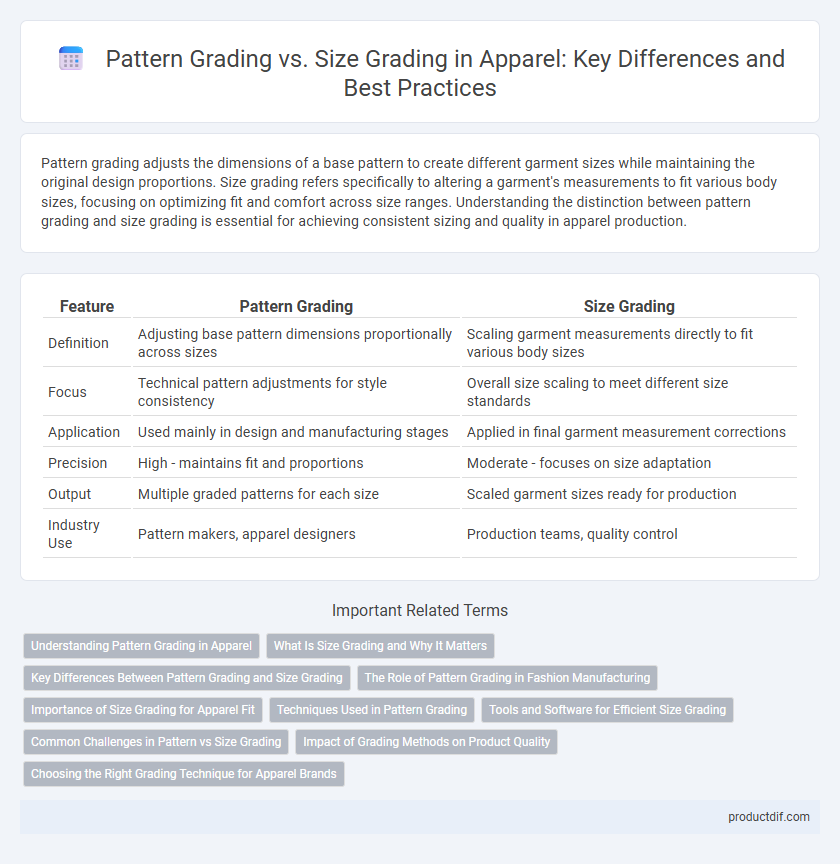

Pattern grading adjusts the dimensions of a base pattern to create different garment sizes while maintaining the original design proportions. Size grading refers specifically to altering a garment's measurements to fit various body sizes, focusing on optimizing fit and comfort across size ranges. Understanding the distinction between pattern grading and size grading is essential for achieving consistent sizing and quality in apparel production.

Table of Comparison

| Feature | Pattern Grading | Size Grading |

|---|---|---|

| Definition | Adjusting base pattern dimensions proportionally across sizes | Scaling garment measurements directly to fit various body sizes |

| Focus | Technical pattern adjustments for style consistency | Overall size scaling to meet different size standards |

| Application | Used mainly in design and manufacturing stages | Applied in final garment measurement corrections |

| Precision | High - maintains fit and proportions | Moderate - focuses on size adaptation |

| Output | Multiple graded patterns for each size | Scaled garment sizes ready for production |

| Industry Use | Pattern makers, apparel designers | Production teams, quality control |

Understanding Pattern Grading in Apparel

Pattern grading in apparel involves systematically adjusting a base design pattern to create multiple sizes while maintaining the garment's proportional fit and style integrity. It requires precise measurement increments based on body dimensions, ensuring each graded pattern reflects consistent shape and structural balance across sizes. Understanding pattern grading enables designers to produce scalable clothing collections that accommodate diverse body types without compromising design aesthetics.

What Is Size Grading and Why It Matters

Size grading is the process of creating a range of garment sizes from a base pattern to ensure consistent fit across different body measurements. It matters because accurate size grading ensures apparel brands meet diverse customer needs, optimize production efficiency, and reduce return rates due to poor fit. In contrast to pattern grading, which modifies design features, size grading focuses on proportional adjustments for standard sizing.

Key Differences Between Pattern Grading and Size Grading

Pattern grading involves adjusting the original design's shape and proportion to create different sizes, ensuring the garment maintains its aesthetic and functional integrity across various size ranges. Size grading focuses specifically on scaling the pattern dimensions up or down based on standardized body measurement increments without altering the fundamental design elements. The key difference lies in pattern grading's emphasis on preserving design details while size grading emphasizes consistent fit adjustments for different body sizes.

The Role of Pattern Grading in Fashion Manufacturing

Pattern grading in fashion manufacturing involves systematically increasing or decreasing the size of a base pattern to create multiple garment sizes, ensuring consistent fit and design proportions across a size range. Unlike size grading, which adjusts dimensions based on standard body measurements, pattern grading carefully modifies the entire pattern shape to maintain garment aesthetics and structural integrity. This process is crucial for optimizing production efficiency and delivering products that meet diverse consumer fit expectations.

Importance of Size Grading for Apparel Fit

Size grading is crucial for achieving consistent apparel fit across different body measurements, ensuring garments accommodate variations in dimensions such as chest, waist, and hips. Unlike pattern grading, which adjusts a base pattern's proportions, size grading systematically scales patterns to create a range of sizes tailored for target consumer demographics. Proper size grading enhances customer satisfaction by delivering well-fitting clothes, reducing return rates and increasing brand loyalty.

Techniques Used in Pattern Grading

Pattern grading techniques in apparel involve digitally scaling base patterns using CAD software to create accurate size variations while maintaining design proportions and fit integrity. Manual pattern grading employs the use of grading rules and measurement increments applied through physical tools like rulers and grading machines to adjust garment dimensions precisely. Advanced methods integrate three-dimensional body scanning data to tailor pattern adjustments for enhanced fit and customization across multiple sizes.

Tools and Software for Efficient Size Grading

Pattern grading relies on specialized CAD software such as Gerber AccuMark and Lectra Modaris, which enable precise manipulation of base patterns for multiple sizes. Size grading tools, including Optitex and Tukatech, optimize fit by applying incremental adjustments to body measurements, ensuring consistency across size charts. These software solutions enhance efficiency in apparel production by automating grading rules and reducing manual errors, accelerating the development cycle.

Common Challenges in Pattern vs Size Grading

Pattern grading often struggles with maintaining design integrity across different sizes, leading to fit inconsistencies and style distortions. Size grading challenges include converting base measurements into scalable proportions without compromising garment shape or comfort. Both processes require precise adjustments to balance aesthetic appeal and functional fit across a size range.

Impact of Grading Methods on Product Quality

Pattern grading ensures precise scaling of design elements, maintaining garment proportions and style integrity across sizes, which directly enhances fit consistency and overall product quality. Size grading primarily adjusts garment dimensions to accommodate different body sizes, but inadequate grading techniques can lead to compromised fit and discomfort. Accurate grading methods minimize fabric waste and production errors, significantly influencing customer satisfaction and brand reputation in the apparel industry.

Choosing the Right Grading Technique for Apparel Brands

Selecting the appropriate grading technique is crucial for apparel brands aiming to balance fit accuracy and production efficiency. Pattern grading adjusts the original design's shape proportionally across sizes to preserve style lines, while size grading modifies measurements to accommodate different body dimensions without altering the base pattern's structure. Brands targeting consistent aesthetics and high-quality fit often prefer pattern grading, whereas those focusing on mass production and varied sizing may opt for size grading to streamline manufacturing processes.

Pattern Grading vs Size Grading Infographic

productdif.com

productdif.com