Panel construction in apparel involves stitching together separate fabric pieces to enhance fit and design precision, offering greater customization compared to cut-and-sew methods. Cut-and-sew refers to the basic process of cutting fabric from a pattern and sewing it into finished garments, suitable for mass production but often less tailored. Choosing panel construction can improve garment durability and aesthetic appeal by allowing more complex shapes and contouring.

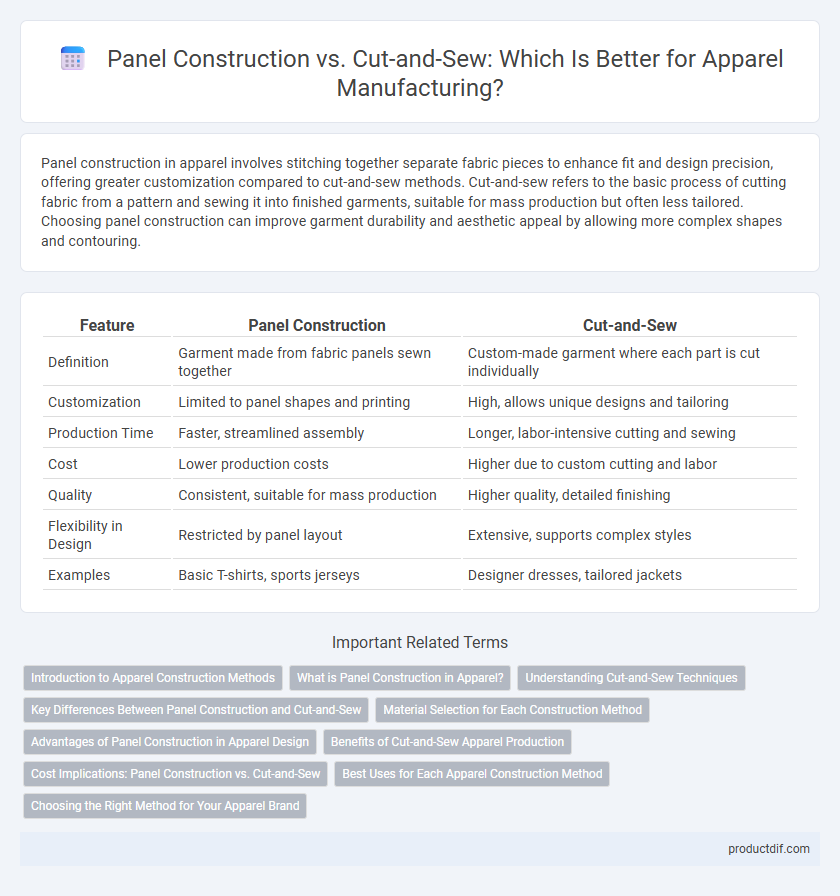

Table of Comparison

| Feature | Panel Construction | Cut-and-Sew |

|---|---|---|

| Definition | Garment made from fabric panels sewn together | Custom-made garment where each part is cut individually |

| Customization | Limited to panel shapes and printing | High, allows unique designs and tailoring |

| Production Time | Faster, streamlined assembly | Longer, labor-intensive cutting and sewing |

| Cost | Lower production costs | Higher due to custom cutting and labor |

| Quality | Consistent, suitable for mass production | Higher quality, detailed finishing |

| Flexibility in Design | Restricted by panel layout | Extensive, supports complex styles |

| Examples | Basic T-shirts, sports jerseys | Designer dresses, tailored jackets |

Introduction to Apparel Construction Methods

Panel construction in apparel involves sewing together pre-cut fabric panels, allowing for precise shaping and detailed design elements that enhance fit and durability. Cut-and-sew methods use individually cut fabric pieces tailored to specific garment patterns, offering greater customization and versatility in styles. Both techniques are foundational in apparel manufacturing, balancing efficiency with the ability to create varied garment structures.

What is Panel Construction in Apparel?

Panel construction in apparel involves assembling a garment from multiple fabric pieces, or panels, sewn together to create shape and fit. This method allows for precise control over fabric placement, pattern alignment, and design details, resulting in enhanced durability and tailored aesthetics. Compared to cut-and-sew techniques, panel construction often supports complex garment structures and more intricate design elements.

Understanding Cut-and-Sew Techniques

Cut-and-sew techniques involve creating individual garment pieces from fabric and sewing them together, allowing for precise tailoring and complex designs. This method enables customization of fit, pattern alignment, and fabric choices, resulting in higher-quality apparel compared to panel construction. Mastery of cut-and-sew techniques is essential for producing detailed garments with durability and professional finishes in the fashion industry.

Key Differences Between Panel Construction and Cut-and-Sew

Panel construction involves assembling pre-cut fabric pieces sewn together to create a garment, ensuring precise shapes and patterns with less material waste. Cut-and-sew refers to the process where individual fabric panels are custom-cut and stitched, offering greater design flexibility and suitability for complex garments. The key difference lies in production efficiency and design adaptability, with panel construction favoring standardized shapes and cut-and-sew allowing intricate designs and variations.

Material Selection for Each Construction Method

Panel construction typically utilizes larger fabric sections, which allows for more consistent material grain alignment and minimizes fabric waste, making it ideal for solid colors and patterns requiring uniformity. Cut-and-sew methods involve assembling smaller, distinct fabric pieces, offering greater flexibility to mix diverse materials such as knits, wovens, and technical fabrics for enhanced functionality and aesthetic detail. Material selection in panel construction prioritizes durability and fabric stability, while cut-and-sew emphasizes versatility and precision to accommodate complex designs and performance attributes.

Advantages of Panel Construction in Apparel Design

Panel construction in apparel design offers enhanced fit precision by allowing designers to shape garments with greater control over fabric placement and contouring, resulting in improved comfort and silhouette definition. This method reduces material waste through strategic panel sizing and cutting, which supports sustainable production practices. Additionally, panel construction simplifies the integration of complex patterns and textures, enabling more creative and high-quality designs compared to traditional cut-and-sew techniques.

Benefits of Cut-and-Sew Apparel Production

Cut-and-sew apparel production offers unparalleled design flexibility by allowing precise control over fabric selection, pattern placement, and garment fit, resulting in higher-quality finished products. This method supports complex construction techniques and customization, catering to niche markets and brand-specific aesthetics. Additionally, cut-and-sew processes reduce fabric waste and enable efficient use of diverse materials, enhancing sustainability in apparel manufacturing.

Cost Implications: Panel Construction vs. Cut-and-Sew

Panel construction often reduces production costs by simplifying assembly processes and minimizing fabric waste compared to traditional cut-and-sew methods, which require individual pattern pieces and detailed stitching. Cut-and-sew techniques demand higher labor intensity and longer production time, driving up expenses especially for custom or complex designs. Apparel manufacturers must balance cost efficiency with design flexibility when choosing between panel construction and cut-and-sew approaches.

Best Uses for Each Apparel Construction Method

Panel construction excels in creating seamless designs with efficient fabric usage, making it ideal for sportswear and activewear where stretch and comfort are priorities. Cut-and-sew offers precise tailoring and design flexibility, best suited for custom-fitted garments like suits and high-end fashion. Choosing between these methods depends on the desired fit, fabric type, and production scale.

Choosing the Right Method for Your Apparel Brand

Panel construction offers precise control over garment shape through sewn fabric pieces, ideal for intricate designs and custom fits, while cut-and-sew excels in scalability and versatility for mass production with consistent quality. Selecting the right method depends on your brand's focus, production volume, and desired aesthetic, balancing cost efficiency and design complexity. Brands targeting niche markets or bespoke apparel often prefer panel construction, whereas those prioritizing high-volume distribution lean towards cut-and-sew techniques.

Panel Construction vs Cut-and-Sew Infographic

productdif.com

productdif.com