Water-based inks offer a softer feel and superior environmental benefits compared to plastisol inks, making them ideal for eco-conscious apparel brands. Plastisol inks provide vibrant colors and durable prints but contain PVC and require heat curing, which can impact sustainability. Choosing between these inks hinges on balancing print quality, garment feel, and environmental impact.

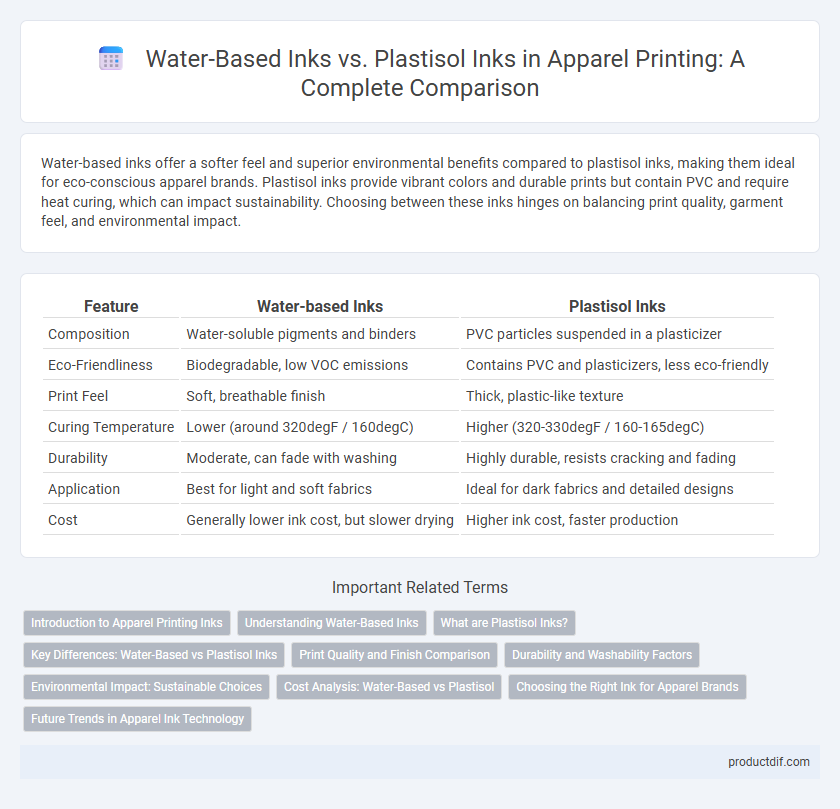

Table of Comparison

| Feature | Water-based Inks | Plastisol Inks |

|---|---|---|

| Composition | Water-soluble pigments and binders | PVC particles suspended in a plasticizer |

| Eco-Friendliness | Biodegradable, low VOC emissions | Contains PVC and plasticizers, less eco-friendly |

| Print Feel | Soft, breathable finish | Thick, plastic-like texture |

| Curing Temperature | Lower (around 320degF / 160degC) | Higher (320-330degF / 160-165degC) |

| Durability | Moderate, can fade with washing | Highly durable, resists cracking and fading |

| Application | Best for light and soft fabrics | Ideal for dark fabrics and detailed designs |

| Cost | Generally lower ink cost, but slower drying | Higher ink cost, faster production |

Introduction to Apparel Printing Inks

Water-based inks offer eco-friendly, soft-to-the-touch prints that penetrate fabric fibers, making them ideal for breathable apparel designs. Plastisol inks provide vibrant, durable colors with superior opacity, widely favored for intricate and bold garment graphics. Choosing between these inks impacts print feel, environmental footprint, and design longevity in apparel production.

Understanding Water-Based Inks

Water-based inks offer a sustainable and eco-friendly alternative to plastisol inks, utilizing water as a carrier instead of PVC and phthalates. These inks penetrate fabric fibers, resulting in softer prints with enhanced breathability and durability suitable for high-quality apparel. Water-based inks require specific curing temperatures and techniques to ensure vibrant colors and long-lasting adherence on cotton and blended textiles.

What are Plastisol Inks?

Plastisol inks are a popular choice in apparel printing due to their vibrant colors and excellent durability on fabrics. Composed primarily of PVC particles suspended in a plasticizer, these inks do not dry until heat-cured, allowing for precise designs and long-lasting prints. Their ability to produce thick, opaque layers makes them ideal for dark garments and intricate artwork.

Key Differences: Water-Based vs Plastisol Inks

Water-based inks penetrate fabric fibers, resulting in a softer feel and better breathability, making them ideal for lightweight garments and eco-friendly prints. Plastisol inks sit on top of the fabric, providing vibrant colors and excellent opacity, which ensures durability and a longer-lasting print. The key differences lie in their environmental impact, texture, and curing process, with water-based inks requiring lower heat and producing less VOC emissions compared to plastisol.

Print Quality and Finish Comparison

Water-based inks offer a soft, breathable finish with excellent color vibrancy that enhances print quality on lighter fabrics, creating a smooth, eco-friendly texture. Plastisol inks provide a durable, opaque finish suitable for vibrant prints on dark garments, maintaining color integrity over multiple washes. While water-based inks yield a more natural feel, plastisol inks deliver superior coverage and resistance, ideal for complex designs requiring sharp details.

Durability and Washability Factors

Water-based inks provide a softer print with superior breathability, but they tend to have lower durability and may fade quicker after multiple washes compared to plastisol inks. Plastisol inks offer excellent durability and maintain vibrant colors through extensive wash cycles, making them ideal for long-term apparel use. For designs requiring longevity and consistent washability, plastisol inks are generally preferred over water-based alternatives.

Environmental Impact: Sustainable Choices

Water-based inks significantly reduce environmental impact by minimizing the release of harmful volatile organic compounds (VOCs) during the apparel printing process. Plastisol inks, derived from PVC and containing phthalates, pose higher ecological risks due to their non-biodegradable nature and the requirement for chemical solvents in cleanup. Choosing water-based inks supports sustainable apparel production by promoting biodegradability and lowering toxic waste in garment manufacturing.

Cost Analysis: Water-Based vs Plastisol

Water-based inks typically incur higher upfront costs due to longer drying times and specialized equipment requirements, but they offer cost savings in reduced environmental compliance fees and easier cleanup. Plastisol inks, while generally cheaper per print and faster to cure, may lead to increased expenses related to solvent-based waste disposal and potential health regulations. Evaluating overall cost efficiency depends on print volume, environmental policies, and long-term sustainability goals within the apparel production process.

Choosing the Right Ink for Apparel Brands

Water-based inks offer eco-friendly benefits and softer prints, making them ideal for brands prioritizing sustainability and comfort. Plastisol inks provide vibrant colors and durability, perfect for designs requiring boldness and longevity. Apparel brands should assess their design needs, fabric types, and environmental values to choose the ink that aligns with their brand identity and production goals.

Future Trends in Apparel Ink Technology

Water-based inks are gaining momentum in apparel printing due to their eco-friendly properties, biodegradability, and softer hand feel compared to plastisol inks. Technological advancements are enhancing color vibrancy and durability of water-based inks, making them a preferred choice for sustainable fashion brands. Innovations in water-based ink formulations and curing processes indicate a promising shift towards environmentally responsible, high-performance apparel printing solutions.

Water-based inks vs Plastisol inks Infographic

productdif.com

productdif.com