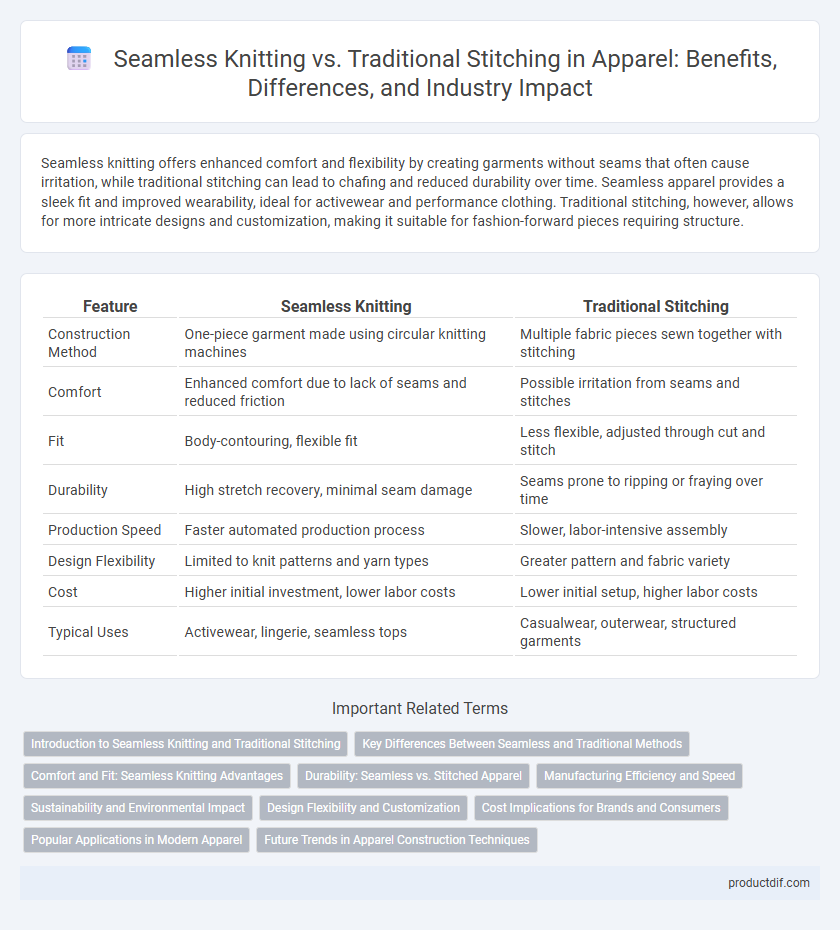

Seamless knitting offers enhanced comfort and flexibility by creating garments without seams that often cause irritation, while traditional stitching can lead to chafing and reduced durability over time. Seamless apparel provides a sleek fit and improved wearability, ideal for activewear and performance clothing. Traditional stitching, however, allows for more intricate designs and customization, making it suitable for fashion-forward pieces requiring structure.

Table of Comparison

| Feature | Seamless Knitting | Traditional Stitching |

|---|---|---|

| Construction Method | One-piece garment made using circular knitting machines | Multiple fabric pieces sewn together with stitching |

| Comfort | Enhanced comfort due to lack of seams and reduced friction | Possible irritation from seams and stitches |

| Fit | Body-contouring, flexible fit | Less flexible, adjusted through cut and stitch |

| Durability | High stretch recovery, minimal seam damage | Seams prone to ripping or fraying over time |

| Production Speed | Faster automated production process | Slower, labor-intensive assembly |

| Design Flexibility | Limited to knit patterns and yarn types | Greater pattern and fabric variety |

| Cost | Higher initial investment, lower labor costs | Lower initial setup, higher labor costs |

| Typical Uses | Activewear, lingerie, seamless tops | Casualwear, outerwear, structured garments |

Introduction to Seamless Knitting and Traditional Stitching

Seamless knitting is an innovative apparel manufacturing technique that creates garments without visible seams, enhancing comfort and fit by eliminating chafing and pressure points. Traditional stitching involves sewing separate fabric pieces together, often resulting in seams that can affect garment flexibility and durability. The seamless process uses circular knitting machines to produce a single-piece garment, while the traditional method relies on cutting and stitching multiple panels, impacting production efficiency and design complexity.

Key Differences Between Seamless and Traditional Methods

Seamless knitting utilizes advanced circular knitting machines to create garments in one continuous piece, eliminating side seams and reducing fabric waste compared to traditional stitching, which involves cutting and sewing multiple fabric panels. Seamless apparel offers enhanced comfort and flexibility due to the absence of bulky seams, whereas traditional stitched garments may cause friction and discomfort at seam lines. Production efficiency is higher in seamless knitting, enabling faster manufacturing and better garment fit customization, while traditional stitching allows for more design complexity with various fabric types.

Comfort and Fit: Seamless Knitting Advantages

Seamless knitting technology eliminates seams, reducing friction and irritation on the skin, which significantly enhances comfort in apparel. The construction provides a more precise and adaptive fit by contouring naturally to the body's shape, unlike traditional stitching that can create rigid or bulky areas. This results in garments that offer superior flexibility and freedom of movement, making seamless knitwear ideal for activewear and everyday comfort.

Durability: Seamless vs. Stitched Apparel

Seamless knitting enhances durability by eliminating stitched seams that often become weak points and prone to wear and tear. Traditional stitching, while structurally supportive, can cause fabric stress and eventual fraying along seam lines, reducing garment longevity. Apparel made with seamless technology offers consistent fabric integrity and improved resistance to stretching and abrasion, extending the lifespan of activewear and performance clothing.

Manufacturing Efficiency and Speed

Seamless knitting significantly enhances manufacturing efficiency by producing garments in one continuous process, eliminating the need for multiple stitching stages and reducing labor costs. This method accelerates production speed, enabling faster turnaround times compared to traditional stitching that involves assembling separate fabric pieces with labor-intensive seams. Brands leveraging seamless technology benefit from streamlined supply chains and lower material waste, resulting in more cost-effective and sustainable apparel manufacturing.

Sustainability and Environmental Impact

Seamless knitting reduces fabric waste by producing garments in a single piece, eliminating the need for cutting and sewing, which minimizes offcuts and scrap material. Traditional stitching involves multiple fabric panels and sewing steps, generating significant textile waste and increasing energy consumption during production. Seamless technology also lowers water and chemical usage, making it a more sustainable choice in apparel manufacturing.

Design Flexibility and Customization

Seamless knitting offers superior design flexibility by allowing intricate patterns, shapes, and gradients to be integrated directly into the fabric without interruption, unlike traditional stitching which relies on piecing separate components together. This technology enables precise customization in fit and style, reducing material waste and enhancing garment comfort through a single continuous piece. Traditional stitching limits customization due to fixed panel sizes and seam placements, often resulting in less adaptable designs and potential discomfort from seams.

Cost Implications for Brands and Consumers

Seamless knitting significantly reduces material waste and labor costs compared to traditional stitching, enabling brands to optimize production expenses. Consumers often benefit from lower prices and improved garment comfort due to the elasticity and fit offered by seamless designs. However, the initial investment in specialized machinery for seamless knitting may increase up-front costs for brands, influencing pricing strategies.

Popular Applications in Modern Apparel

Seamless knitting is widely used in activewear and athleisure due to its flexibility, comfort, and reduced chafing, making it ideal for workout garments and yoga wear. Traditional stitching remains prevalent in formal wear and tailored clothing because it provides structured seams and precise fit customization. Both techniques are integral to modern apparel, with seamless knitting driving innovation in performance fabrics while traditional stitching supports classic designs.

Future Trends in Apparel Construction Techniques

Seamless knitting technology is revolutionizing apparel construction by enabling the creation of garments with minimal to no seams, enhancing fit, comfort, and performance. Future trends indicate increased adoption of 3D knitting machines and automated production lines, reducing waste and boosting sustainability in fashion manufacturing. Traditional stitching methods will continue to evolve but are likely to integrate with digital technology to meet rising consumer demand for customization and eco-friendly apparel.

Seamless knitting vs Traditional stitching Infographic

productdif.com

productdif.com