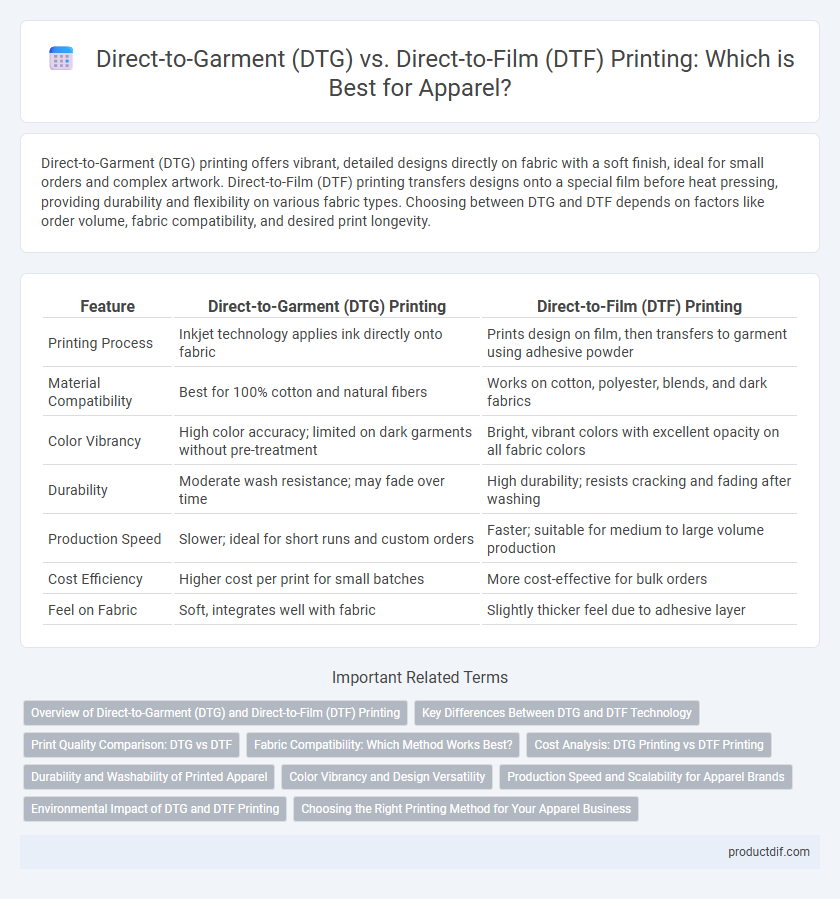

Direct-to-Garment (DTG) printing offers vibrant, detailed designs directly on fabric with a soft finish, ideal for small orders and complex artwork. Direct-to-Film (DTF) printing transfers designs onto a special film before heat pressing, providing durability and flexibility on various fabric types. Choosing between DTG and DTF depends on factors like order volume, fabric compatibility, and desired print longevity.

Table of Comparison

| Feature | Direct-to-Garment (DTG) Printing | Direct-to-Film (DTF) Printing |

|---|---|---|

| Printing Process | Inkjet technology applies ink directly onto fabric | Prints design on film, then transfers to garment using adhesive powder |

| Material Compatibility | Best for 100% cotton and natural fibers | Works on cotton, polyester, blends, and dark fabrics |

| Color Vibrancy | High color accuracy; limited on dark garments without pre-treatment | Bright, vibrant colors with excellent opacity on all fabric colors |

| Durability | Moderate wash resistance; may fade over time | High durability; resists cracking and fading after washing |

| Production Speed | Slower; ideal for short runs and custom orders | Faster; suitable for medium to large volume production |

| Cost Efficiency | Higher cost per print for small batches | More cost-effective for bulk orders |

| Feel on Fabric | Soft, integrates well with fabric | Slightly thicker feel due to adhesive layer |

Overview of Direct-to-Garment (DTG) and Direct-to-Film (DTF) Printing

Direct-to-Garment (DTG) printing applies ink directly onto fabric using specialized inkjet technology, allowing for high-resolution, full-color designs with a soft hand feel ideal for small batch or custom apparel production. Direct-to-Film (DTF) printing transfers designs onto a specialized film which is then heat-pressed onto garments, offering vibrant colors, durability, and compatibility with various fabrics including cotton, polyester, and blends. Both methods provide efficient solutions for apparel customization, but DTG excels in detailed, photo-quality prints on natural fibers while DTF supports versatility and cost-effective mass production.

Key Differences Between DTG and DTF Technology

Direct-to-Garment (DTG) printing applies ink directly onto fabric fibers, resulting in vibrant colors and a soft finish ideal for cotton materials, while Direct-to-Film (DTF) printing transfers designs onto a special film before heat-pressing them onto various fabrics, offering greater versatility across different textile blends. DTG requires pre-treatment for optimal ink absorption and functions best with light-colored garments, whereas DTF eliminates color restrictions and provides durable prints suitable for dark and synthetic fabrics. Production speed also contrasts, with DTF enabling faster turnaround times and bulk printing efficiency compared to the more detailed and slower DTG process.

Print Quality Comparison: DTG vs DTF

Direct-to-Garment (DTG) printing delivers vibrant, high-resolution prints with excellent detail and smooth color gradients, ideal for complex designs on cotton fabrics. Direct-to-Film (DTF) printing offers versatile adhesion across various fabric types and produces durable prints with sharp edges, though the color vibrancy may slightly lag behind DTG. Overall, DTG excels in print quality on natural fibers, while DTF provides strong performance on diverse textiles with consistent durability.

Fabric Compatibility: Which Method Works Best?

Direct-to-Garment (DTG) printing excels on 100% cotton fabrics, offering vibrant, detailed prints with excellent color absorption, making it ideal for natural fibers. Direct-to-Film (DTF) printing provides superior versatility, working efficiently on a wide range of materials including cotton blends, polyester, and nylon, without compromising print durability. For fabric compatibility, DTF is the preferred method when printing on diverse textile blends, while DTG remains the best choice for pure cotton garments.

Cost Analysis: DTG Printing vs DTF Printing

Direct-to-Garment (DTG) printing generally incurs higher upfront costs due to specialized ink and printer maintenance, while Direct-to-Film (DTF) printing offers lower initial expenses and greater affordability for small batch runs. DTF printing reduces consumable costs by using more economical powders and films, making it cost-effective for large volume apparel production with consistent quality. Businesses seeking scalable solutions often favor DTF for its balance of lower material costs and faster turnaround times compared to the price-intensive DTG process.

Durability and Washability of Printed Apparel

Direct-to-Garment (DTG) printing offers vibrant, detailed designs but may experience fading and cracking over multiple washes, especially on darker fabrics. Direct-to-Film (DTF) printing applies durable ink films that resist cracking and color degradation, maintaining print integrity through frequent laundering. Overall, DTF provides superior washability and long-term durability for printed apparel compared to DTG techniques.

Color Vibrancy and Design Versatility

Direct-to-Garment (DTG) printing delivers superior color vibrancy with its ability to print complex, full-color designs directly onto fabric, ensuring sharp and bright images ideal for detailed artwork. Direct-to-Film (DTF) printing offers greater design versatility, enabling transfers on various fabric types and colors while maintaining durability and color integrity through heat-activated adhesive films. Both techniques optimize garment customization, but DTG excels in vivid color reproduction, whereas DTF provides flexibility across diverse apparel materials.

Production Speed and Scalability for Apparel Brands

Direct-to-Garment (DTG) printing offers faster production speeds for small to medium runs, enabling apparel brands to quickly fulfill customized orders with minimal setup time. Direct-to-Film (DTF) printing scales more efficiently for larger production volumes, providing consistent quality and durability while reducing costs per unit. Apparel brands benefit from DTG for rapid prototyping and niche designs, whereas DTF supports mass production with scalable output and streamlined workflow.

Environmental Impact of DTG and DTF Printing

Direct-to-Garment (DTG) printing typically involves water-based inks that are biodegradable and produce less chemical waste, contributing to a lower environmental footprint. Direct-to-Film (DTF) printing uses specialized films and powder adhesives, which can generate more plastic waste and consume additional energy during curing processes. Choosing DTG often results in reduced water pollution and chemical runoff, making it a more eco-friendly option in sustainable apparel production.

Choosing the Right Printing Method for Your Apparel Business

Direct-to-Garment (DTG) printing excels in producing vibrant, high-resolution designs on cotton fabrics, making it ideal for small batches and custom orders with complex color details. Direct-to-Film (DTF) printing offers versatility across various fabric types, including polyester, and provides durable prints suitable for large-scale production with consistent quality. Selecting the right method depends on fabric type, order volume, and design complexity, ensuring optimal cost-efficiency and product quality for your apparel business.

Direct-to-Garment Printing vs Direct-to-Film Printing Infographic

productdif.com

productdif.com