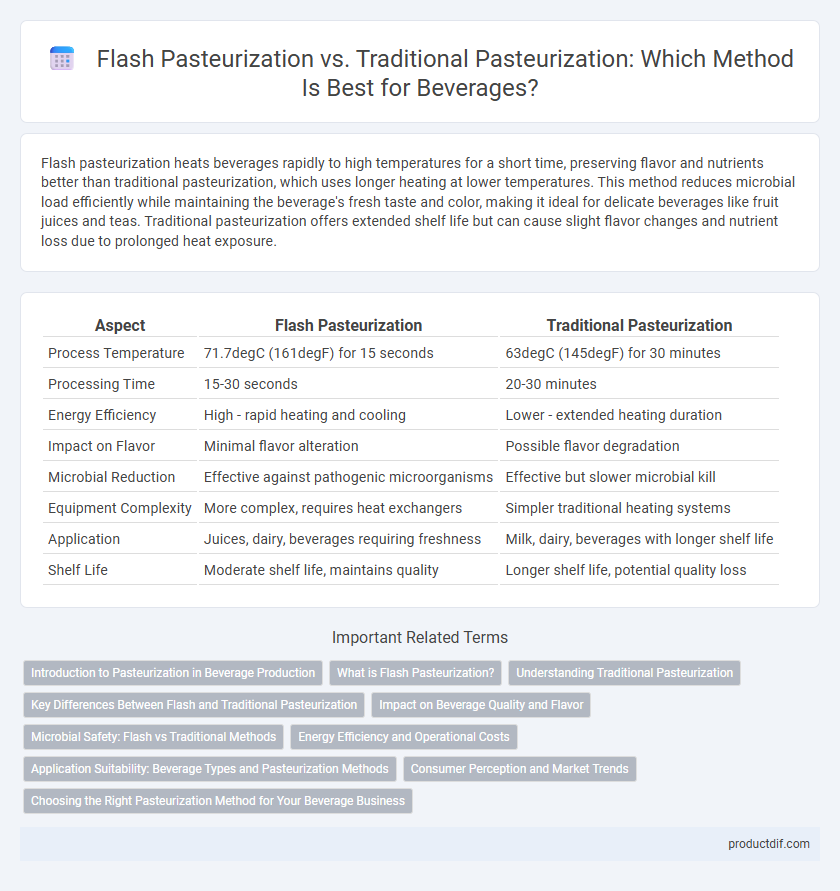

Flash pasteurization heats beverages rapidly to high temperatures for a short time, preserving flavor and nutrients better than traditional pasteurization, which uses longer heating at lower temperatures. This method reduces microbial load efficiently while maintaining the beverage's fresh taste and color, making it ideal for delicate beverages like fruit juices and teas. Traditional pasteurization offers extended shelf life but can cause slight flavor changes and nutrient loss due to prolonged heat exposure.

Table of Comparison

| Aspect | Flash Pasteurization | Traditional Pasteurization |

|---|---|---|

| Process Temperature | 71.7degC (161degF) for 15 seconds | 63degC (145degF) for 30 minutes |

| Processing Time | 15-30 seconds | 20-30 minutes |

| Energy Efficiency | High - rapid heating and cooling | Lower - extended heating duration |

| Impact on Flavor | Minimal flavor alteration | Possible flavor degradation |

| Microbial Reduction | Effective against pathogenic microorganisms | Effective but slower microbial kill |

| Equipment Complexity | More complex, requires heat exchangers | Simpler traditional heating systems |

| Application | Juices, dairy, beverages requiring freshness | Milk, dairy, beverages with longer shelf life |

| Shelf Life | Moderate shelf life, maintains quality | Longer shelf life, potential quality loss |

Introduction to Pasteurization in Beverage Production

Pasteurization in beverage production is a crucial process designed to eliminate harmful microorganisms and extend shelf life while preserving flavor and nutritional value. Flash pasteurization rapidly heats liquids to high temperatures for a short time, enhancing efficiency and maintaining beverage quality compared to traditional pasteurization, which involves longer exposure to moderate heat. This method is widely used in juice, milk, and craft beer industries where freshness and taste retention are prioritized alongside safety.

What is Flash Pasteurization?

Flash pasteurization, also known as high-temperature short-time (HTST) pasteurization, rapidly heats beverages to 71.7degC (161degF) for 15 seconds before quickly cooling them to preserve flavor and nutritional value while eliminating harmful pathogens. This method contrasts with traditional pasteurization, which involves longer heating times at lower temperatures, potentially affecting taste and nutrient retention. Flash pasteurization is commonly used in juice, milk, and craft beer production to ensure safety without compromising quality.

Understanding Traditional Pasteurization

Traditional pasteurization involves heating beverages to a specific temperature, typically around 63degC (145degF) for 30 minutes or 72degC (161degF) for 15 seconds, to kill harmful microorganisms and extend shelf life. This method, also known as batch pasteurization, ensures thorough microbial inactivation but can impact the beverage's flavor and nutritional content due to prolonged heat exposure. Despite these effects, traditional pasteurization remains widely used for its reliability and simplicity in processing dairy products, juices, and other beverages.

Key Differences Between Flash and Traditional Pasteurization

Flash pasteurization heats beverages to 161degF (72degC) for 15 seconds, preserving more flavor and nutrients compared to traditional pasteurization, which uses lower temperatures (140degF/60degC) for 30 minutes. The rapid heating and cooling in flash pasteurization minimize thermal damage and extend shelf life, making it ideal for juices, milk, and craft beverages. Traditional pasteurization, although effective for pathogen reduction, often results in a cooked taste and nutrient loss due to prolonged heating.

Impact on Beverage Quality and Flavor

Flash pasteurization preserves beverage quality by rapidly heating and cooling, minimizing nutrient loss and retaining fresh flavor profiles compared to traditional pasteurization. Traditional pasteurization often causes extended heat exposure, which can degrade delicate flavors and alter the sensory characteristics of beverages like juices and dairy products. Choosing flash pasteurization enhances shelf life while maintaining a more natural taste, crucial for premium beverage brands emphasizing freshness.

Microbial Safety: Flash vs Traditional Methods

Flash pasteurization rapidly heats beverages to temperatures around 71.7degC (161degF) for 15 seconds, effectively eliminating pathogenic microorganisms while preserving flavor and nutrients. Traditional pasteurization involves heating at lower temperatures, typically 60-65degC (140-149degF) for 30 minutes or longer, which can reduce microbial load but may allow heat-resistant spores to survive. Flash pasteurization offers superior microbial safety by minimizing thermal damage and targeting harmful microbes more efficiently compared to traditional methods.

Energy Efficiency and Operational Costs

Flash pasteurization consumes significantly less energy compared to traditional pasteurization due to its shorter heating duration and rapid cooling process, resulting in lower operational costs for beverage producers. The reduced thermal exposure in flash pasteurization minimizes energy waste and extends equipment lifespan, contributing to cost savings. Beverage manufacturers benefit from improved energy efficiency, making flash pasteurization a more sustainable and economically advantageous choice.

Application Suitability: Beverage Types and Pasteurization Methods

Flash pasteurization suits heat-sensitive beverages like fruit juices and craft beers by applying brief high-temperature treatment to preserve flavor and nutrients. Traditional pasteurization, with longer heat exposure at lower temperatures, is ideal for dairy products and beverages requiring extended shelf life and microbial safety. Choosing the appropriate pasteurization method depends on the beverage's thermal sensitivity, desired shelf life, and quality preservation needs.

Consumer Perception and Market Trends

Flash pasteurization is viewed favorably by consumers seeking fresher taste and higher nutritional retention in beverages compared to traditional pasteurization, which is often associated with longer shelf life but perceived flavor loss. Market trends indicate a growing demand for minimally processed drinks, driving beverage producers to adopt flash pasteurization for its ability to balance safety and quality. This shift aligns with consumer preferences for clean-label products and enhanced sensory experiences, influencing product innovation and marketing strategies in the beverage industry.

Choosing the Right Pasteurization Method for Your Beverage Business

Flash pasteurization offers rapid heating and cooling, preserving flavor and nutritional quality, making it ideal for delicate beverages like fruit juices and craft beers. Traditional pasteurization uses longer heat exposure to ensure microbial safety, suitable for products requiring extended shelf life such as dairy drinks and canned beverages. Selecting the right method depends on your beverage's sensitivity to heat, desired shelf life, and production scale to maintain quality while meeting safety standards.

Flash Pasteurization vs Traditional Pasteurization Infographic

productdif.com

productdif.com