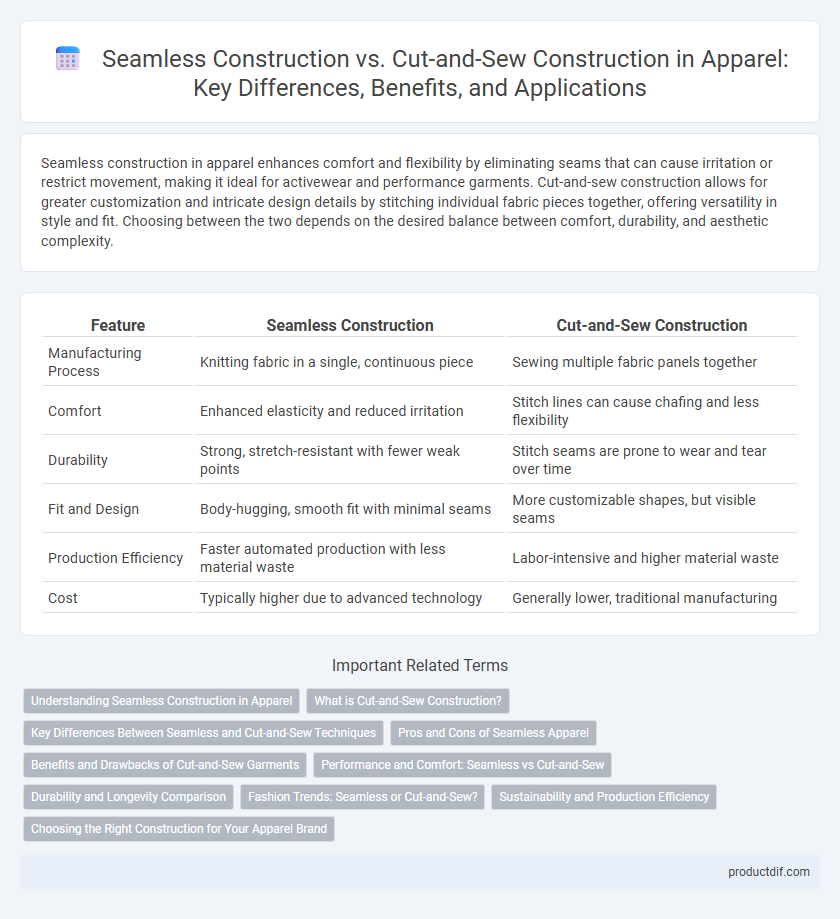

Seamless construction in apparel enhances comfort and flexibility by eliminating seams that can cause irritation or restrict movement, making it ideal for activewear and performance garments. Cut-and-sew construction allows for greater customization and intricate design details by stitching individual fabric pieces together, offering versatility in style and fit. Choosing between the two depends on the desired balance between comfort, durability, and aesthetic complexity.

Table of Comparison

| Feature | Seamless Construction | Cut-and-Sew Construction |

|---|---|---|

| Manufacturing Process | Knitting fabric in a single, continuous piece | Sewing multiple fabric panels together |

| Comfort | Enhanced elasticity and reduced irritation | Stitch lines can cause chafing and less flexibility |

| Durability | Strong, stretch-resistant with fewer weak points | Stitch seams are prone to wear and tear over time |

| Fit and Design | Body-hugging, smooth fit with minimal seams | More customizable shapes, but visible seams |

| Production Efficiency | Faster automated production with less material waste | Labor-intensive and higher material waste |

| Cost | Typically higher due to advanced technology | Generally lower, traditional manufacturing |

Understanding Seamless Construction in Apparel

Seamless construction in apparel utilizes advanced knitting technology to create garments without traditional stitched seams, enhancing comfort and fit by reducing friction and irritation on the skin. This technique allows for greater flexibility and durability, making it ideal for activewear and performance clothing where movement and breathability are crucial. Brands leveraging seamless construction benefit from streamlined manufacturing processes and sustainable production by minimizing fabric waste compared to cut-and-sew methods.

What is Cut-and-Sew Construction?

Cut-and-sew construction is a traditional apparel manufacturing method where individual fabric pieces are precisely cut and then stitched together to form garments. This technique allows for complex designs, multiple fabric types, and detailed tailoring, offering greater versatility in fit and style. Brands often use cut-and-sew methods for custom, high-quality apparel such as tailored suits, dresses, and activewear with intricate seam placements.

Key Differences Between Seamless and Cut-and-Sew Techniques

Seamless construction utilizes circular knitting machines to produce garments without stitched seams, offering enhanced comfort, flexibility, and reduced chafing, ideal for activewear and performance apparel. Cut-and-sew construction involves cutting pre-made fabric pieces and sewing them together, allowing for more complex designs, varied fabric combinations, and precise fitting adjustments. Seamless techniques improve durability by eliminating weak points at seams, whereas cut-and-sew provides greater customization and structure through traditional stitching methods.

Pros and Cons of Seamless Apparel

Seamless apparel offers superior comfort by eliminating bulky seams, which reduces skin irritation and provides a smoother fit ideal for activewear and performance clothing. The technology allows for enhanced flexibility and durability due to continuous fabric knitting, but production costs are higher, limiting design complexity and customization compared to cut-and-sew garments. Challenges include limited fabric patterns and restricted styles, making seamless apparel less versatile for diverse fashion applications despite its ergonomic advantages.

Benefits and Drawbacks of Cut-and-Sew Garments

Cut-and-sew garments offer precise pattern customization and enhanced design versatility, allowing for intricate detailing and tailored fits that are difficult to achieve with seamless construction. However, the increased labor and multiple fabric pieces often result in higher production costs and potential discomfort due to visible seams. Despite these drawbacks, cut-and-sew remains favored for its ability to produce complex, structured apparel with distinct style elements.

Performance and Comfort: Seamless vs Cut-and-Sew

Seamless construction enhances performance and comfort by eliminating stitches and seams, reducing skin irritation and providing a smooth, second-skin fit ideal for activewear. Cut-and-sew construction offers tailored fit options with precise shaping but may cause friction and discomfort during intense movement due to seam placement. Advanced seamless technology improves breathability and flexibility, making it superior for high-performance apparel focused on comfort.

Durability and Longevity Comparison

Seamless construction enhances durability by eliminating stitched seams, reducing points of wear and potential tear, which extends garment longevity. Cut-and-sew construction involves multiple stitched pieces, making seams susceptible to fraying and weakening over time, especially under frequent stress. High-quality seamless apparel often maintains structural integrity longer, providing better long-term performance compared to traditional cut-and-sew garments.

Fashion Trends: Seamless or Cut-and-Sew?

Seamless construction is gaining momentum in fashion trends due to its smooth fit, enhanced comfort, and reduced fabric waste, making it ideal for activewear and athleisure collections. Cut-and-sew construction remains popular for its versatility, allowing intricate designs and customization in high-end fashion garments. Brands increasingly blend seamless technology with traditional cut-and-sew methods to create innovative apparel that meets both style and performance demands.

Sustainability and Production Efficiency

Seamless construction minimizes fabric waste and reduces energy consumption by eliminating additional sewing steps, making it a more sustainable option compared to traditional cut-and-sew methods. Cut-and-sew construction often involves more material waste due to pattern cutting and multiple assembly processes, impacting overall production efficiency. Brands adopting seamless technology benefit from faster manufacturing cycles and lower environmental footprints, aligning with sustainable apparel trends.

Choosing the Right Construction for Your Apparel Brand

Seamless construction offers enhanced comfort and durability by eliminating stitched seams, making it ideal for performance-focused and athleisure apparel brands. Cut-and-sew construction provides greater design flexibility and customization, allowing for intricate patterns and precise fit adjustments perfect for fashion-forward and bespoke clothing lines. Selecting the right construction method depends on brand priorities such as comfort, design complexity, production volume, and target market preferences.

Seamless Construction vs Cut-and-Sew Construction Infographic

productdif.com

productdif.com