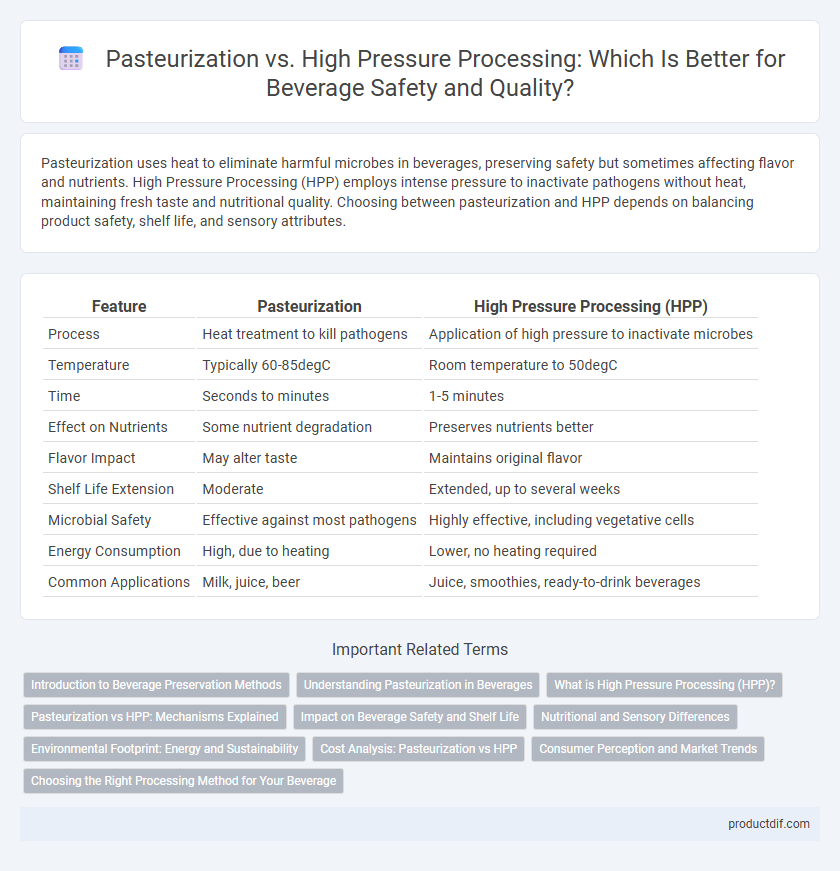

Pasteurization uses heat to eliminate harmful microbes in beverages, preserving safety but sometimes affecting flavor and nutrients. High Pressure Processing (HPP) employs intense pressure to inactivate pathogens without heat, maintaining fresh taste and nutritional quality. Choosing between pasteurization and HPP depends on balancing product safety, shelf life, and sensory attributes.

Table of Comparison

| Feature | Pasteurization | High Pressure Processing (HPP) |

|---|---|---|

| Process | Heat treatment to kill pathogens | Application of high pressure to inactivate microbes |

| Temperature | Typically 60-85degC | Room temperature to 50degC |

| Time | Seconds to minutes | 1-5 minutes |

| Effect on Nutrients | Some nutrient degradation | Preserves nutrients better |

| Flavor Impact | May alter taste | Maintains original flavor |

| Shelf Life Extension | Moderate | Extended, up to several weeks |

| Microbial Safety | Effective against most pathogens | Highly effective, including vegetative cells |

| Energy Consumption | High, due to heating | Lower, no heating required |

| Common Applications | Milk, juice, beer | Juice, smoothies, ready-to-drink beverages |

Introduction to Beverage Preservation Methods

Pasteurization and High Pressure Processing (HPP) are key beverage preservation methods that extend shelf life by reducing microbial load while maintaining quality. Pasteurization uses heat to eliminate pathogens but can affect flavor and nutrient profiles, whereas HPP utilizes intense pressure to inactivate microbes without heat, preserving sensory and nutritional attributes. Both techniques are widely applied in juice, dairy, and ready-to-drink beverages to enhance safety and consumer acceptability.

Understanding Pasteurization in Beverages

Pasteurization in beverages involves heating liquids to specific temperatures, typically between 60degC and 85degC, to eliminate harmful microorganisms while preserving taste and nutritional value. This method effectively extends shelf life by targeting pathogens such as Listeria, Salmonella, and E. coli without significant impact on vitamins and flavor compounds. Compared to High Pressure Processing (HPP), pasteurization uses thermal energy rather than pressure, making it widely applied for products like milk, juice, and beer due to its cost-effectiveness and established safety profile.

What is High Pressure Processing (HPP)?

High Pressure Processing (HPP) is a non-thermal food preservation method that uses extremely high pressure, up to 600 MPa, to inactivate harmful bacteria, yeasts, molds, and viruses in beverages without compromising flavor or nutritional value. This technique extends shelf life and maintains freshness by preserving vitamins, antioxidants, and natural taste profiles better than traditional pasteurization. HPP is especially effective for cold-pressed juices, smoothies, and other sensitive drink products requiring minimal heat exposure to retain quality and health benefits.

Pasteurization vs HPP: Mechanisms Explained

Pasteurization uses heat to inactivate pathogens and enzymes by denaturing proteins, ensuring beverage safety and extended shelf life. High Pressure Processing (HPP) applies intense pressure uniformly to disrupt microbial cell membranes without heat, preserving flavor and nutrients. Both methods target microbial inactivation, with pasteurization relying on thermal effects and HPP utilizing pressure-induced structural damage.

Impact on Beverage Safety and Shelf Life

Pasteurization uses heat to eliminate pathogens in beverages, effectively extending shelf life by reducing microbial load but sometimes altering flavor and nutritional quality. High Pressure Processing (HPP) preserves taste, texture, and nutrients by applying intense pressure to inactivate microbes without heat, resulting in a fresher product with an extended shelf life comparable to pasteurized drinks. Both methods enhance beverage safety, but HPP offers a superior preservation of sensory and nutritional attributes while maintaining microbial stability.

Nutritional and Sensory Differences

Pasteurization, a heat-based method, can cause slight nutrient loss and alter the flavor profile of beverages, often resulting in a cooked taste. High Pressure Processing (HPP) preserves vitamins, antioxidants, and natural flavors more effectively by using intense pressure without heat. Studies show HPP-treated juices retain higher levels of vitamin C and maintain fresh sensory attributes compared to pasteurized counterparts.

Environmental Footprint: Energy and Sustainability

High Pressure Processing (HPP) significantly reduces the environmental footprint compared to traditional pasteurization by consuming up to 40% less energy due to its non-thermal, cold treatment method. Pasteurization relies heavily on continuous heating, leading to higher greenhouse gas emissions and increased water usage. HPP also supports sustainability goals by preserving product quality with minimal additives, reducing food waste through extended shelf life.

Cost Analysis: Pasteurization vs HPP

Pasteurization typically incurs lower upfront equipment costs compared to High Pressure Processing (HPP), making it more accessible for small to mid-sized beverage producers. However, HPP offers longer shelf life and better retention of flavor and nutrients, potentially reducing waste and distribution costs over time. The higher operational and maintenance expenses of HPP often balance out with its ability to command premium pricing in the beverage market.

Consumer Perception and Market Trends

Consumer perception favors High Pressure Processing (HPP) for its ability to preserve natural flavors and nutrients without heat damage, appealing to health-conscious and premium beverage markets. Market trends indicate rapid growth in HPP usage for cold-pressed juices and organic beverages, driven by demand for minimally processed, clean-label products. Pasteurization remains dominant for its cost-effectiveness and established food safety reputation but faces challenges from shifting consumer preferences towards fresher, minimally processed options.

Choosing the Right Processing Method for Your Beverage

Choosing between pasteurization and high pressure processing (HPP) depends on the beverage's sensitivity to heat and desired shelf life. Pasteurization is ideal for products requiring microbial safety through heat treatment, such as juices and milk, ensuring extended shelf stability. HPP preserves nutritional quality and fresh flavor by using ultra-high pressure to inactivate pathogens, making it suitable for premium cold-pressed juices and functional beverages.

Pasteurization vs High Pressure Processing Infographic

productdif.com

productdif.com