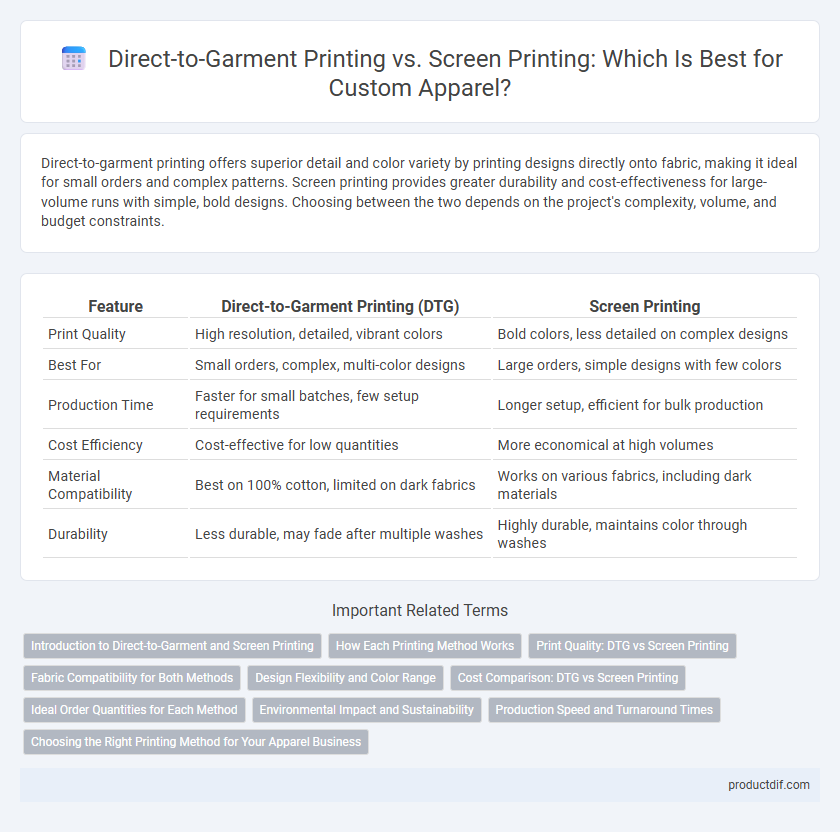

Direct-to-garment printing offers superior detail and color variety by printing designs directly onto fabric, making it ideal for small orders and complex patterns. Screen printing provides greater durability and cost-effectiveness for large-volume runs with simple, bold designs. Choosing between the two depends on the project's complexity, volume, and budget constraints.

Table of Comparison

| Feature | Direct-to-Garment Printing (DTG) | Screen Printing |

|---|---|---|

| Print Quality | High resolution, detailed, vibrant colors | Bold colors, less detailed on complex designs |

| Best For | Small orders, complex, multi-color designs | Large orders, simple designs with few colors |

| Production Time | Faster for small batches, few setup requirements | Longer setup, efficient for bulk production |

| Cost Efficiency | Cost-effective for low quantities | More economical at high volumes |

| Material Compatibility | Best on 100% cotton, limited on dark fabrics | Works on various fabrics, including dark materials |

| Durability | Less durable, may fade after multiple washes | Highly durable, maintains color through washes |

Introduction to Direct-to-Garment and Screen Printing

Direct-to-garment (DTG) printing utilizes advanced inkjet technology to apply high-resolution designs directly onto fabric, enabling intricate color gradients and rapid production for small to medium batches. Screen printing involves creating stencils (screens) for each color, allowing specialized inks to be pressed through onto the fabric, renowned for durability and vibrant colors in large volume runs. Both methods offer unique benefits depending on design complexity, order size, and garment type within apparel manufacturing.

How Each Printing Method Works

Direct-to-garment (DTG) printing uses inkjet technology to spray water-based inks directly onto fabric, allowing for highly detailed, full-color designs with minimal setup. Screen printing involves creating stencil screens for each color, then pressing ink through the mesh onto the garment, which produces vibrant, durable prints ideal for large orders. DTG excels in complex, multicolor patterns and small batches, while screen printing is cost-effective for mass production and simple color designs.

Print Quality: DTG vs Screen Printing

Direct-to-garment (DTG) printing offers unparalleled detail and color vibrancy, making it ideal for complex, multi-colored designs on apparel. Screen printing excels in producing durable, bold prints with solid color opacity, especially on large runs where consistency is key. While DTG provides soft, breathable prints with fine gradients, screen printing remains superior for achieving long-lasting prints on darker fabrics.

Fabric Compatibility for Both Methods

Direct-to-garment (DTG) printing excels on 100% cotton fabrics due to its water-based inks that bond effectively with natural fibers, producing vibrant and detailed images. Screen printing offers broader fabric compatibility, including cotton, polyester, and cotton-poly blends, utilizing durable plastisol or water-based inks that adhere well to both natural and synthetic materials. Choosing between DTG and screen printing depends on the fabric type and desired print durability, with screen printing favored for versatile fabric options and DTG ideal for high-quality prints on pure cotton garments.

Design Flexibility and Color Range

Direct-to-garment (DTG) printing offers superior design flexibility by enabling intricate, full-color images with unlimited color variations and gradients directly on fabric, making it ideal for detailed artwork and small batches. Screen printing excels in vibrant, solid colors with high durability but is limited to fewer colors per design due to the need for separate screens, making complex multicolor prints more time-consuming and costly. DTG's digital process supports seamless color transitions and photorealistic prints, while screen printing remains a cost-effective choice for high-volume orders with simpler color palettes.

Cost Comparison: DTG vs Screen Printing

Direct-to-garment (DTG) printing typically incurs higher costs per unit for small batches due to its detailed ink application and limited setup expenses. Screen printing offers lower costs for large volumes by distributing the initial stencil and setup fees over many items, making it more economical for bulk production. Evaluating order size and design complexity is essential to determine which method provides the best cost efficiency for apparel printing projects.

Ideal Order Quantities for Each Method

Direct-to-garment printing excels with small to medium order quantities, typically ranging from 1 to 100 pieces, due to minimal setup costs and the ability to print complex designs with vibrant colors directly onto fabric. Screen printing is more cost-effective for large orders, generally starting around 50 to 500 pieces, as its initial setup involves creating screens but results in lower cost per unit at scale. Choosing the ideal order quantity depends on factors like design complexity, color count, and budget constraints, with DTG favored for custom, low-volume runs and screen printing optimized for bulk production.

Environmental Impact and Sustainability

Direct-to-garment (DTG) printing reduces water usage by up to 90% compared to traditional screen printing, minimizing chemical waste and energy consumption. Screen printing generates more plastic waste from screens and higher levels of water pollution due to ink runoff. DTG's eco-friendly digital process supports sustainable apparel production by decreasing resource depletion and toxic emissions.

Production Speed and Turnaround Times

Direct-to-garment (DTG) printing offers significantly faster production speed for small batches and custom designs due to its digital process, eliminating setup times required in screen printing. Screen printing excels in high-volume orders with quicker turnaround times once screens are prepared, but initial setup can delay production. Brands balancing speed and volume often choose DTG for rapid prototyping and limited runs, while screen printing remains optimal for bulk apparel production.

Choosing the Right Printing Method for Your Apparel Business

Direct-to-garment (DTG) printing offers high detail and vibrant colors ideal for small runs and complex designs, while screen printing excels in cost efficiency and durability for bulk orders with simpler color schemes. Evaluating order volume, design complexity, and budget constraints helps determine the optimal method for your apparel business. Leveraging DTG for on-demand prints and screen printing for large-scale production maximizes both quality and profitability.

Direct-to-garment printing vs Screen printing Infographic

productdif.com

productdif.com