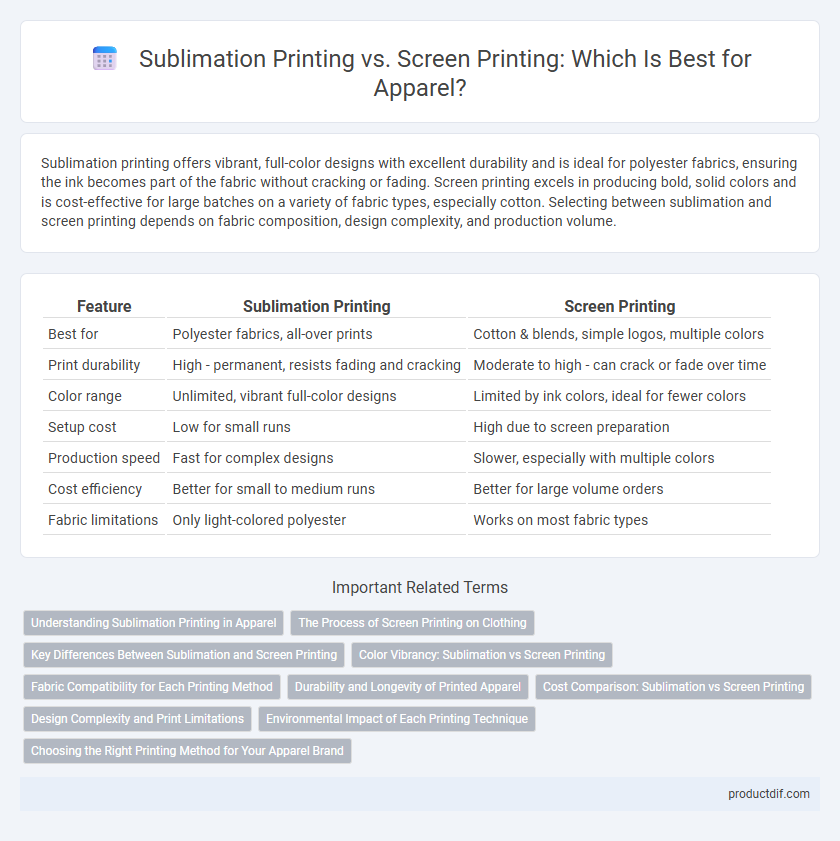

Sublimation printing offers vibrant, full-color designs with excellent durability and is ideal for polyester fabrics, ensuring the ink becomes part of the fabric without cracking or fading. Screen printing excels in producing bold, solid colors and is cost-effective for large batches on a variety of fabric types, especially cotton. Selecting between sublimation and screen printing depends on fabric composition, design complexity, and production volume.

Table of Comparison

| Feature | Sublimation Printing | Screen Printing |

|---|---|---|

| Best for | Polyester fabrics, all-over prints | Cotton & blends, simple logos, multiple colors |

| Print durability | High - permanent, resists fading and cracking | Moderate to high - can crack or fade over time |

| Color range | Unlimited, vibrant full-color designs | Limited by ink colors, ideal for fewer colors |

| Setup cost | Low for small runs | High due to screen preparation |

| Production speed | Fast for complex designs | Slower, especially with multiple colors |

| Cost efficiency | Better for small to medium runs | Better for large volume orders |

| Fabric limitations | Only light-colored polyester | Works on most fabric types |

Understanding Sublimation Printing in Apparel

Sublimation printing in apparel uses heat to transfer dye onto polyester fabrics, producing vibrant, long-lasting colors that penetrate the fibers instead of sitting on the surface. This method delivers excellent durability and colorfastness, making it ideal for sportswear and custom fashion where detailed, full-color designs are needed. Unlike screen printing, sublimation is limited to light-colored, synthetic materials but excels in producing seamless, high-resolution images without cracking or fading over time.

The Process of Screen Printing on Clothing

Screen printing on clothing involves creating a stencil, or screen, and using it to apply layers of ink directly onto fabric. This method allows for vibrant, durable designs by pressing ink through the mesh screen and onto the apparel surface, with each color added separately. The ink is then cured using heat to ensure longevity and resistance to washing and fading.

Key Differences Between Sublimation and Screen Printing

Sublimation printing infuses dye directly into polyester fabrics, resulting in vibrant, durable, and lightweight designs ideal for intricate, full-color images. Screen printing uses stencils and layers of ink for bold, opaque prints suited to simple designs and diverse fabric types like cotton. Sublimation offers better colorfastness and detail on synthetic materials, while screen printing excels in versatility and cost-effectiveness for bulk orders on natural fibers.

Color Vibrancy: Sublimation vs Screen Printing

Sublimation printing delivers unparalleled color vibrancy by infusing dye directly into polyester fabrics, resulting in vivid, long-lasting hues that resist fading and cracking. Screen printing, while capable of producing bold colors on various materials, often struggles with color vibrancy on lighter fabrics and may show signs of wear over time. For apparel requiring bright, durable colors on synthetic fabrics, sublimation printing consistently outperforms screen printing in maintaining vibrant, high-resolution designs.

Fabric Compatibility for Each Printing Method

Sublimation printing works best on polyester fabrics or polyester-coated materials, where it infuses ink directly into synthetic fibers, resulting in vibrant, durable designs that won't crack or fade. Screen printing is highly versatile, compatible with a wide range of fabrics including cotton, polyester, and blends, making it ideal for heavier textiles and creating bold, opaque designs. Understanding the fabric compatibility helps brands select the optimal printing method for durability, color vibrancy, and garment type.

Durability and Longevity of Printed Apparel

Sublimation printing infuses ink directly into polyester fibers, creating vibrant designs that resist fading, cracking, and peeling over time, making it ideal for long-lasting apparel. Screen printing applies thick layers of ink onto fabric surfaces, offering strong durability especially on cotton, but may experience gradual wear, including fading and cracking after repeated washing. For extended longevity, sublimation excels on synthetic materials, while screen printing remains a robust choice for natural fibers with proper care.

Cost Comparison: Sublimation vs Screen Printing

Sublimation printing typically involves higher initial equipment costs but offers lower per-unit expenses for complex, full-color designs, making it cost-effective for small to medium runs. Screen printing demands lower startup costs but incurs higher expenses with color separations and setup fees, benefiting large-volume orders due to economies of scale. For apparel businesses, choosing between sublimation and screen printing depends on order size and design complexity to optimize overall production cost.

Design Complexity and Print Limitations

Sublimation printing excels in producing intricate, full-color designs with unlimited color variations and gradient effects, making it ideal for complex patterns on polyester fabrics. Screen printing, while cost-effective for large runs, faces limitations in color layers and intricate details due to mesh screen constraints, resulting in less precision and color blending challenges. Both methods have unique strengths, but sublimation offers superior performance for highly detailed, multicolor apparel designs.

Environmental Impact of Each Printing Technique

Sublimation printing uses water-based inks and generates minimal waste, making it an eco-friendly option with lower emissions and reduced chemical usage compared to screen printing. Screen printing produces higher volumes of chemical waste and uses plastisol inks containing PVC and phthalates, which are harmful to the environment if not disposed of properly. Choosing sublimation printing supports sustainable apparel production by significantly reducing water pollution and energy consumption.

Choosing the Right Printing Method for Your Apparel Brand

Sublimation printing offers vibrant, full-color designs ideal for polyester fabrics and detailed graphics, making it perfect for brands prioritizing high-resolution prints and durability. Screen printing excels with bold, solid colors and is more cost-effective for large volume orders on cotton fabrics, providing a classic, long-lasting finish. Apparel brands should evaluate fabric type, design complexity, order size, and budget to select the printing method that aligns with their quality standards and production needs.

Sublimation printing vs screen printing Infographic

productdif.com

productdif.com