Heat transfer labels offer a smooth, lightweight finish ideal for activewear and garments requiring minimal irritation against the skin, while woven labels provide durability and a premium tactile feel suited for high-quality apparel. Heat transfer labels are resistant to fading and maintain sharp graphics after repeated washes, making them perfect for vibrant branding. Woven labels, crafted from threads, excel in adding a classic, textured look that enhances brand perception and garment authenticity.

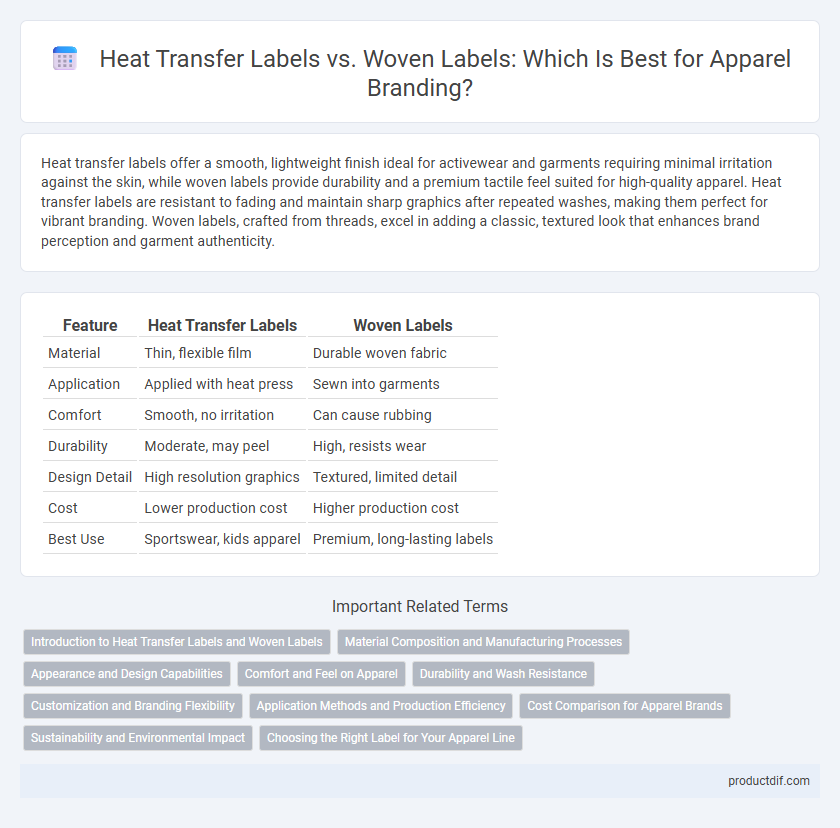

Table of Comparison

| Feature | Heat Transfer Labels | Woven Labels |

|---|---|---|

| Material | Thin, flexible film | Durable woven fabric |

| Application | Applied with heat press | Sewn into garments |

| Comfort | Smooth, no irritation | Can cause rubbing |

| Durability | Moderate, may peel | High, resists wear |

| Design Detail | High resolution graphics | Textured, limited detail |

| Cost | Lower production cost | Higher production cost |

| Best Use | Sportswear, kids apparel | Premium, long-lasting labels |

Introduction to Heat Transfer Labels and Woven Labels

Heat transfer labels are thin, flexible labels applied to fabric using heat and pressure, offering a seamless and lightweight alternative to traditional tags. Woven labels, made from interlaced threads, provide durability and a high-quality texture, allowing detailed designs and branding elements to stand out. Both label types serve as essential branding tools in apparel manufacturing, each with unique advantages for garment aesthetics and comfort.

Material Composition and Manufacturing Processes

Heat transfer labels are made from polyurethane or polyester materials that are printed with specialized inks and then heat-pressed onto fabric, allowing for a smooth, flexible, and lightweight application ideal for activewear. Woven labels consist of threads such as polyester, cotton, or nylon intricately woven on jacquard looms, producing a durable and textured label with sharper detail and longevity. Manufacturing heat transfer labels involves a digital or screen printing process combined with heat application, while woven labels require complex weaving techniques and finishing steps like cutting and heat-sealing to prevent fraying.

Appearance and Design Capabilities

Heat transfer labels offer seamless application with no added bulk, allowing for intricate designs, vibrant colors, and fine details that enhance garment aesthetics without compromising fabric texture. Woven labels provide a classic, textured appearance with durable threading, ideal for logos and text requiring longevity and a tactile quality. The choice between heat transfer and woven labels depends on design complexity, desired durability, and the overall look tailored to brand identity.

Comfort and Feel on Apparel

Heat transfer labels provide a smooth, tagless experience that enhances wearer comfort by eliminating bulky fabric tags often found with woven labels. Woven labels, while durable and visually detailed, can cause irritation or discomfort due to their thickness and stiffness against the skin. Apparel designers balance durability with wearability by selecting heat transfer labels for softness and seamless integration in performance or casual wear.

Durability and Wash Resistance

Heat transfer labels offer excellent wash resistance by adhering directly to the fabric, minimizing peeling and fading during frequent laundering. Woven labels, constructed from tightly woven threads, provide superior durability and maintain clarity after numerous washes but may cause slight fabric irritation. Both label types deliver long-lasting performance, with heat transfer labels favoring smooth surfaces and woven labels excelling in robust applications requiring tactile strength.

Customization and Branding Flexibility

Heat transfer labels offer superior customization and branding flexibility by allowing intricate designs, vibrant colors, and variable sizing directly applied to garments without added bulk. Woven labels provide durability and a premium tactile feel but often have limitations in color gradients and design complexity compared to heat transfer options. Brands seeking versatile, lightweight, and detailed logo placement frequently prefer heat transfer labels for enhanced visual impact and seamless integration.

Application Methods and Production Efficiency

Heat transfer labels apply through heat and pressure, enabling fast, seamless integration ideal for curved or delicate fabrics without added bulk. Woven labels require sewing, which increases production time but offers durability and a premium tactile feel. Heat transfer labels enhance production efficiency by reducing labor and minimizing garment handling, whereas woven labels demand more manual processes and longer lead times for complex designs.

Cost Comparison for Apparel Brands

Heat transfer labels typically offer lower production and application costs compared to woven labels, making them an economical choice for mass apparel brands aiming to reduce manufacturing expenses. Woven labels, while more durable and premium in appearance, involve higher setup fees and longer lead times, which can increase overall costs, especially for small-batch orders. Apparel brands must weigh the upfront cost savings of heat transfer labels against the longevity and brand perception advantages provided by woven labels when making label sourcing decisions.

Sustainability and Environmental Impact

Heat transfer labels reduce fabric waste and energy consumption during production compared to woven labels, making them a more sustainable choice for eco-conscious apparel brands. Woven labels use traditional weaving processes that consume more water and generate higher emissions, impacting environmental sustainability negatively. Choosing heat transfer labels supports reduced carbon footprints and lowers resource use in garment manufacturing, aligning with green fashion initiatives.

Choosing the Right Label for Your Apparel Line

When choosing the right label for your apparel line, consider heat transfer labels for their smooth, tagless comfort and seamless integration with fabric, ideal for activewear and performance garments. Woven labels offer durability and a premium, textured feel, making them perfect for high-end or artisanal clothing lines where brand visibility and tactile quality are priorities. Selection depends on fabric type, garment use, and brand identity to ensure the label enhances both wearability and aesthetic appeal.

Heat Transfer Labels vs Woven Labels Infographic

productdif.com

productdif.com