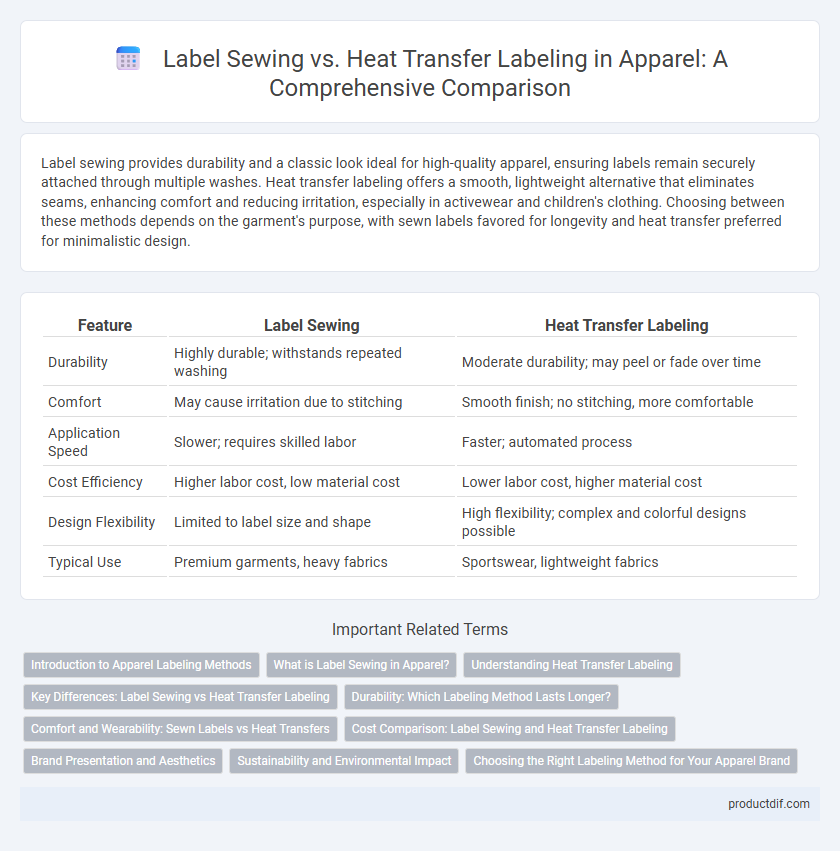

Label sewing provides durability and a classic look ideal for high-quality apparel, ensuring labels remain securely attached through multiple washes. Heat transfer labeling offers a smooth, lightweight alternative that eliminates seams, enhancing comfort and reducing irritation, especially in activewear and children's clothing. Choosing between these methods depends on the garment's purpose, with sewn labels favored for longevity and heat transfer preferred for minimalistic design.

Table of Comparison

| Feature | Label Sewing | Heat Transfer Labeling |

|---|---|---|

| Durability | Highly durable; withstands repeated washing | Moderate durability; may peel or fade over time |

| Comfort | May cause irritation due to stitching | Smooth finish; no stitching, more comfortable |

| Application Speed | Slower; requires skilled labor | Faster; automated process |

| Cost Efficiency | Higher labor cost, low material cost | Lower labor cost, higher material cost |

| Design Flexibility | Limited to label size and shape | High flexibility; complex and colorful designs possible |

| Typical Use | Premium garments, heavy fabrics | Sportswear, lightweight fabrics |

Introduction to Apparel Labeling Methods

Apparel labeling methods primarily include label sewing and heat transfer labeling, each offering unique benefits for garment identification and branding. Label sewing involves stitching fabric labels directly onto garments, providing durability and a traditional look preferred for high-end or care instruction tags. Heat transfer labeling uses heat and pressure to apply printed labels, enabling a seamless, lightweight option ideal for performance wear and minimizing irritation.

What is Label Sewing in Apparel?

Label sewing in apparel involves stitching fabric labels directly onto garments, providing durable branding and care information that withstands repeated washing and wear. This traditional method ensures the label remains securely attached, enhancing garment authenticity and quality perception. Compared to heat transfer labeling, sewn labels offer a tactile, high-end feel preferred by premium clothing brands.

Understanding Heat Transfer Labeling

Heat transfer labeling in apparel involves applying a printed design or label onto fabric using heat and pressure, ensuring a smooth, flexible finish that does not affect garment comfort. This method offers durability, resistance to laundering, and allows for intricate, multi-color designs without adding bulk, making it ideal for athletic and performance wear. Understanding heat transfer labeling helps manufacturers choose between traditional sewn labels and innovative, seamless branding techniques for enhanced aesthetic appeal and wearer comfort.

Key Differences: Label Sewing vs Heat Transfer Labeling

Label sewing in apparel involves stitching fabric tags directly onto garments, offering durability and a premium feel that withstands multiple washes. Heat transfer labeling applies printed designs through heat and pressure, allowing for smooth, flexible labels that do not irritate the skin but may fade over time. Key differences include longevity and tactile experience, with sewn labels excelling in durability and heat transfers favored for seamless comfort and intricate designs.

Durability: Which Labeling Method Lasts Longer?

Label sewing in apparel offers superior durability due to strong stitching that withstands repeated washing and wear without fading or peeling. Heat transfer labeling, while providing a smooth and flexible finish, tends to degrade faster under high-temperature washing and frequent abrasion. For long-lasting garment identification, sewn labels outperform heat transfer methods by maintaining clarity and attachment over extended use.

Comfort and Wearability: Sewn Labels vs Heat Transfers

Sewn labels provide a traditional, durable option but can cause irritation or discomfort due to their stiffness and raised texture against the skin. Heat transfer labeling offers a smooth, lightweight alternative that enhances wearability by eliminating the bulk and scratchiness associated with sewn tags. This method improves overall comfort, especially in activewear and garments designed for sensitive skin.

Cost Comparison: Label Sewing and Heat Transfer Labeling

Label sewing typically incurs higher labor and material costs due to the manual or machine stitching process, making it more expensive for small production runs. Heat transfer labeling offers a cost-effective alternative with lower setup and application expenses, especially advantageous for large quantities or complex designs. Evaluating the total cost impact involves considering durability, production volume, and design complexity to choose the most economical labeling method.

Brand Presentation and Aesthetics

Label sewing enhances brand presentation by offering a tactile, premium feel that conveys durability and craftsmanship, making it ideal for high-end apparel. Heat transfer labeling provides a sleek, smooth finish that maintains fabric flexibility and is perfect for activewear or minimalist designs where comfort and modern aesthetics matter. Both techniques influence the visual appeal and consumer perception, with sewn labels emphasizing tradition and quality, while heat transfers promote innovation and streamlined branding.

Sustainability and Environmental Impact

Label sewing in apparel typically offers greater sustainability due to its durability and reduced need for frequent replacement, minimizing waste over the garment's lifespan. Heat transfer labeling often involves synthetic adhesives that can release volatile organic compounds (VOCs) and hinder garment recyclability, contributing to environmental pollution. Choosing sewn labels with natural fibers and eco-friendly threads supports lower carbon footprints and enhances apparel recyclability.

Choosing the Right Labeling Method for Your Apparel Brand

Choosing the right labeling method for your apparel brand depends on factors such as fabric type, production volume, and brand aesthetics. Label sewing ensures durability and a premium feel, ideal for high-end or intricate designs, while heat transfer labeling offers a smooth finish and flexibility suitable for activewear and mass production. Evaluating customer comfort, cost-effectiveness, and label longevity helps determine the optimal approach for enhancing brand identity and garment functionality.

Label sewing vs Heat transfer labeling Infographic

productdif.com

productdif.com