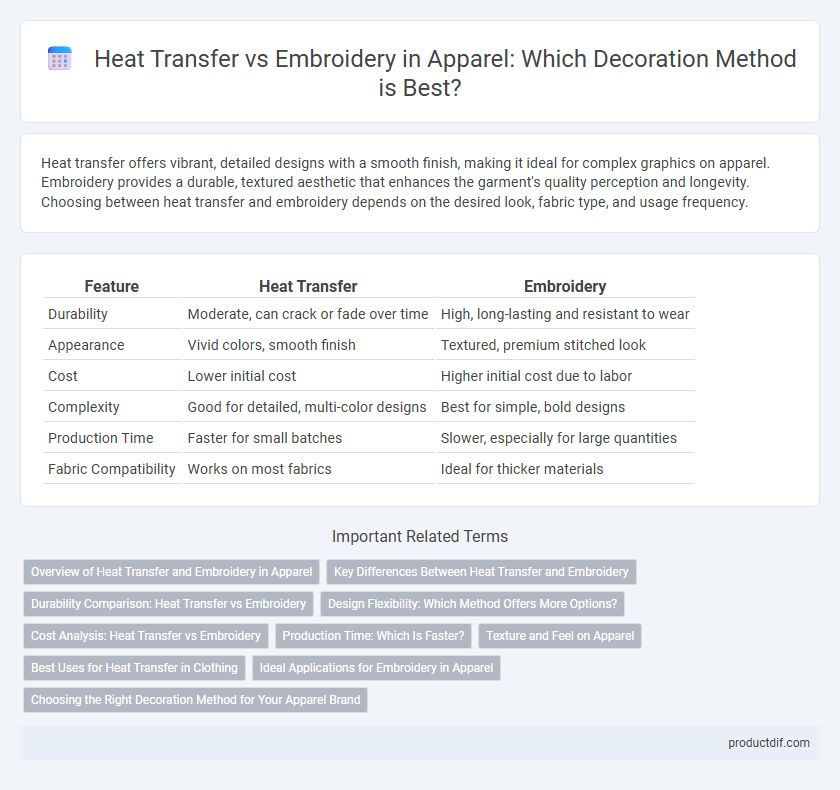

Heat transfer offers vibrant, detailed designs with a smooth finish, making it ideal for complex graphics on apparel. Embroidery provides a durable, textured aesthetic that enhances the garment's quality perception and longevity. Choosing between heat transfer and embroidery depends on the desired look, fabric type, and usage frequency.

Table of Comparison

| Feature | Heat Transfer | Embroidery |

|---|---|---|

| Durability | Moderate, can crack or fade over time | High, long-lasting and resistant to wear |

| Appearance | Vivid colors, smooth finish | Textured, premium stitched look |

| Cost | Lower initial cost | Higher initial cost due to labor |

| Complexity | Good for detailed, multi-color designs | Best for simple, bold designs |

| Production Time | Faster for small batches | Slower, especially for large quantities |

| Fabric Compatibility | Works on most fabrics | Ideal for thicker materials |

Overview of Heat Transfer and Embroidery in Apparel

Heat transfer in apparel uses heat and pressure to apply printed designs or logos onto fabric, offering vibrant colors and quick production for complex images. Embroidery involves stitching threads directly into the fabric, providing a textured, durable finish ideal for logos and designs requiring longevity and a premium appearance. Both methods enhance garment customization but differ in cost, texture, and suitability for various fabric types.

Key Differences Between Heat Transfer and Embroidery

Heat transfer uses a printed vinyl or ink design applied with heat and pressure, offering vibrant colors and detailed graphics ideal for complex images and small runs. Embroidery involves stitching threads directly into fabric, providing a textured, durable finish suited for logos or text that require a premium, long-lasting appearance. Heat transfer is faster and cost-effective for short runs, while embroidery excels in longevity and a professional look for higher quantities.

Durability Comparison: Heat Transfer vs Embroidery

Embroidery offers superior durability compared to heat transfer, with stitched threads holding up well against repeated washing and wear. Heat transfer designs, often made from vinyl or printed films, tend to degrade faster, showing signs of cracking or peeling over time. For long-lasting apparel customization, embroidery remains the preferred choice due to its robust stitching and resistance to fading.

Design Flexibility: Which Method Offers More Options?

Heat transfer provides greater design flexibility with the ability to reproduce intricate, full-color graphics and gradients that are difficult to achieve with embroidery. Embroidery offers a textured, durable finish but is limited by thread colors and stitch patterns, making it less suitable for highly detailed or photographic designs. For complex, multi-colored artwork, heat transfer remains the preferred choice, while embroidery excels in classic, durable logos and text.

Cost Analysis: Heat Transfer vs Embroidery

Heat transfer offers a lower initial investment with minimal setup costs, making it ideal for small orders and budget-conscious projects, while embroidery requires higher upfront expenses due to equipment and digitizing fees but provides superior durability and a premium finish. The per-unit cost of heat transfer decreases with volume, yet embroidery remains more cost-effective for large-scale production because of its long-lasting quality and resistance to wear. Evaluating cost analysis between heat transfer and embroidery involves balancing budget constraints, order size, and desired garment longevity.

Production Time: Which Is Faster?

Heat transfer offers significantly faster production times than embroidery, completing designs in minutes due to its digital printing process. Embroidery involves stitching each element, requiring more time depending on the complexity and size of the design. For bulk orders with simple graphics, heat transfer is the optimal choice to maximize efficiency and speed.

Texture and Feel on Apparel

Heat transfer offers a smooth, lightweight finish that adheres closely to fabric, preserving the garment's original texture with minimal added thickness. Embroidery creates a raised, tactile texture with stitched threads, adding durability and a premium feel that stands out visually and physically on apparel. Choosing between the two depends on the desired texture, with heat transfer favoring sleekness and embroidery providing a rich, textured dimension.

Best Uses for Heat Transfer in Clothing

Heat transfer is ideal for detailed, multicolor designs on athletic wear, promotional t-shirts, and custom uniforms, offering vibrant colors and smooth finishes on polyester and cotton blends. This method excels in producing small runs or personalized items quickly with lower setup costs compared to embroidery. Heat transfer is best used for lightweight fabrics requiring flexibility and fine graphic detail, especially in fashion and sports apparel.

Ideal Applications for Embroidery in Apparel

Embroidery is ideal for durable, high-quality apparel customization, especially on items like polo shirts, jackets, hats, and uniforms where long-lasting, textured designs are preferred. It excels in branding for corporate wear, sports team apparel, and promotional merchandise due to its professional appearance and resistance to fading and peeling. Embroidery is particularly suited for thicker fabrics and structured garments, providing a premium, three-dimensional look that enhances garment value.

Choosing the Right Decoration Method for Your Apparel Brand

Heat transfer offers vibrant, detailed designs with quick turnaround times, ideal for small runs or complex graphics, while embroidery provides durability and a premium, textured finish that enhances brand perception. Selecting the right decoration method depends on factors like fabric type, budget, design complexity, and desired longevity of the apparel. For apparel brands aiming to combine cost-efficiency with high-quality visuals, hybrid strategies using both heat transfer and embroidery can optimize brand impact and product appeal.

Heat transfer vs embroidery Infographic

productdif.com

productdif.com