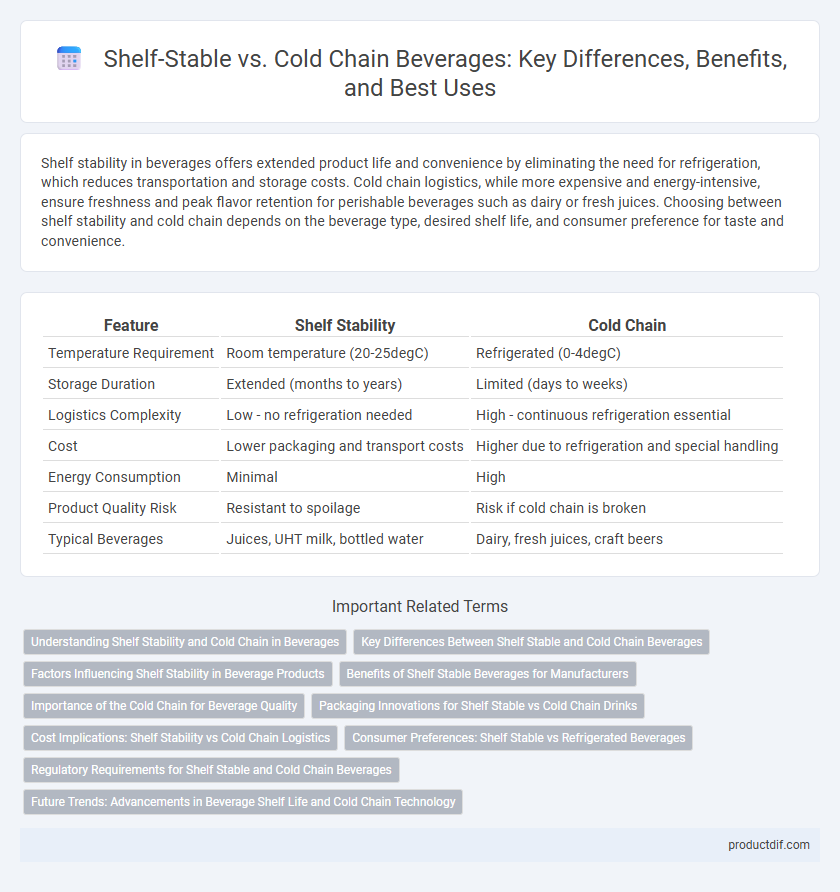

Shelf stability in beverages offers extended product life and convenience by eliminating the need for refrigeration, which reduces transportation and storage costs. Cold chain logistics, while more expensive and energy-intensive, ensure freshness and peak flavor retention for perishable beverages such as dairy or fresh juices. Choosing between shelf stability and cold chain depends on the beverage type, desired shelf life, and consumer preference for taste and convenience.

Table of Comparison

| Feature | Shelf Stability | Cold Chain |

|---|---|---|

| Temperature Requirement | Room temperature (20-25degC) | Refrigerated (0-4degC) |

| Storage Duration | Extended (months to years) | Limited (days to weeks) |

| Logistics Complexity | Low - no refrigeration needed | High - continuous refrigeration essential |

| Cost | Lower packaging and transport costs | Higher due to refrigeration and special handling |

| Energy Consumption | Minimal | High |

| Product Quality Risk | Resistant to spoilage | Risk if cold chain is broken |

| Typical Beverages | Juices, UHT milk, bottled water | Dairy, fresh juices, craft beers |

Understanding Shelf Stability and Cold Chain in Beverages

Shelf stability in beverages refers to the product's ability to remain safe and retain quality without refrigeration for an extended period, typically achieved through pasteurization, sterilization, or the use of preservatives. Cold chain management involves maintaining a controlled, refrigerated environment from production through distribution to preserve perishable beverages like juices and dairy-based drinks. Understanding these concepts helps manufacturers choose appropriate packaging, preservation techniques, and logistics strategies to ensure product safety and extend market reach.

Key Differences Between Shelf Stable and Cold Chain Beverages

Shelf stable beverages are processed and packaged to remain safe and maintain quality at room temperature, relying on sterilization methods such as UHT (Ultra High Temperature) treatment, while cold chain beverages require continuous refrigeration from production to consumption to preserve freshness and prevent microbial growth. Shelf stable products offer extended shelf life and ease of distribution without refrigeration, making them ideal for regions with limited cold storage infrastructure, whereas cold chain beverages provide superior taste and nutritional retention but incur higher logistical costs and energy consumption. The key distinctions lie in temperature control requirements, preservation techniques, supply chain complexity, and consumer convenience.

Factors Influencing Shelf Stability in Beverage Products

Factors influencing shelf stability in beverage products include temperature control, pH levels, and microbial activity. Proper packaging materials, such as oxygen barriers and light-resistant containers, reduce degradation and preserve flavor. Formulation components like preservatives, sugar content, and acidulants also play critical roles in extending shelf life without relying on cold chain logistics.

Benefits of Shelf Stable Beverages for Manufacturers

Shelf stable beverages eliminate the need for refrigerated storage and transportation, significantly reducing logistics and energy costs for manufacturers. These products extend product shelf life without preservatives, allowing broader market distribution and minimizing spoilage-related losses. Enhanced supply chain flexibility and lower carbon footprint also position shelf stable beverages as a sustainable and cost-effective choice in the beverage industry.

Importance of the Cold Chain for Beverage Quality

The cold chain is crucial for preserving the quality and safety of perishable beverages by maintaining consistent, low temperatures throughout storage and transportation. Temperature fluctuations can accelerate microbial growth and chemical changes, leading to spoilage and off-flavors in products such as juices, dairy drinks, and craft beers. Implementing a reliable cold chain system ensures optimal freshness, extended shelf life, and consumer satisfaction by protecting sensitive beverages from deterioration.

Packaging Innovations for Shelf Stable vs Cold Chain Drinks

Advanced packaging innovations for shelf-stable beverages incorporate oxygen scavengers, multi-layer barrier films, and aseptic processing to extend product life without refrigeration. Cold chain drinks benefit from insulated packaging, vacuum insulation panels, and smart temperature indicators to maintain optimal freshness during transportation and storage. These technologies optimize shelf life, reduce spoilage, and enhance consumer convenience by addressing distinct preservation challenges specific to shelf-stable and cold chain beverage categories.

Cost Implications: Shelf Stability vs Cold Chain Logistics

Shelf-stable beverages reduce costs by eliminating the need for refrigeration, lowering energy consumption and simplifying distribution with fewer temperature-controlled storage requirements. Cold chain logistics demand significant investment in refrigerated transport, storage facilities, and continuous temperature monitoring, increasing operational expenses. Choosing shelf stability over cold chain solutions can result in substantial savings and increased supply chain efficiency for beverage manufacturers and retailers.

Consumer Preferences: Shelf Stable vs Refrigerated Beverages

Consumers favor shelf-stable beverages for their convenience, longer shelf life, and reduced need for refrigeration, especially in regions with limited cold chain infrastructure. Refrigerated beverages are preferred for their perceived freshness, enhanced taste, and premium quality, driving demand in urban markets with reliable cold storage. Market trends reveal a growing segmentation where shelf-stable options dominate impulse purchases and on-the-go consumption, while refrigerated products attract health-conscious and premium-focused consumers.

Regulatory Requirements for Shelf Stable and Cold Chain Beverages

Shelf stable beverages must comply with FDA regulations on acidified foods and pasteurization processes to ensure microbial safety during ambient storage, while cold chain beverages require stringent temperature control monitoring to meet USDA and FDA standards for perishable liquids. Regulatory frameworks mandate precise labeling, including expiration dates and storage instructions, to prevent spoilage and protect consumer health across distribution channels. Compliance with these standards involves regular inspections, hazard analysis, and critical control points (HACCP) documentation tailored to the beverage type and storage method.

Future Trends: Advancements in Beverage Shelf Life and Cold Chain Technology

Emerging technologies in beverage preservation are extending shelf life through advanced packaging materials and natural preservatives that maintain quality without refrigeration. Innovations in cold chain logistics, including IoT-enabled temperature monitoring and AI-driven predictive analytics, enhance product freshness and reduce spoilage during distribution. Future trends indicate a convergence of shelf stability improvements and smart cold chain solutions to optimize beverage safety, sustainability, and consumer convenience.

Shelf Stability vs Cold Chain Infographic

productdif.com

productdif.com